- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- inspection systems

Results for

Inspection systems - Import export

BIZERBA SE & CO. KG

Germany

Efficient control of packaging and label content in labeling lines The Bizerba LabelSecure vision inspection system automatically checks label position and texts. Bizerba LabelSecure can be integrated in conveyor lines with dynamic checkweighers. Thereby offering a high level of flexibility and adaptability to existing systems. Used with an inline dynamic checkweigher the system will add another level of protection on your production line. Consider the Dynamic checkweigher CWEmaxx. The system will checkweigh and reject any over filled and under filled packages. In addition, the vision inspection system performance is impressive, automatic control of label position, texts and film colour. Any packages that do not conform to the programmed or set criteria will be rejected. Also, package sizes and bar codes are verifiable. All packages that fall outside of the date range set up in the Vision Inspection System will be rejected, Ensuring out of date or short sell by dated products...

Request for a quote

BIZERBA SE & CO. KG

Germany

Complete optical packaging inspection Vision inspection system SealSecure checks the seal and seams on the package, labels and information on the top and bottom or the sides of the products. The stand-alone vision inspection device detects non-conforming packages prior to packaging and rejects them, if there are product, package discrepancies or deviations. The staff are then immediately warned visually and audibly in order to be able to intervene and rectify the problem. Vision inspection system SealSecure prevents extensive and costly rework, eliminating claims and product recalls due to non-conforming packages. In addition, the Vision inspection system SealSecure ensures that only flawless products reach the market or end user. In addition, all the product images are saved in the production system and the relevant production reports are generated, the vision inspection system contributes to complete traceability of the production line. The Vision inspection system SealSecure...

Request for a quote

BIZERBA SE & CO. KG

Germany

The end-of-line X-ray inspection system offers maximum safety. By using X-ray technology the XRE-D detects contaminated, damaged and defective products and packagings. Besides metallic and non-metallic foreign objects it detects missing, defective or misshaped products as well as overweight or underweight. Thanks to an efficient quick conveyor belt change system the belt can be changed within two minutes. The product inspection system XRE-D X-ray inspection system detects all foreign objects, which due to their density, chemical components or mechanical dimensions absorb X-rays at a higher or lower degree than the surrounding product. During production numerous detection tasks can be safely fulfilled such as the detection of metals, glass, ceramics, stones, raw bones, PVC, Teflon, rubber, glass fibre reinforced plastics etc. In packaged or unpack-aged food (non-magnetic stainless steels and non-ferrous metals in aluminium packaged food). X-Ray inspection is an ideal solution for...

Request for a quote

BIZERBA SE & CO. KG

Germany

Quick and reliable detection of all ferrous and non-ferrous metals in packaged and unpackaged piece goods. The compact metal detection system offers you safe performance and highest detection sensitivity. With its robust stainless steel conveyor belt construction the VARICON+ inspects piece goods of up to 50 kg. A very short metal-free zone (MZ) ensures interference-resistant, reliable inline metal detection. To suit the area of installation the system is available with a modular belt (wet area) or a flat belt (dry area). The conveyor belts are available with variable belt widths. The motor controller is fitted either with a conveyor stop in case of metal detection or an application-specific rejection system. For easy and thorough cleaning the VARICON+ series has a hygienic design. Quality which is reflected in BRC, IFS and HACCP certifications. The VARICON+ comes with IP65 protection. Higher IP ratings are optionally available.

Request for a quote

JME LTD

United Kingdom

JME portable Betatron systems are a range of compact circular electron accelerators producing a high energy directional X-Ray beam. The Betatron systems are easy to assemble, operate and maintain. They contain no moving parts or cooling liquids so maintenance required on the systems is minimal. They are capable of producing radiographs of very high contrast, sensitivity and resolution allowing operators to meet the tightest inspection standard. JME offer 4 systems within the Betatron range each with a different maximum energy, the outputs are 2.5, 6, 7, 7.5 and 9MeV. The energy output on all systems is variable from 2Mev through to the maximum energy and adjustments can be made in 0.1MeV increments. The systems offer cost savings and a greater degree of portability when compared with systems such as linear accelerators (Linacs) which are much larger, non-portable, and can cost up to 10 times the price of a JME Betatron.

Request for a quote

DENGE ELEKTRONIK LTD ,,

Turkey

PG 6040 PLUS is a practical x-ray security equipment which has been widely applied for public security organs and its medium tunnel design is specially for scanning parcels, backpacks,hand luggage, cabin baggage and so on. PG 6040 PLUS has high mobility (and could be easily move to any locations which need the security inspection) through rolling casters. PG 6040 PLUS is an ideal model for baggage scanning because of its reasonable design and various image-processing functions.

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond DSV Sideshooter provides reliable detection of foreign objects in upright tall packaging. The compact, hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes.

Request for a quote

MINEBEA INTEC GMBH

Germany

The X-ray inspection system Dylight guarantees extremely high levels of safety for your packaged food. This true ‘Plug and Play’ solution combines all functions in one compact unit. Extremely compact design Plug and Play: All functions in one unit Takes up only one metre of space in your production line Complete with separator and run-off container Maximum product safety thanks to the highest degree of detection sensitivity Intuitive, time-saving operation Easy installation and integration into networks

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond Series of X-ray inspection systems is extremely versatile. Featuring 4 models it is able to cover the majority of applications for inspecting packaged products. With belt widths up to 800 mm it is ideal for multi-lane applications of up to 8 traces. Hygienic design, following EHEDG principles featuring sloped surfaces and curved edges allowing easy inspection and cleaning, resulting in considerable time and cost savings A wide range of standard possibilities for ensuring product integrity and quality including checking completeness, determining product mass and determining compartment mass Covering belt widths from 200 mm up to 800 mm 15" color touchscreen display Combining high detection sensitivity with low power consumption

Request for a quote

THOMSON MACHINERY BV

Netherlands

Eagle X-ray inspection system Pack 430 Pro (as new, only used as demo machine) for product dimensions max. 430mm wide, max. height 215mm Refurbished, new conveyor belt, new detector ! Technical data: Installation length:1.830mm Conveyor belt width:430mm Generator: HR 9 Feeding height:ca. 850mm Delivery height:ca. 850mm Dapu9dl Diodes:optional with 0,8mm or 1,2mm MDX diodes (DUAL ENERGY) Conveying speed with 0,8mm diodes:max. 1,10m/sec Conveying speed with 1,2mm diodes:max. 1,30m/sec Operating hours:approx. 800 Protection class:IP 65 Year of manufacture:2017

Request for a quote

QUELLTECH GMBH

Germany

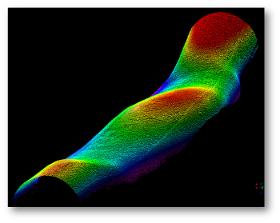

Particular Challenges: In the course of the production, endless cables are running at a considerable speed, and supervision has to be carried out nearly under real-time conditions. The size of the objects to be determined, i.e. of the flaws to be discovered, is in the range of only some hundredths of a mm. Another difficulty is the fact that surfaces with very different reflectivity and roughness are involved. In order to be able to check the cables all around, several laser scanners must be in place, mounted at different angles, thus covering the entire range of 360°. Quelltech Solution: The solution consists in a configuration of four Q6 laser scanners, mutually displaced by 90°, so the entire surface of the cables is in the field of view. On the basis of the 100% inline inspection, the position of defects can precisely be determined, without losing too much time.

Request for a quote

QUELLTECH GMBH

Germany

The new QuellTech Q5 Laser Scanner Series combines the advantages of small form factors with both high resolution and scan rate. The sensor disposes of different set-up possibilities with respect to the analysis algorithm. Measurement results are delivered via Ethernet, calibrated in the X / Z plane. Special adjustable algorithms can be selected, extremely useful particularly also for optically most demanding surfaces. Time-consuming calibration tasks for the user are no more required, as the calibration routine runs on board. High Scan Rate with up to 14,000 Profiles per Second Due to an appropriate limitation of the image range (AOI) in X and Z direction, the scan rate could considerably be increased. High resolution and detection frequency with up to 14.000 profiles and 28 Mio. points per second •X measuring range from 10 to 1022 mm •Z measuring range (height) from 5 to 878 mm •Laser wave length blue 405/450nm, red 650nm

Request for a quote

AKOMEX GROUP

Poland

LABELS PRODUCED ON PAPER OR FOIL LABELS PRODUCED ON A SILICONE OR FOIL BASE FLEXO TECHNOLOGY LINES FOR PRINTING AND ROLLING ROLLING MACHINES EQUIPPED WITH ELECTRONIC SYSTEMS FOR 100% IN-LINE PRINT INSPECTION SYSTEM

Request for a quote

BIZERBA SE & CO. KG

Germany

The robust metal detector can be variably used in dry and wet environments. It ensures best test results for packaged or unpackaged piece goods. VARICONcompact safely checks for any contaminants enclosed in the product such as steel, stainless steel and non-ferrous metal, e.g. aluminum. The compact metal detection system works with highest detection sensitivity. Ideally suitable for a save test performance. With its robust stainless steel conveyor belt construction the VARICONcompact inspects piece goods of up to 20 kg. A very short metal-free zone (MZ) ensures interference-resistant, reliable inline metal detection.

Request for a quote

BIZERBA SE & CO. KG

Germany

Metal detection coil INTUITY reliably detects enclosed contaminants in your product or bulk goods. INTUITY can be flexibly used in dry or wet areas and achieves best results with its multi-simultaneous frequency technology: It simultaneously checks with at least two frequencies if your packaged or unpackaged product contains steel, stainless steel, iron or non-ferrous metal. The metal detection coil helps you to enhance the quality of your products and to minimize the risk of possible recalls. INTUITY reliably checks if your packaged or unpackaged products or bulk goods include metal foreign objects. It is impressive in terms of its high accuracy: With its multi-simultaneous technology it checks at the same time with at least two frequencies within a range between 30 and 900 kHz

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Inspection Chamber TAR 250 to keep roof drainage outlets free with four connection options for TAR 80/250 or TAR 120/250.For pressure drainage and keeping drainage outlets free 4 possible connections for the drainage gutter TAR 80/250 or TAR 120/250 (preperforated openings) Chamber walls and lid with entry seals With aluminium chequered plate Walkable

Request for a quote

MICRO-EPSILON

Germany

For the production of reeled resistors or sheet goods on roller head installations the thickness measurement is an essential factor for controlling and monitoring the production process. Applying systems of the RTP series, the profile thickness can be measured in various accuracy classes, thickness ranges and material widths.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MICRO-EPSILON

Germany

The RTP 8301.CT is based on laser triangulation sensors and therefore ensures the measurement being independently from material constants. The system is designed as O-frame, both sensors detect the thickness according to the differential method. In order to ensure highest precision, the laser beams of the sensors are accurately adjusted during the production process using optoelectronic tools which have been specially developed. The system is ideal for monitoring high-dynamically processes due to its high measuring rate. The O-frame mechanics of the system dispose of a compensation frame which does not vary with temperature and which is used in order to avoid temperature fluctuations of the measuring frame using further sensors. The profilometer corresponds to the TIP 8301.CT regarding its functionality. However, it has a different operators´ frontend and evaluation functions.

Request for a quote

MICRO-EPSILON

Germany

The system RTP 8301.EO operates according to a combination principle consisting of a thru-beam sensor, an eddy current sensor and a measuring roller. The eddy current sensor and the thru-beam sensor are applied on an innovative measuring clamp. Since the sensor measures the distance from the clamp to the roller, the lower side of the material is detected. As the sensor performance is specially aligned with the measuring task a huge measuring gap is possible while offering highest precision. The thru-beam sensor detects the upper side of the material. The thickness of the target is the difference between the two signals. The measuring clamp is equipped with a pneumatically cleaning mechanism and therefore ideal for the application in harsh environment. The profilometer corresponds to the TIP 8301 regarding its functionality. However, it has a different operators´ frontend and evaluation functions.

Request for a quote

MICRO-EPSILON

Germany

For the production of reeled resistors or sheet goods in calenders the thickness measurement is a vital factor for controlling and monitoring the production process. By applying systems of the RTP series, the profile thickness can be measured in various accuracy classes, thickness ranges and material widths.

Request for a quote

MICRO-EPSILON

Germany

The idiamCONTROL sensor system precisely measures the inner diameter of bore holes such as in extruders in order to determine the wear. The idiamCONTROL is guided into the bore hole and determines the bore hole diameter while being pulled out. Wear-based tolerance violations are automatically displayed and can be output via USB.

Request for a quote

MICRO-EPSILON

Germany

The FTS 8102.EC C-frame is based on the combisensor principle equipped with non-contact capacitive sensors. The distance between sensor and film is measured with the capacitive sensor. The eddy-current sensors ensures the thickness signal by a reference measurement to a second target. The system is designed as a C-frame and can be used as a traversing unit by using the linear axis.

Request for a quote

MICRO-EPSILON

Germany

The BTS 8101.EO O-frame is based on the combisensor principle. The system is equipped with a non-contact capacitive sensors and a Thrubeam sensor which are integrated in a traversing frame. The eddy current sensor measures the reference distance to the measurement roll‘s metal surface. The distance from the film surface is measured by the Thrubeam sensor. Together with the reference signal the film thickness is calculated. This combisensor principle allows extreme precise measurements.

Request for a quote

MICRO-EPSILON

Germany

The FTS 8101.EC O-frame is based on the combisensor principle equipped with non-contact capacitive sensors. The distance between sensor and film is measured with the capacitive sensor. The eddy-current sensors ensures the thickness signal by a reference measurement to a second target. The system can be integrated in the flat layer section.

Request for a quote

MICRO-EPSILON

Germany

The systems of the FTS familiy offer thickness measurements with extreme stability and accuracy. Applying them in extrusion lines provides reliable measurement results in high precision and thus creates the basis for controlling the production process and eventually the quality achieved.

Request for a quote

MICRO-EPSILON

Germany

The systems of the FTS familiy series offer thickness measurements with extreme stability and accuracy. Applying them in thermoformed flat film lines provides reliable measurement results in high precision and thus creates the basis for controlling the production process and eventually the quality achieved.

Request for a quote

MICRO-EPSILON

Germany

The systems of the FTS familiy series offer thickness measurements with extreme stability and accuracy. Applying them in extrusion lines provides reliable measurement results in high precision and thus creates the basis for controlling the production process and eventually the quality achieved.

Request for a quote

MICRO-EPSILON

Germany

Gauges and inspection systems from Micro-Epsilon are used in the plastics processing industry in order to ensure efficient production.

Request for a quote

MICRO-EPSILON

Germany

The demand for aluminum is constantly increasing due to its special technical properties. It can be made thinner and thinner as the strength increases. This is accompanied by tight manufacturing tolerances, which require measurement technology with more precision. As a manufacturer of measuring systems for the aluminum industry, Micro-Epsilon offers a comprehensive portfolio based on optical sensors without radioactivity that ensures More Precision in applications regardless of complexity and material properties. Optimized sensor technology tailored to the respective application, innovative mechanical design, as well as cooling and protection devices enable the systems to meet the needs of the processes. The high-performance signal processing and analysis software makes the systems the leading optical gauges on the market which detect the following parameters

Request for a quoteResults for

Inspection systems - Import exportNumber of results

128 ProductsCountries

Category

- Sensors (33)

- Surface inspection systems (20)

- Metal detectors (10)

- Measurement - Equipment & Instruments (8)

- Machine vision system (7)

- Harvesting machinery and equipment (6)

- Production and operational inspection (5)

- Automation - systems and equipment (4)

- Monitoring and control equipment (4)

- Monitors, computer (4)

- Handling - Machines & Equipment (3)

- Safety equipment, work (3)

- Electronic components (2)

- Optical measuring equipment (2)

- Security and surveillance - electronic displays (2)

- Chemicals and pharmaceuticals - packaging machinery (1)

- Customer relations management software CRM (1)

- Drainage systems and equipment (1)

- Electronic cards (1)

- Engine testing and regulating equipment - electronic (1)