- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- induction coils

Results for

Induction coils - Import export

ENERCON INDUSTRIES LTD

United Kingdom

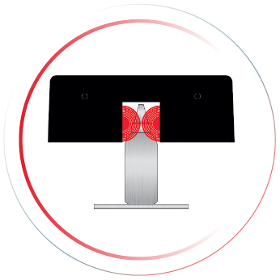

Enercon has two coil design types, each with several variations, to ensure the perfect coil is available for the size and type of your container and cap for your application to deliver perfect, consistent seals. Tunnel coils facilitate higher throughputs than the more traditional flat coils. The Deep Tunnel Coil is used for conical, spouted and other shaped caps. The All-in-One Coil is a variation of the Flat Coil. It is available with the Super Seal™ range and Super Seal™ Touch. This flat sealing head can be pivoted to accommodate various applications. Capable of sealing containers with cap diameters ranging from 20mm to 140mm, it is ideal for packagers who seal a variety of containers and offer the highest degree of sealing versatility. Packagers often don’t realise that the efficiency of the sealing operation depends on the design of the sealing head.

Request for a quote

HOMESHOP

Poland

A wireless charger in a compact size will allow you to monitor the battery status and ensure that your electronic device is always ready to work. A 2-in-1 gadget equipped with two induction coils, so its functionality automatically increases.

Request for a quote

HOMESHOP

Poland

This Baseus charger is equipped with two independent induction coils. The high power of 15W allows for effective battery charging in the most popular devices, especially smartphones. It saves a lot of time when you can simultaneously charge a smartphone with a power of 15W or a smartphone and headphones (15W + 5W) or two smartphones (10W + 10W).

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

The induction generator is designed to supply up to 4 induction coils (inductors) with a power of up to 7.5 kW each. The device operates on the three-phase mains with a voltage of up to 400 V and a frequency of 50/60 Hz. The mains current is rectified and fed to the DC link, from which the inductors are individually supplied.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

The induction generator module is designed to supply up to 6 induction coils (inductors) with a power of up to 3 kW each. The device operates on the three-phase mains with a voltage of up to 400 V and a frequency of 50/60 Hz. The mains current is rectified and fed to the DC link, from which the inductors are individually supplied. The output power is controlled via the Kendrion controller of the modular industrial heating system. The setting range from 0% to 100% can be selected individually for each channel. By using state-of-the-art semiconductor switches, the output stages achieve high efficiencies, at working frequencies up to 25 kHz.

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

Many of the issues causing poor seals happen upstream, in the filling or capping area: a seal cannot be achieved with a missing cap or a cap with a missing foil. The capper can also cause stalled bottles under the induction coil where caps are loose or partially fitted or the cap is incorrectly fitted or too high. Issues downstream from the sealer can cause containers to back- up under the sealing head. Enercon produces a range of sensors to help ensure that the sealing process is running faultlessly, producing consistent, reliable seals on every container. • Stalled Bottle and Backlog Detector • Missing Foil Sensor • High Cap Detector • Stack light assembly • Variable Speed Conveyor Systems • Spare Parts Kit • IQ/OQ Kit

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

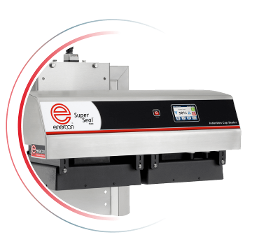

The Super Seal™ Max is the fastest inline sealer on the market, with a dual coil it’s designed for high-speed packaging lines running at up to 100 metres per minute. This dual coil air-cooled induction cap sealer offers increased power and a multi-language touch screen for a simpler operation. It delivers reliable sealing with a diverse operating window that compensates for cap, liner and container tolerance variations. • Multiple language selection • Easy to use touch screen • Supervisory password protection with operator lockout • Recipe management • Internal monitoring of all critical operating data • Container, cap and foil counters available • Local and remote start/stop and power control • Stainless steel IP55 enclosure • Remote network control and monitoring via RS485 or Ethernet • Robust stainless steel fully adjustable stand for different container heights • Seals a variety of caps ranging from 20mm – 150mm • Fully compliant with all CE regulations

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

This single coil induction cap sealer offers users increased productivity, an easier set-up and more control. The easy-to-use touch screen is available in multiple languages. The Super Seal™ Touch is our most powerful compact single-coil machine and is designed for production lines running at up to 40 metres per minute. The air-cooled power pack is separate from the induction sealing coil. • Pre-programmed and fully integrated touch screen control for inspection and rejection • Remote start/stop and remote power control (auto start function available) • Password protection with operator lockout • High and low level set power alarm • Recipe management • Internal monitoring of all critical operating data • Diagnostic system information • Internal USB data port – Network connectivity available • Stainless steel IP55 enclosure • Robust stainless steel fully adjustable stand for different container heights • Seals a variety of caps ranging from 20mm – 150mm

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

Available in three models Super Seal™ 300 Super Seal™ 400 Super Seal™ 600 We have built on the proven design of the Super Seal™ range of induction cap sealers, to bring new features to give more value to packagers. The new Super Seal™ compact induction cap sealers are available in three power levels. There are a variety of sealing heads available to optimise sealing performance for your specific applications. •New display simplifies setup, operation & troubleshooting •Local/Remote modes for start/stop & power level •Seals a variety of caps ranging from 20 – 150m •System settings in a single level menu •High efficiency plug-in induction sealing coils to maximise performance and minimise energy costs •Compact and air-cooled •Power supply electronics are housed in an IP55 enclosure •Fully compliant with all UK and European regulations •Fully adjustable stainless-steel stand for different container heights

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

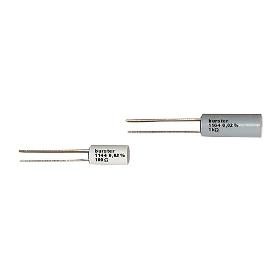

Precision resistors are used wherever the highest standards of temperature stability, error tolerance and durability are required. Models 1164 and 1166 are available for higher loads up to 1 W. The resistors are supplied with two connections on the front end (suitable for mounting on circuit boards). The precision resistors comprise low-capacitance, low-inductance wire coils made of MANGANIN®, which are encapsulated in small plastic cylinder housings. Prior to trimming, the resistance bodies are exposed to a meticulous artificial aging procedure. This special process and trimming to approximately half of the nominal tolerance guarantee long-term stability of < 0.02% over the course of years. FEATURES: — TC ≤ 10 ppm/K —Class ± 0.02 % or ± 0.05 % —Production range from 5 Ω ... 100 kΩ —Resistance material MANGANIN® —Custom resistance values available on request —Minimum order per resistance value 10 pcs

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Inductive displacement sensors of this series measure linear displacements and indirectly all mechanical values convertible into displacements by additional equipment (i.e. tension and compression forces, extension, torque, vibration). The sensor body equipped with a connector has an outer diameter of only 8 mm and therefore is especially well suitable for the integration in dimensionally restricted structures. Typical application fields are displacement and extension measurements on: —Machines —Servo systems —Motor vehicles —Test benches —Production plants The cylindrical case made of stainless steel, houses a differential transformer (LVDT). It consists of a primary and two secondary coils with axially moveable core. A displacement of this core changes the magnetic induction of the coils. The INLINE carrier frequency amplifier converts the displacement into a direct proportional electrical DC voltage.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

An alternative to conductive heat sealing is contact induction sealing, which is particularly suitable for sealing demanding container materials such as e.g. glass, metal or ceramic. An electromagnetic field is built up by a generator via an induction coil that is housed in the sealing head. The molecules of the aluminum foil are set in rotating vibrations, creating heat that is used for the sealing process. Our sealing machines PolySeal Vario PN and PolySeal Vario Twin as well as all fully automatic sealing systems can be equipped with induction technology.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers work according to the principle of the differential choke (inductive half bridges). They consist of two coils which are encapsulated in a Mu metal cylinder in a sealed and vibration-proof manner. A Mu-metal plunger causes an opposite induction change in the two coils when displaced by the hollow coil body. The displacement transducers are designed for an oscillator frequency of 10 kHz. Power supply and signal conditioning are provided by external module modules.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers work according to the principle of the differential choke (inductive half bridges). They consist of two coils which are encapsulated in a Mu metal cylinder in a sealed and vibration-proof manner. A Mu-metal plunger causes an opposite induction change in the two coils when displaced by the hollow coil body. The displacement transducers are designed for an oscillator frequency of 10 kHz. Power supply and signal conditioning are provided by external module modules.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers work according to the principle of the differential choke (inductive half bridges). They consist of two coils which are encapsulated in a Mu metal cylinder in a sealed and vibration-proof manner. A Mu-metal plunger causes an opposite induction change in the two coils when displaced by the hollow coil body. The displacement transducers are designed for an oscillator frequency of 10 kHz. Power supply and signal conditioning are provided by external module modules.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The linear transducers operate according to the differential throttle principle (inductive half-bridges). They consist of two coils which are impermeably cast into a Mu-metal cylinder, where they are protected from vibrations. On displacement through the hollow coil body, a Mu-metal plunger leads to a change in the induction direction in both coils. The linear transducers are designed for an oscillator frequency of 10 kHz. The supply and signal processing are carried out by external modules.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers work according to the principle of the differential choke (inductive half bridges). They consist of two coils which are encapsulated in a Mu metal cylinder in a sealed and vibration-proof manner. A Mu-metal plunger causes an opposite induction change in the two coils when displaced by the hollow coil body. The displacement transducers are designed for an oscillator frequency of 10 kHz. Power supply and signal conditioning are provided by external module modules.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers work according to the principle of the differential choke (inductive half bridges). They consist of two coils which are encapsulated in a Mu metal cylinder in a sealed and vibration-proof manner. A Mu-metal plunger causes an opposite induction change in the two coils when displaced by the hollow coil body. The displacement transducers are designed for an oscillator frequency of 10 kHz. Power supply and signal conditioning are provided by external module modules.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

eldec brazing systems: automatic induction brazing of pole coils The semi-automatic equipment is designed for manufacturing pole coils of hydro and wind power generators. The machine is based on the experience of the previous manufactured equipments. The machine is designed as a sturdy, high quality and low maintenance machine. The operating is very simple, on automatic mode by 2-hand operation with step by step program and on manual mode by touch-panel.

Request for a quote

KUK COILS SLOVAKIA S.R.O.

Slovakia

Unlike air coils, bobbin coils, as the name already suggests, have a ferromagnetic body or coil former made of different material. The advantage of solenoid bobbin coils: higher inductances can be generated. Whether complicated to manufacture or adapted to special requirements - thanks to in-house winding lines, KUK produces the right bobbin coil for you. The bobbin coils are partly manufactured on standard coil formers. However, we mainly wind onto customer-specific coil formers. We wind bobbin coils from enamelled copper wire or alternative conductor material and thus achieve optimum results in customer-specific applications. We will be happy to advise you on the optimum core material for your solenoid bobbin coil. You can also benefit from our many years of cooperation with specialised suppliers. -Different winding methods -With pin mounting -Connection of litz wires, plugs, etc. -Twisted wire ends

Request for a quote

KUK COILS SLOVAKIA S.R.O.

Slovakia

KUK manufactures air coils for a wide variety of applications, e.g. RFID antennas, control coils or transponder coils. To produce self-supporting coils, self-bonding wire is also used, which is superficially bonded (glued) together during or after winding. Air coils are usually made of enamelled copper wire or high-frequency litz wire. So-called self-bonding wire is used to manufacture self-supporting air coils. It has an outer layer whose melting point is lower than the melting point of the insulation. After winding the air core coil, the turns of the coil are "baked" (glued) together by heating, usually by increased current flow. Thanks to our in-house plant engineering, we can optimally align our production lines to your needs, even for air core coils. - Ultra-fine wires starting at 0.020 mm - Single-layer flat coils in cylindrical or rectangular shape - single, bifilar or trifilar winding - Winding with HF litz wires

Request for a quoteResults for

Induction coils - Import exportNumber of results

22 ProductsCountries

Company type