- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hot machines

Results for

Hot machines - Import export

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Process: In feed bottle → pre-position →label cutting → gluing → labeling → label by press out → finish Hot melt OPP glue labeling machine is widely used for different material of container . The label cost is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is the most economical models in cost to make mass production and intergrated operating. The equipment has massively used modularization design concept to make it easy and simple for users to change the bottles. Whether from the replacement of star wheel, guide plate or manual speed adjustment to automatic speed control, for example changing the label is only needed to change the program, the products concept of that the equipment is designed for users is embodied in everywhere.

Request for a quote

THOMSON MACHINERY BV

Netherlands

swissQprint Impala LED – 2m x 2.5m LED Flatbed Printer.

Request for a quote

MAROVT D.O.O.

Slovenia

Precision forged parts are forged parts where very narrow tolerance can be achieved by following the forging process permanently. Our processes enable forging with the +/- 0.1mm tolerance. We are specialized in the production of precision forged parts weighing between 0.001kg and 1kg made of different material. The advantage of precision forged parts is that they can be used mostly in different compounds and without additional mechanical machining. Hot die drop forging is the method in our company – sticks are heated and inserted into the appropriate forging tool.After the forging process, we trim and pierce the semi-finished products to meet many shapes and other requirements. We shape stainless, alloy and carbon steels. In most cases, more complex and larger forgings are further machined.Due to the specificity of precision forgings, we provide the minimum necessary additional machining and thus reduce the machining times.

Request for a quote

FERPLAST SNC

Italy

Sealing machine with stand and mechanical footswitch, constant heat sealing bars fot the closure of polypropylene bags and coupled in aluminum, paper, barrier materials, etc. The sealing bars of the type "hot bar" are equipped with resistance and temperature controller for controlling the temperature from 30 ° C to 200 ° C. The closing of the sealing bars by a mechanical pedal guarantees a high welding pressure and allows the sealing of high thickness envelopes with or without lateral bellows.

Request for a quote

FERPLAST SNC

Italy

TABLE MONOBLOC SEALER WITH MANUALLY OPERATED SEALING BAR AN INCORPORATED ROLL HOLDER The SP 600 is equipped with sealing bar with NI-CR wire for simultaneous cutting and welding of the film. Allows to obtain a polyethylene or polypropylene bag, perfectly welded and trimmed, using the normal fold film. Suitable for use in laundries, shirt factories, the textile sector in general, but is also suitable for the food sector for the packaging of the bread. Operation: Place the coil with the open side facing the operator Insert the open-film blade between the two flaps Unroll the film to the desired length Lower the sealing bar and cut the bag Enter the product in the bag and make the welding of the side remained open.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

age 1993 semi automatic hot stamping machine stamping area max. 125 x 280 mm electr. drive 1 foil feeder 1 heating plate automatic feeding unwinding system for round material / cans underframe Delivery time: immediately from stock Ref: GI200261A Please ask for price. We ship and install worldwide!

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Hot forging and CNC machining Brass parts

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of rolling and friction bearings at operating temperatures around +170°C up to rotating speed limit For example, smaller bearings of exhaust-gas turbochargers, hot-air fans, hot-water pumps, washing machines and laundry dryers, as well as clutch pressure and release bearings etc. Also suitable for plastic/plastic sliding pairs Advantages and benefits Highly effective due to optimum temperature-stable silicone grease formula Excellently suited for grease lubricating points subject to changing temperature loads Broad range of uses outside normal grease performance areas

Request for a quote

DEKORTECH GMBH

Germany

Digitally printed heat transfers for beauty and cosmetic packaging - printed roll to roll. ✔ No MOQ ✔ up to 318mm printing width ✔ Easy to apply ✔ High gloss finish ✔ Photo-realistic prints ✔ Fastest shipping Digital heat transfers are the easiest way to get into digital printing for your products. Therefore, we print them on demand with any design you need. Make use of this product for your beauty and cosmetic primary packaging. From cosmetic tubes to airless dispensers or mascara bottles. Printed in less than 5 days, you will be ready to roll in no time. For the printing itself we use a high-end digital printing press based on toner and combine it with water-based adhesives without UV or VOCs. With this mix we can print details as tiny as 1-point small text. Personalized or serialized prints with safety features are also available. All you need to apply them is a heat transfer or hot stamping machine.

Request for a quote

DEKORTECH GMBH

Germany

Digitally printed heat transfers for pens & pencils - printed roll to roll. ✔ No MOQ ✔ For all materials ✔ Easy to apply ✔ High gloss finish ✔ Photo-realistic prints ✔ Fastest shipping Digital heat transfers are the easiest way to get into digital printing for your products. Therefore, we print them on demand with any design you need. These transfers are made to adhere to a range of pens and pencils. From plain wood to coated pencils up to PP and ABS pen barrels. Printed in less than 5 days, you will be ready to roll in no time. For the printing itself we use a high-end digital printing press based on toner and combine it with water-based adhesives without UV or VOCs. With this mix we can print details as tiny as 1-point small text. Personalized or serialized prints with safety features are also available. All you need to apply them is a heat transfer or hot stamping machine.

Request for a quote

DEKORTECH GMBH

Germany

Digitally printed heat transfers for PP plastics - printed roll to roll. ✔ No MOQ ✔ up to 318mm printing width ✔ Adhere to untreated Polypropylene ✔ High gloss finish ✔ Photo-realistic prints ✔ Fastest shipping Digital heat transfers are the easiest way to get into digital printing for your products. Therefore, we print them on demand with any design you need. These unique transfers are finished to adhere to untreated PP plastics and make them easy to use for cosmetics, promotional products, and other applications. Printed in less than 5 days, you will be ready to roll in no time. For the printing itself we use a high-end digital printing press based on toner and combine it with water-based adhesives without UV or VOCs. With this mix we can print details as tiny as 1-point small text. Personalized or serialized prints with safety features are also available. All you need to apply them is a heat transfer or hot stamping machine.

Request for a quote

DEKORTECH GMBH

Germany

Digitally printed heat transfers for packaging applications - printed roll to roll. ✔ No MOQ ✔ up to 318mm printing width ✔ Adhere to many materials ✔ High gloss finish ✔ Photo-realistic prints ✔ Fastest shipping Digital heat transfers are the easiest way to get into digital printing for your products. Therefore, we print them on demand with any design you need. With a range of adhesives, these transfers can be produced to stick to PP, ABS, paper, glass, ceramics, varnishes, Tritan and many other materials. Printed in less than 5 days, you will be ready to roll in no time. For the printing itself we use a high-end digital printing press based on toner and combine it with water-based adhesives without UV or VOCs. With this mix we can print details as tiny as 1-point small text. Personalized or serialized prints with safety features are also available. All you need to apply them is a heat transfer or hot stamping machine.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

In order to get started with low pressure molding technology, for prototyping new projects and producing small series, Labline offers a selection of small devices tailored to the requirements of low pressure molding technology. The basis here is the hand-held casting gun with a 0.2l tank for filling the casting materials in granulate form. In order to achieve process stability and reproducibility even with this manual processing, a timer can be connected. Two different clamping devices are available for convenient handling of sample and pre-series tools. product [hot melt application systems, hot melt coating machines for paper, hot melt, hot melt adhesive, hot melt adhesives, special machines for adhesive processing, hot melt packaging, machine for gluing, machines for gluing, hot melts, gluing machines, hot melt coating, gluing machines for labels, laboratory coating machines, systems for adhesive technology]

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

The CUSTOMline hot melt machine is the top solution for customized casting requirements. It is configured specifically according to customer requirements and can handle complex casting tasks with exceptional precision and efficiency. This machine is ideal for special applications where standard solutions are not sufficient. With the CUSTOMline you get a casting machine that is tailored precisely to the specific needs of your production process in order to achieve optimal results. product [hot melt application systems, hot melt coating machines for paper, hot melt, hot melt adhesives, hot melt packaging, hot melt adhesives, special machines for adhesive processing, hot melts, machines for gluing, machine for gluing, melt casting technology with hot melt, hot melt coating, gluing machines, special machines for casting, sealing, foaming, gluing, special packaging machines]

Request for a quote

OKSUZOGULLARI HORECA VE EV GERECLERI A.S

Turkey

SC05 Salep is a 5 liter capacity countertop hot beverage dispenser that keeps hot chocolate, tea, coffee, milk and similar hot beverages warm with the "BAIN-MARIE" method, mixes and distributes them homogeneously and without lumps. Thanks to the specially designed “BAIN-MARIE” heating system, hot drinks do not condense and do not stick to the bottom of the chamber. All metal parts of our hot drink machine are made of high quality stainless steel. Thanks to the continuous rotation of the mixing palette, the fluid consistency is maintained and no lumps are formed. The water level of the “BAIN-MARIE” system can be observed from outside the hull. Thanks to the closed-circuit "BAIN-MARIE" water heating system, there is no loss of water vapor, the water level is maintained for a long time, thus preventing calcification of the resistance. If our Hot Beverage Machine operates without water, the warning light on the outside of the body will turn on, indicating that water needs to be added to th

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg have a freind factory which specialize in Hot forging services, we can outsourcing the rough parts from hot forged parts, then machining it to final parts.Can effectively reduce the production cost and improve the production speed, as well as product quality. The hot forging process can produce steel products of all sizes and shapes,the forged parts have higher density and strength and are suitable for the production of various valve and pipe fittings,such as flanges, rings... We can forge stainless steel 304,316, brass, aluminum alloy, carbon steel, alloy steel and other materials. If you have any parts suit for hot forging process, welcome contact with us to check it.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg have a freind factory which specialize in Hot forging services, we can outsourcing the rough parts from hot forged parts, then machining it to final parts.Can effectively reduce the production cost and improve the production speed, as well as product quality. The hot forging process can produce steel products of all sizes and shapes,the forged parts have higher density and strength and are suitable for the production of various valve and pipe fittings,such as flanges, rings... We can forge stainless steel 304,316, brass, aluminum alloy, carbon steel, alloy steel and other materials. If you have any parts suit for hot forging process, welcome contact with us to check it.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MING XIAO MANUFACTURING CO., LTD

China

Stainless Steel Assembly Parts shows in pictures are made from SS304, Customer from Italy. It's made from hot forged rough parts,then machined to the final parts, machining processes are CNC turning and Milling. Ming Xiao Mfg engaged in Turning Parts custom machining services more than 20 years, we have old lathe turning machines, automatic turning machines, and CNC turning machines,Longitudinal lathes (CNC PRECISION AUTOMATIC LATHE). we can optimize the turning processes to make the machining cost to be lowest, for high precison turned parts or with a certian accuracy required turned parts that we use CNC Lathe to produce, and low tolerance requested dimensions we use old lathe machine to produce, and small turned parts we use automatic lathe machine to produce. Materials: Carbon Steels,Alloy steels,Tool Steels,Stainless Steels,Aluminum Alloys,Brass & Copper. Finish treating: Anodizing,hard anodizing,electroplating

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Stainless Steel Parts shows in pictures are made from SS304, Customer from America. It's made from hot forged rough parts,then machined to the final parts, machining processes are CNC turning and Milling. Ming Xiao Mfg engaged in Turning Parts custom machining services more than 20 years, we have old lathe turning machines, automatic turning machines, and CNC turning machines,Longitudinal lathes (CNC PRECISION AUTOMATIC LATHE). we can optimize the turning processes to make the machining cost to be lowest, for high precison turned parts or with a certian accuracy required turned parts that we use CNC Lathe to produce, and low tolerance requested dimensions we use old lathe machine to produce, and small turned parts we use automatic lathe machine to produce. Materials: Carbon Steels,Alloy steels,Tool Steels,Stainless Steels,Aluminum Alloys,Brass & Copper. Finish treating: Anodizing,hard anodizing,electroplating

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Technical : Aluminium Hot Forging + Precision Machining Product Name : Aluminum Fastener Main Use : Auto Parts Technical parameter Technical Aluminum Hot Forging Fastener + Precision Machining Material: Al-6061 T6 Al-6063 Material Standard GB,ASTM,AISI,DIN,BS,JIS,NF Forging Weight 0.3kg~5kg Forging Dimension Tolerancez: CT8-10Grade Forging Surface Rough: Ra6.4 – 3.2 Rough of Machining Surface:Ra0.8-1.6 Support File of Format: ProE (.igs , .stp) , Auto CAD , PDF, Jpeg, Jpg, Png Heat Treatment: Quenching and Tempering , High Frequency Quenching Machining Equipment CNC Center,CNCs, Drilling Machine. Surface Finished Hard Anodizing Measure Tool: Micrometer, Caliper, Height Gauge,Screw Gauge Inspection First Checking , Checking , Final Checking QC Report:Material Report, Product Ddimension Inspection Report.

Request for a quote

TECHNIC MACHINES

Turkey

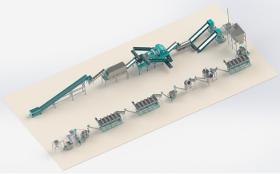

Our PET bottle recycle machine line is designed to give great recycling solution for PET bottle recycle process. We provide different solutions according to our customers PET bottle recycle machine demand, such as different capacity, dirtiness level, hot washing or cold washing system or etc. So we design our PET bottle recycle machine according to our customer's market requirements. Our PET bottle washing line can be designed for high level dirty PET bottles, with or without bales, Hot-Wash or Cold-Wash and etc. PET Bottles Recylce Machine Line Main Units, – Conveyor – Bale Opening Machine – Helezon – Cap and Label Remover – Sorting Belt – Drum Tromel – Conveyor Belt – Crusher Machine – Screw Loaders – Hot Washing Unit – Friction Washer – Flotation Tanks – Drying Units – Big Bag Filling Unit Just contact with us for your PET bottle recycling machine research, we will provide the optimum solution.

Request for a quote

FORMEX MAQUINARIA

Spain

PRODUCT •The filler is injected hot. MACHINE CHARACTERISTICS: •Machine for filling chocolate and/or jam into elongated buns. •The injection head has 8 nozzles. The needles are placed horizontally, they prick the buns and the product is injected at the same time as they are being withdrawn, thus achieving a uniform injection along the whole length of the bun. •The quantity and speed of injection are configured on the screen, allowing a more precise adjustment. •The tank is heated to keep the product warm and facilitate injection. •The conveyor has guides that facilitate the manual placement of the buns for greater operator comfort. •At the end of the belt there is an ejector so that it is much easier to remove the product. ADVANTAGES •Speed and increased production. •Uniformity in the quantity of doses injected and in the distribution of the filling. •Easy cleaning.

Request for a quote

FORMEX MAQUINARIA

Spain

PRODUCT: -Panettone 18cm in diameter and 22cm high. -The dulce de leche is injected hot. CHARACTERISTICS OF THE MACHINE: -Injector adapted to the dimensions of the product with precise injection regulation. -The whole injector block, including the tank, nozzles and needles, is located inside a heated tank that keeps the product at a constant temperature of 40ºC. -Smooth belt conveyor with markings to place the panettones by hand and a scraper at the end to clean any remaining dough. -The machine injects four panettones at the same time and the injection is driven by a servomotor. ADVANTAGES: -Ease of use. The operator places the panettones on the marked belt and collects them at the end of the process. -Quick and easy cleaning thanks to the scraper and the removable head for complete cleaning and disinfection. -Safety in the working process. -Production increase: 400% depending on working conditions and parameters.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

1.Part material: stainless steel 2.Machining type: precision cnc turning 3.Surface:Polishing ,Ra0.8 4.Tolerance:+/-0.02mm 5.Application : Machine parts 6.Quality,reliability and long product life.

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

- Standard perforation devices as module system at reasonable prices with manual or automatic roller adjustment - Perforating devices adapted to your machine and its special conditions - Perforation systems with driven rollers - Hot perforating systems for foils and nonwovens.

Request for a quote

CARTALOTO

France

HOT-DOG MACHINE 4 SPIKES - Glass cylinder - 4 skipes for bread,

Request for a quote

DOREY

France

The new Miller Weldmaster T300 Extreme combines heat, speed, pressure and precision with precise positioning of the weld head for increased efficiency and speed with an ergonomic design. With 4 positions and 3 arms integrated into one machine, you have the versatility to make almost any product. Larger, rotating/tilting, easy to use screen Available in hot air, hot iron, or both for greater product versatility Precision sealing head with three synchronized controls for increased efficiency and higher speeds. Test mode allows the operator to quickly find the optimal heat and speed setting for the machine. Adhesive tape dispenser included to easily apply Velcro weld and extruded profiles to any product. Built-in material extractor to reduce labor or long weld seams.

Request for a quote

ESTECHTIC EPS-EPP PROCESSING SOLUTIONS

Turkey

We can supply various types of EPS-XPS foam decoration machines - 2D/3D CNC cutting machines, thermopress or hot press machines, CNC routers, mortar mixing and coating machines and panel printers. For more information about our products and services, please visit www.estechtic.net. You can send your inquiries to fr@estechtic.net.

Request for a quote

TURKIYE MACHINES BAKERY MACHINES

Turkey

This machine is designed with a rotating cone and adjustable spiral shaped corrosion resistant tracks around it. The dough becomes perfectly rounded while moving from bottom to top in the tracks which are adjustable. The machine is also equipped with a newly designed mechanical flour duster which does not make any noise while working. The standard rounding track is 4.5 meters. The weight range is from 100 gr. To 600 gr. Electric power 0.55 kw 220/380 V AC.50 Hz. It is also possible to produce 50 gr. To 200 gr. working capacity rounder machine. rounding track is 4.5 meters. The weight range is from 100 gr. To 600 gr. Electric power 0.55 kw 220/380 V AC.50 Hz. It is also possible to produce 50 gr. To 200 gr. working capacity rounder machine. Option Hot and cold air blowing system / Teflon coated channels or conic body / Electronic speed control

Request for a quoteResults for

Hot machines - Import exportNumber of results

79 ProductsCountries

Company type

Category

- Cutting, plastics - machinery (5)

- Silk-screen printing (4)

- Textiles - Machines & Equipment (4)

- Chemical industry - machinery and equipment (3)

- Machine tools, metal machining - parts and accessories (3)

- Metallurgy - machinery and installations (3)

- Resins (3)

- Automation - systems and equipment (2)

- Flexography - machines (2)

- Lubricants, industrial (2)

- Package sealing machinery (2)

- Packing and packaging - machinery and equipment (2)

- Paint mixers and grinding machines (2)

- Potting equipment (2)

- Agricultural systems and equipment (1)

- Bakery - machinery and equipment (1)

- Bakery - machinery and equipment (1)

- Bakery and confectionery industry - machinery and equipment (1)

- Beverages - concentrates and powders (1)

- Bronzing - steel and metals (1)