- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat recovery

Results for

Heat recovery - Import export

ANTHERMO GMBH

Germany

Air-water / air-air heat exchanger as smooth tube heat exchanger up to 1,000 ° C Smooth tube heat exchanger as an air / water heat exchanger In the case of air-water heat exchangers (also called gas-water heat exchangers), a temperature exchange takes place between a gas (usually air) and a liquid. As a rule, the liquid medium flows inside the pipes, while the gaseous medium flows around the pipes outside the pipes. Smooth tube heat exchangers can cover various areas of application: heating, cooling and condensing as well as heat recovery. Smooth tube heat exchanger as air-to-air heat exchanger Smooth tube heat exchangers are also often used as air-to-air heat exchangers. In this application, a gas (e.g. exhaust air or exhaust gases) flows inside the pipes and a gas (e.g. fresh air) outside the pipes around the pipes.

Request for a quote

ANTHERMO GMBH

Germany

Temperature exchange between a gas and a liquid In the case of air-water heat exchangers (also called gas-water heat exchangers), there is a temperature exchange between a gas (usually air) and a liquid. Finned heat exchangers can cover various areas of application: - heating and evaporating, - cooling and condensing as well as heat recovery. In this context, lamellar heat exchangers are also called air heaters or air coolers. Air-water heat exchangers are often also used as exhaust gas heat exchangers or flue gas heat exchangers in order to recover the energy from warm or hot exhaust gases. Lamella packs for a large exchange area In order to achieve the largest possible exchange surface between the air and the medium (liquid) within the heat exchanger, lamellas or lamella packs are attached to the pipe system.

Request for a quote

ANTHERMO GMBH

Germany

Temperation of fluids Pillow plates are used everywhere where liquids must be temperated. In dependence of application the liquids can be cooled or heated. Cause of this wide range of applications pillow plates are used in the process industry, in the cooling industry and in a lot of other industries. Pillow plates are also know as heat exchanger plates, evaporator plates, cooling plates /sheets and thermo plates / sheets. Pillow plates as air-/water-heat exchanger Additionally to the temperation of liquids pillow plates are also used as air-/liquid heat exchangers. In case of polluted or wasted air and if there are high demands for cleaning, more and more pillow plates are used as air-/water-heat exchanger. The large exchange surface and the good possibilities for cleaning are important features for this type of heat exchanger.

Request for a quote

ANTHERMO GMBH

Germany

Air heat exchangers as finned tube heat exchangers Heat transfer between a gaseous media and a liquid Finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air) and a liquid (for ex. water) takes place in the air-/water heat exchangers. To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. Very often air-/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube heat exchangers can also be used as air heater, air cooler or condenser.

Request for a quote

ANTHERMO GMBH

Germany

Heat recovery with the help of heat exchangers In industry, waste heat occurs at many points in the production process, which is often released into the environment without being used. In many cases, energy is even used to cool the waste heat flows from production so that they can be released into the environment. Heat exchangers (also called heat exchangers) are used for heat recovery so that the waste heat generated in the production process can be used again in the company. Gaseous or liquid media Waste heat can be in the form of gaseous media (e.g. warm exhaust air, steam, exhaust gases, etc.) or in the form of liquid media (e.g. hot water or other liquids). With the help of heat exchangers, the waste heat can be recovered from both gaseous and liquid media and then made available to the production process at a suitable point as energy in gaseous or liquid media. This process is known as energy recovery or also as heat recovery.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

A flue gas heat exchanger is part of the standard equipment for energy-optimised and environmentally friendly boiler operation. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 15% when using condensing technology — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Every industrial production requires energy in order to make products. Often, electrical or primary energy is induced as heat, used for operation and must then be dissipated, converted or destroyed. Our gwk process engineers analyse and calculate production processes and the overall thermal periphery with the objective of lowering the necessary energy by means of energy recycling, of reducing the energy requirement at the individual stations, of converting energy or using it several times and dissipating it sensibly. The result is considerable energy saving, which results in cost-cutting and contributes to preserving the environment.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

Exhaust air purification and heat recovery systems are generally not standard applications, even if individual assemblies are now modular. We have made it our goal to offer our customers the best solution for their task. To do this, we take a step back with our customers in order to gain an overview of the whole. Together we look at how the exhaust air is generated and try to start our concepts right at the point of origin. Only then can we decide which exhaust air system is the most economical when considering the total cost of ownership and compliance with the limit values. Should an extended consideration be necessary, we can accompany you from basic to authority to detail engineering. In addition, it is not uncommon for pilot tests to be offered, which lead to the later real scale of the systems by means of scaleup. With these consulting and engineering services, we offer you a manufacturerindependent package with which you can make the right decision for your company.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Our heatrecovery systems heat fresh air with the thermal energy of exhaust air and can be placed directly on top of a stenter frame. This system can also be retrofitted for older dryers. The benefits are high energy savings which allow payback periods of less than two years, depending on the layout and process, highly efficient platetype heat exchangers with nonstick coating, optimum ease of maintenance by removable drawersized heat exchanger modules, external cleaning of the heatexchangers in a hot water bath with ultrasonic cleaning equipment, high power density, higher than with usual tubetype heatexchangers.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

With the effective recovery of flue gas heat, you can save up to 14% on fuel and, at the same time, reduce emissions. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 14% when using an additional downstream condensing heat exchanger — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting — Feed water cooling or combustion air preheating as alternatives to the condensing heat exchanger

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Environmentally friendly generation of steam from available waste heat — The perfect addition to energy concepts involving combined heat and power generation — High efficiency through efficient tubular heat exchanger and thermal insulation — Additional efficiency gain thanks to optional integrated economiser — Matched, modular system for easy planning and fast installation

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the recovery of heat from desalinated water/condensate — Increase in system efficiency of up to 2% — Reductions in fuel, cooling water and waste water costs — Fast and easy assembly, requires just a small number of connections before it can be used Highly efficient boiler systems with perfectly matched boiler house components ensure that low levels of energy consumption and emissions are achieved.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the cooling of blow-down water and the recovery of heat from desalinated water/condensate — Increase in system efficiency of up to 2% — Reductions in fuel, cooling water and waste water costs — Rigorous compliance with official requirements thanks to automatic operation — Fast and easy assembly, requires just a small number of connections before it can be used

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

HRUWALLRC is a bidirectional ventilation unit, often described as decentralized or pushpull, with regenerative ceramic heat exchanger. It is intended for single room installation, usually installed in synchronised pairs. The heat exchanger material together with its unique honeycomb structure gives a maximal 82% thermal efficiency ratio (74% acc. to 1254/2014 EU Directive reference measuring point). The operating principle is analogous to HRUWALL unit is working in alternating flow mode, switches the air flow directions every 40120 seconds (pushpull) and it’s equipped with energy efficient EC fan (maximum power consumption is only 6 W for HRUWALLRC15060). The unit casing is made of ABS plastic. A remote controller with LCD display is included in the set. We recommend installing the devices in pairs

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

The heat recovery ventilation unit HRU-PremAIR has an air flow capacity of 350 m3/h at 100 PA. Designed to use aluminum heat exchangers and EPP self-supporting casing. Heat exchangers that are used depend on the model, such as counterflow aluminium heat exchanger (HRV) or counterflow enthalpy exchanger (ERV).

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

Heat recovery ventilation unit HRUPremAIR is a modern device with 350 / 450 or 500 m3/h air flow @ 100 Pa. Unit is made from cutting edge materials aluminim heat exchanger and EPP selfsupporting casing. Depending on the model, following heat exchangers are used counterflow aluminium heat exchanger (HRV) or counterflow enthalpy exchanger (ERV). Enthalpy exchangers in HRUPremAIRE series have a polymer membrane that effectively recovers heat and moisture from the extract air. Such membrane works like a membrane in waterproof trekking clothing i.e. it allows water vapour to pass through, but not liquid water and air. The enthalpy exchanger also blocks the transfer of odours, bacteria and spores. The exchanger material, is needless to say, primarily optimized for maximum heat recovery efficiency. PremAIR air handling units optionally can be equipped with the Constant Flow system, whose task is to maintain a constant air flow in the installation.

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

The HRUSlimAIR heat recovery unit is designed for residential buildings. The HRU has a capacity of 250 m3/h @ 100 Pa, generated by energyefficient EC fans. Thanks to a counterflow heat exchanger made of a plastic (PET), it achieves up to 90% heat recovery An ERV version with an enthalpy exchanger that recovers moisture is also available. Builtin electric preheater protects heat exchanger against freezing, wireless radio communication connects controllers and sensors, and all of it is enclosed inside a selfsupporting, insulating EPP casing. HRUSlimAIR can be installed in up to 3 positions, thanks to a special condensate drain system.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALNOR VENTILATION SYSTEMS LTD

Poland

HRUWALLWI model ductless heat recovery unit comes equipped with a WiFi module. Its basic parameters, including max. heat recovery 82%, airflow rate 60 m3/h, and low sound power level 38 dB (A), are identical to those of the HRUWALL units. Methods for pairing devices and controlling them are different. With the addition of a WiFi module, the device can be connected to a local wireless network and controlled via a mobile app. Moreover, the app allows the pairing of devices by assigning two or more heat recovery units to a group. It is possible to have many groups so that 1 application can serve all HRV units in a building. A temperature sensor and relative humidity sensor are built into the HRUWALLWI, and the app displays their values.

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

HRUWALL is a singleroom decentralized heat recovery unit for concealed installation. The unit comes with a ceramic heat exchanger which boasts a maximum heat recovery ratio of 90% (the nominal heat recovery ratio is η=74.3% as per EN 1314182011). The energyefficient EC fan changes the running direction every 70 seconds to alternate between air supply and air exhaust. Low energy consumption and extremely low operating noise make this heat recovery unit a recommended solution for nonstop operation. The heat recovery unit has three speed levels to choose from, depending on the size of the area and indoor demands. HRUWALL10025 provides a sufficient air change level in areas up to 19m2. HRUWALL15060 provides a sufficient air change level in areas up to 45m2. We recommend installing the devices in pairs.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

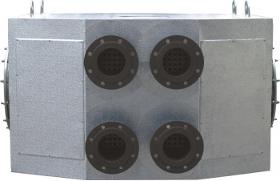

Engines for combined heat and power plants are operated with different fuels, including hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels. In an exhaust gas heat exchanger, the hot exhaust gas from the CHP engines or CHP gas turbines is cooled, in the process heating water, a water-glycol mixture or thermal oil. This thermal energy can be used in a local or district heating system or for other industrial purposes.

Request for a quote

APROVIS

Germany

What you can expect from APROVIS exhaust gas heat exchangers: - Efficient hot water generation in combined heat and power plants - Heating of thermal oil as an energy source - Individual solutions and compact designs - All the main components for the exhaust gas section and gas treatment are combined under one roof: proprietary products developed in-house - Cost-saving and reliable operation of the systems - Maximum functionality, safety and service - Temperature ranges: up to 600°C on the exhaust gas side or up to more than 1,000°C in the high-temperature range - Maximum functionality, safety and service - Temperature ranges: up to 600°C on the exhaust gas side or up to more than 1,000°C in the high-temperature range - Certifications: PED 2014/68/EU, ASME Code, EAC - Can be used in all plants with exhaust gases from hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels - Geared to international standards and directives

Request for a quote

APROVIS

Germany

What you can expect from APROVIS steam generators: - Efficient steam generation in combined heat and power plants - Cost-saving and reliable operation of the systems - Maximum functionality, safety and service - Performance areas: 1 to 25 baro, 100 to 25,000 kg/h - Certifications: PED 2014/68/EU, ASME Code, EAC - Can be used in all plants with exhaust gases from hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels - Geared to international standards and directives - Single, double or triple version for operation with one, two or three engines with completely separate exhaust gas sections - The APROVIS Controlling System (ACS) is individually adapted to each project and is delivered in the required language - Access to the ACS using a modem enables easy fine-tuning of the system or remote maintenance for swift support if and when discrepancies occur during operation

Request for a quote

NOVELTY STEEL

Turkey

A heat exchanger is a device designed for the transfer of internal thermal energy between two or more fluids with different temperatures. Typically, these fluids are separated by a heat transfer surface to prevent mixing. Heat exchangers find applications across various industries, including process, power, petroleum, transportation, air-conditioning, refrigeration, cryogenic, heat recovery, alternate fuels, and more. Examples of heat exchangers encountered in daily life include automobile radiators, condensers, evaporators, air preheaters, and oil coolers. Heat exchangers can be classified in numerous ways based on their design and applications.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electric duct heater Electrical duct heater type “LEH-R” are intended for the heating of gaseous media. The main applications are the heating of air in ventilation - / air conditioning or heat-recovery installations. Wide use areas are applications of the process - / environment-technology i.e. at the catalytic afterburning of exhaust fumes or drying ovens or in the plastic - / textile or paper industry. Through a variable construction concept, diverse use possibilities emerge. The application of highly compacted electrical heating elements with high purity compacted magnesium oxide powder sheathed metal tube and the direct heat transfer at the medium to be heated leads to an efficient realization of the electric energy to thermal energy. Special materials of acid constant rustproof steel stand for the heating of aggressive media by disposal. Alternatively, the heaters can be delivered also in the materials INCOLOY, INCONEL, HASTELLOY and MONEL. The duct heaters essentially consist of the following main-components: Duct with adapters to flanges DIN EN 1092 Rod heating elements Temperature Sensors (Thermostat / Thermocouple / RTD) Electrical terminal box

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electric duct heater Electrical duct heater type “LEH-K” are intended for the heating of gaseous media. The main applications are the heating of air in ventilation - / air conditioning or heat-recovery installations. Wide use areas are applications of the process - / environment-technology i.e. at the catalytic afterburning of exhaust fumes or drying ovens or in the plastic - / textile or paper industry. Through a variable construction concept, diverse use possibilities emerge. The application of highly compacted electrical heating elements with high purity compacted magnesium oxide powder sheathed metal tube and the direct heat transfer at the medium to be heated leads to an efficient realization of the electric energy to thermal energy. Special materials of acid constant rustproof steel stand for the heating of aggressive media by disposal. Alternatively, the heaters can be delivered also in the materials INCOLOY, INCONEL, HASTELLOY and MONEL. The duct heaters essentially consist of the following main-components: Duct with flat flanges Rod heating elements Temperature Sensors (Thermostat / Thermocouple / RTD) Electrical terminal box

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electric Air heater Electrical air heater type “LEH-A” are intended for the heating of gaseous media. The main applications are the heating of air in ventilation - / air conditioning or heat-recovery installations. Wide use areas are applications of the process - / environment-technology i.e. at the catalytic afterburning of exhaust fumes or drying ovens or in the plastic - / textile or paper industry. Through a variable construction concept, diverse use possibilities emerge. The application of highly compacted electrical heating elements with high purity compacted magnesium oxide powder sheathed metal tube and the direct heat transfer at the medium to be heated leads to an efficient realization of the electric energy to thermal energy. Special materials of acid constant rustproof steel stand for the heating of aggressive media by disposal. Alternatively, the heaters can be delivered also in the materials INCOLOY, INCONEL, HASTELLOY and MONEL. The air heater essentially consist of the following main-components: Process flange Rod heating elements Temperature Sensors (Thermostat / Thermocouple / RTD) Electrical terminal box

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Items that have initially been bagged using a machine from Hugo Beck often need to be shrunk so as to ensure a tight-fitting film and the perfect packaging finish to meet the highest standards. Adapted for each packaging system, we supply the appropriate shrink tunnel in all sizes and performance ranges for the production of high-quality shrink packaging. As such, we manufacture shrink tunnels in a number of versions, with a variety of rods and chains that operate like a link mesh belt. Textile mesh belts are also possible for very light products. In each case, the length of the shrink tunnel depends on the speed of packaging and on the film material selected. State-of-the-art air ducting and heat recovery ensure efficient energy use, helping us to contribute to both protection of the environment and reducing energy costs. The decision on whether to use a shrink tunnel with circulating air or convection principle is defined depending on the individual product application of the customer.

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

• operating temperatures up to 600°C (standard) • completely made of stainless steel • heat recovery factor up to 85% • pressure-resistant up to 150 mbar • completely welded • high degree of efficiency • without seelings • up to 100% gas-tight • low maintenance • small construction volume • flexible coordination due to single-item or small-lot production • distance between plates from 3.5 mm to 7 mm • available in the structural shapes K, L, U and LU • complete seperation of the two gas flows • different current lines possible • different volume flows for exhaust and feed air, applicable for the temperature control of useful heat Structural shape In principle, the shape is arbitrary. The choice takes place after consulting with the customer and with similar power are no costs involved. It depends on the technical demands of the application. The structural shape X (crossflow) isn't possible with the ´ THERMO GAS System. Shape LU This structural s

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

• operating temperatures up to 600°C (standard) • completely made of stainless steel • heat recovery factor up to 85% • pressure-resistant up to 150 mbar • completely welded • high degree of efficiency • without seelings • up to 100% gas-tight • low maintenance • small construction volume • flexible coordination due to single-item or small-lot production • distance between plates from 3.5 mm to 7 mm • available in the structural shapes K, L, U and LU • complete seperation of the two gas flows • different current lines possible • different volume flows for exhaust and feed air, applicable for the temperature control of useful heat no costs involved Shape U This structural shape is especially qualified for small plate heat exchangers. This structural shape is although qualified for plate heat exchangers which should streamed vertically.

Request for a quoteResults for

Heat recovery - Import exportNumber of results

89 ProductsCountries

Company type

Category

- Heat recovery systems (27)

- Boilers, industrial (12)

- Heat exchangers (12)

- Components and parts for small household appliances (11)

- Air purification - equipment and systems (3)

- Refrigeration plants and equipment, commercial and industrial (3)

- Air conditioning, aeration and ventilation equipment (2)

- Energy - production plants and equipment (2)

- Plastics - machines and material for industry (2)

- Ventilators and fans - industrial (2)

- Boilermaking, heavy (1)

- De-humidifying equipment (1)

- Dry-cleaning machines (1)

- Filters, liquid (1)

- Fittings, pipe, tube and hose - plastic (1)

- Gas and oil - exploitation (1)

- Gas filters (1)

- Heating, domestic - installations and equipment (1)

- Industrial furnaces (1)

- Laboratory equipment and instruments (1)