- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- turnkey lines

Results for

Turnkey lines - Import export

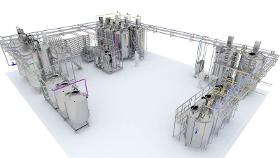

SAMAG MACHINE TOOLS GMBH

Germany

KNOW-HOW & EXPERIENCE, COMMITMENT & IDEAS, RELIABILITY & FLEXIBILITY – SAMAG, MACHINE TOOLS FROM THURINGIA SINCE 1873! WE SEE OURSELVES AS DEVELOPERS AND MANUFACTURERS OF MACHINE CONCEPTS, FROM INDIVIDUAL MACHINES TO TURNKEY LINES. THE FOCUS OF OUR PRODUCTS IS ON MILLING AND DEEP DRILLING TECHNOLOGIES. Separated from the SAMAG Group, we have been independently continuing the tradition of mechanical engineering in Saalfeld / Thuringia as SAMAG Machine Tools GmbH since January 2020. With 140 employees, we draw on the experience of more than 145 years of machine tools for metal cutting. One of our strengths is the high level of technological solution expertise with which we help our customers worldwide achieve sustainable success. As an international machine tool manufacturer, our most important sales markets are the automotive industry, tool and mold making and mechanical engineering.

Request for a quote

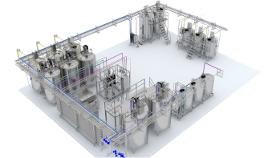

WHITE STEEL GMBH

Germany

SPECIFICATION Turnkey feature Milk Double jackets cooling collecting tanks Storage feeding tank Processing section Rotary bottles washing system Pasteurizer machines Homogenizer machine Rotary Milk, yogurt and cream cheese filling, sealing and capping machines Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION: High stability on high capacity. Can handle multiple product viscosity and types Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: Turnkey feature Milk Double jackets cooling collecting tanks Storage feeding tank Processing section Rotary bottles washing system Pasteurizer machines Homogenizer machine Rotary Milk, yogurt and cream cheese filling, sealing and capping machines Compact design Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

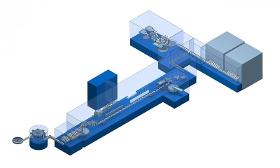

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Since 1994, the 100% Venjakob affiliated company Nutro, USA has designed and installed turnkey robotic paint lines with robots from the most well- recognized and trusted robot suppliers such as ABB, Fanuc, Kuka, Motoman, and Staubli. Robotic paint lines provide the ultimate in precision and repeatability in painting performance. Due to the reduction in downtimes, training and personnel costs, a robotic paint system is ideally suited for paint application lines where uniform coating of complex 3-dimensional parts is needed. In addition to the solid construction, these robotic paint lines offer the safety needed for robots with the latest PLC and PC interfaces. This makes programming and operating simple and error-free for paint line personnel. Robot painters by Nutro are used for the following parts: Venjakob can provide your company with a complete new line or integrate a robot painter into an existing finishing line.

Request for a quote

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

Do you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA PHARMA GMBH

Germany

Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

Results for

Turnkey lines - Import exportNumber of results

7 ProductsCountries

Company type