- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tool%20manufacturing

Results for

Tool%20manufacturing - Import export

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

Due to our 25 years of experience we are able to produce high-class qualities on favourable terms in the field of tool manufacturing as well. You are looking for the optimal tool, that matches your needs and that keeps your costs low even in the long term? No matter whether we are assigned by automotive, electric or any other sector of industry: we are your tool partners! Let us counsel you individually and you will profit with our nice price-performance ratio soon. Besides multi-part press tools and by using modern CAD-techniques cutting tools we produce deep drawn tools, bending tools and fixture constructions for stamping, bending and drawing parts with a press capacity up to 2800 kN and a sheet thickness of 4.0 mm. Screw threads can be formed non-cuttingly up to M12 during the stamping process. Our tool maker craft tools routinely and professionally that bare a high complexity. Because we can use our experience of long duration in manufacturing precise tools, ...

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Nitriding treatment is a chemical heat treatment process in which nitrogen atoms penetrate the surface of the workpiece at a certain temperature and in a certain medium. The products treated with nitriding have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance. The general process of nitriding process :1. Pretreatment: clean, remove oil and dry the metal surface to ensure that the surface is clean and free of impurities. 2. Nitriding treatment: The metal is placed in an atmosphere containing nitrogen and treated at high temperatures to form a nitriding layer on the surface of the metal. 3. Post-treatment: Clean and cool the metal surface after nitriding to remove the residual nitride layer and prevent its oxidation. The nitriding process is of great importance for many industrial fields, such as tool manufacturing and automotive parts manufacturing.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Static tools form one of the EWS core areas. There is no other manufacturer in the world offering such a variety of products: More than 20,000 different tool holders are available for machine operators. Our portfolio includes VDI tool holders with shaft diameters of 16-80 as well as block tool holders of BMT55-BMT85 to machine-specific holders for MAZAK, Okuma or Mori Seiki, to name just a few. We also offer prism holders according to DIN 69881 (VDI3425 Bl.3) in all nominal sizes. Our standard portfolio includes Capto, HSK, KM and ABS adaptations in addition to the standard holders. Moreover, our scope of supply includes special holding fixtures made according to customer drawings or innovative solutions of the EWS engineers designed to master production engineering challenges. The tool holders are manufactured at our factory in Uhingen and rightly carry the label: Made in Germany! Boring bar holder BMT Capto C4 Double boring bar holder Capto Bar Gripper Infee

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Gear hobbing on CNC lathes without B-axis Years ago, EWS was the first tool manufacturer to offer gear hobbing heads in its standard range, and has continued to develop the holders for gearing technology ever since then. With this technology, it became possible for the first time to produce external gearing on machines without a Y/B-axis. In contrast to a standard milling wheel holder, the tool head of the EWS modular cutter can be swivelled about the axis of the shank. This offers users the advantage of substituting a B-axis with a comparatively small investment. In the meantime, module 3 has become commonplace on VDI40/BMT65/BMT75 machines. The tool heads have become more stable at the same time as being more user-friendly. The alignment system using a sinusoidal profile has come into widespread use and saves considerable alignment and setup times. Operating instructions, flyers and press reports can be found in our download portal Video: Gear hobbing on the

Request for a quote

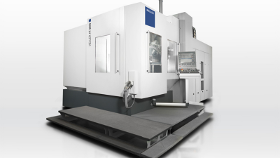

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for powerful complete machining Setting standards in 5-axis: 5-sided and 5-axis simultaneous machining in HELLER quality Highlights Maximum output at optimum quality due to HELLER's extensive process experience Higher availability thanks to adequate speeds and proven HELLER components Innovative spindle technology in three variants providing optimum process stability (swivel head with PCU 63 or SCU 63, fork head with PCT 63) Two control options: Heidenhain iTNC 530 or Siemens Sinumerik 840D sl Advantages Reduced costs thanks to flexible complete machining Optimised life-cycle costs due to innovative manufacturing concept Two machine variants for maximum manufacturing flexibility: workshop machine FT (table loading) for machining of individual parts in tool and die manufacturing and production machine FP (pallet changer) for series production

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

We manufacture individual parts and assemblies according to drawings, data or samples. We have a wide range of profiles in different steel grades and aluminum in stock. Our machinery enables us high flexibility.

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

For punching problems that cannot be solved with punching units in series and special designs, we manufacture tools and devices for every purpose.

Request for a quote

BVS ELECTRONICS GMBH

Germany

HELLER uniPro 90 Machine tools manufactured by HELLER are used around the world in the machining sector. Many of the older processing centres are using the "uniPro 90" controller for which we offer completely reconditioning repairs across the entire product range. In addition we are selling new, replacement and exchange parts. We are also able to test these HELLER controllers on our internally developed test stand and guarantee full functionality following repair. By using original components for every repair, we can also offer you an 24month warranty* on the complete assembly. The product portfolio for the HELLER uniPro 90 product range currently consists of inputs and outputs, plugin cards from the ACPU90 range, control panels, system cards and power modules.

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydropneumatic intensifier Foot valve operated Max. power at 10 bar = 50 KN Stroke = 37 mm Max. daylight = 200 mm Working range: ram to back wall = 110 mm Swiveling table to use tools to manufacture holes for sash bars

Request for a quote

INFICON GMBH

Germany

The INFICON SKY CDG025D Capacitance Diaphragm Gauge line of highly accurate temperature compensated manometers is designed for stable performance in harsh manufacturing tool environments. Advanced digital electronics improve gauge performance and offer easy handling features such as one pushbutton zero function. New Version with 2wire current Loop is now available. The corrosion resistant ultra pure ceramic sensor provides excellent zero stability with a long life expectancy of several million pressure cycles, including atmospheric bursts. A unique sensor shielding (patent pending) protects the gauge from process contamination. A robust mechanical design and digital electronics improve EMC compatibility, long term stability and temperature compensation. The CDG025D sets new standards for fast stability after power on and fast recovery from atmospheric pressure exposure. (1) Non-linearity, hysteresis, repeatability at 25°C ambient operating temperature without temperature effects...

Request for a quote

INFICON GMBH

Germany

The INFICON SKY CDG025D Capacitance Diaphragm Gauge line of highly accurate temperature compensated manometers is designed for stable performance in harsh manufacturing tool environments. Advanced digital electronics improve gauge performance and offer easy handling features such as one pushbutton zero function and setpoint adjustment. The corrosion resistant ultra pure ceramic sensor provides excellent zero stability with a long life expectancy of several million pressure cycles, including atmospheric bursts. A unique sensor shielding (patent pending) protects the gauge from process contamination. A robust mechanical design and digital electronics improve EMC compatibility, long term stability and temperature compensation. The CDG025D sets new standards for fast stability after power on and fast recovery from atmospheric pressure exposure. (1) Non-linearity, hysteresis, repeatability at 25°C ambient operating temperature without temperature effects after 2 hours operation. (2)...

Request for a quote

INFICON GMBH

Germany

The INFICON SKY CDG025D Capacitance Diaphragm Gauge line of highly accurate temperature compensated manometers is designed for stable performance in harsh manufacturing tool environments. Advanced digital electronics improve gauge performance and offer easy handling features such as one pushbutton zero function and setpoint adjustment. The corrosion resistant ceramic sensor provides excellent zero stability with a long life expectancy of several million pressure cycles, including atmospheric bursts. A unique sensor shielding (patent pending) protects the gauge from process contamination. A robust mechanical design and digital electronics improve EMC compatibility, long term stability and temperature compensation. The CDG025D sets new standards for fast stability after power on and fast recovery from atmospheric pressure exposure. (1) Non-linearity, hysteresis, repeatability at 25 °C ambient operating temperature without temperature effects after 2 hours operation. (2) Increase 10...

Request for a quote

SAMSYS GMBH

Germany

Do you want to use the OnRobot grippers as double grippers? The Dual Quick Changer double gripper system allows the use of different OnRobot gripping tools in one pass. With this innovative solution, you can use two RG2 grippers or one RG6 gripper with a VG10 – it’s up to you. Switch quickly and seamlessly between our tools with the Dual Quick Changer to maximize the utilization of your robots. With the Dual Quick Changer, throughput times can be accelerated and thus the productivity of your plant increased. Not only suitable for OnRobot products. The DUAL Quick Changer can also be combined with tools from other manufacturers. It can also be used for own constructions. Another example are existing tools, which can also be equipped with the OnRobot quick-change system. The Dual Quick Changer is the alternative to the Quick Changer. This makes it easy to install two tools on one robot arm.

Request for a quote

SAMSYS GMBH

Germany

The Quick Changer system enables quick and easy tool change. It has a low weight, a low installation height and is designed for a payload of up to 20 kg. It is patented, reliable and equipped with a user-friendly connection mechanism. Particularly secure locking structure and locking springs. The Quick Changer system is a unique product and ideal for all collaborative robotic applications. The Quick Changer is the easiest and fastest tool changer. Simply everything you need in one package. Not only suitable for OnRobot products. It can also be combined with tools from other manufacturers. It can also be used for own constructions. Another example is the use of existing tools. These can also be equipped with OnRobot’s quick change system. The Quick Changer is alternatively also available as Dual Quick Changer. This makes it easy to install two tools on one robot arm.

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Round belts are used for conveying in the textile, wood-working, ceramic, packaging and chemical industries.Siegling Transilon round belts serve as efficient drive elements in both precision tool and machinery manufacturing. Siegling Round belts have also proven their reliability as drive elements for live roller conveyor repeatedly. Their great flexibility and elasticity make any turn possible.

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

State-of-the-art crane systems move the heaviest construction and production components on construction sites and in production halls. MACK solutions are available to help you make the most of your potential! Cranes and hoists are mostly used in demanding situations, where space is limited and conditions are very hot or cold, very damp or very dry. This means: Even under the toughest indoor or outdoor conditions, extension arms and grippers have to be reliably supplied with energy and data in order to carry our their lifting operations without any disturbances. With our carbon brush components we support you as system suppliers, finding ‘your’ solution, no matter where you are in the development process. Design, manufacturing, tool making and assembly – all from a single provider. And done in-house. Applications in crane technology Our solutions Our services

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Profiline – This EZM brand name stands for cold-drawn standard sec-tions and special sections to customer drawings in virtually all steel materials. Optimum heat-treatment, pickling and coating facilities are available for every material group. As a result of the continuous improvement of our in-house tool production operations, EZM can manufacture sections whose geometry and shape are as near as possible to the net shape, maintaining the tightest tolerances and producing flawless surfaces. Our cold-drawn sections are successfully used when metal cutting is uneconomical due to the great effort and material losses involved, or when the section is to be given specific properties that can only be achieved by targeted cold-forming. In our plant EZM Profil Bearbeitung, based in Rohr/Thüringen, sections are manufactured by machining up to 6,200 mm length and a maximum crossing-section of 125 mm, which are needed for for example for linear guides in the machine and plant...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Profiline – This EZM brand name stands for cold-drawn standard sec-tions and special sections to customer drawings in virtually all steel materials. Optimum heat-treatment, pickling and coating facilities are available for every material group. As a result of the continuous improvement of our in-house tool production operations, EZM can manufacture sections whose geometry and shape are as near as possible to the net shape, maintaining the tightest tolerances and producing flawless surfaces. Our cold-drawn sections are successfully used when metal cutting is uneconomical due to the great effort and material losses involved, or when the section is to be given specific properties that can only be achieved by targeted cold-forming. In our plant EZM Profil Bearbeitung, based in Rohr/Thüringen, sections are manufactured by machining up to 6,200 mm length and a maximum crossing-section of 125 mm, which are needed for for example for linear guides in the machine and plant...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Profiline – This EZM brand name stands for cold-drawn standard sec-tions and special sections to customer drawings in virtually all steel materials. Optimum heat-treatment, pickling and coating facilities are available for every material group. As a result of the continuous improvement of our in-house tool production operations, EZM can manufacture sections whose geometry and shape are as near as possible to the net shape, maintaining the tightest tolerances and producing flawless surfaces. Our cold-drawn sections are successfully used when metal cutting is uneconomical due to the great effort and material losses involved, or when the section is to be given specific properties that can only be achieved by targeted cold-forming. In our plant EZM Profil Bearbeitung, based in Rohr/Thüringen, sections are manufactured by machining up to 6,200 mm length and a maximum crossing-section of 125 mm, which are needed for for example for linear guides in the machine and plant...

Request for a quote

SPIROL

Germany

SPIROL offers Spacers specifically designed for use in conveyor systems and garage door hinge assemblies. Both SPIROL's Conveyor Spacers and Garage Door Spacers are manufactured from galvanised steel to provide the necessary strength and corrosion protection at a fraction of the cost of plated cutoff tubing and machined bushings. SPIROL stocks the raw material and tooling required to manufacture the standard sizes of Conveyor Spacers and Garage Door Spacers. Intermediate lengths can be produced without additional tooling.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

KNOW-HOW & EXPERIENCE, COMMITMENT & IDEAS, RELIABILITY & FLEXIBILITY – SAMAG, MACHINE TOOLS FROM THURINGIA SINCE 1873! WE SEE OURSELVES AS DEVELOPERS AND MANUFACTURERS OF MACHINE CONCEPTS, FROM INDIVIDUAL MACHINES TO TURNKEY LINES. THE FOCUS OF OUR PRODUCTS IS ON MILLING AND DEEP DRILLING TECHNOLOGIES. Separated from the SAMAG Group, we have been independently continuing the tradition of mechanical engineering in Saalfeld / Thuringia as SAMAG Machine Tools GmbH since January 2020. With 140 employees, we draw on the experience of more than 145 years of machine tools for metal cutting. One of our strengths is the high level of technological solution expertise with which we help our customers worldwide achieve sustainable success. As an international machine tool manufacturer, our most important sales markets are the automotive industry, tool and mold making and mechanical engineering.

Request for a quote

RONIX GMBH

Germany

Every project starts with measurements! Simple precise measurements make a complex project possible and that is not going to happen if you don’t use an accurate measuring tool. Ronix has manufactured various high-quality measuring tools to meet various needs. Ronix RH-9502 laser level is a premium tool from this high-tech line-up. Ronix RH-9502 is a Laser Level with the accuracy of ±2mm in 5 meters which can be used in almost all kinds of leveling tasks. The horizontal 360˚ plane and vertical 180˚ line makes different type of indoor and outdoor measurements possible. The IP54 protection rating of the RH-9502 ensures its resistance against water and dust.

Request for a quote

EWOQE GMBH & CO. KG

Germany

EWOQE is your expert in Rapid Tooling, especially for prototype initial samples. Our comprehensive range of 3D printing processes, including FDM, SLS, MJF, and SLA, offers fast, cost-efficient, and high-quality solutions for your Rapid Tooling needs. Our experienced team is here to support you in the design and manufacturing of Rapid Tooling components, regardless of their size or quantity. We understand the urgency and requirements of the industry for high-quality prototypes and provide you with precisely manufactured components that meet your specifications. Thanks to our additive manufacturing technologies, we can reproduce complex geometries and fine details, helping you quickly obtain high-quality prototype initial samples. Our express service ensures rapid turnaround times to optimize your time-to-market and efficiently advance your projects.

Request for a quote

SUPER-FILAMENT EINE MARKE DER ADDITIVE MATERIALS GMBH

Germany

Our extensive expertise spans various applications, including model construction, prototyping, and the production of tools for manufacturing technology. Consistent High Quality and Color Accuracy Across Batches: Our unwavering commitment to consistently high quality and color accuracy across batches allows you, as a customer, to fully focus on the production of your product. Wide Standard Product Portfolio: With a broad standard product portfolio, we offer an impressive selection of materials and colors for various 3D printing applications. From classic materials like PLA, PET-G, ASA, ABS to High-Performance Biopolymers and wood filaments, we meet your most demanding requirements. Custom Manufacturing: Our flexibility is evident in the option for custom manufacturing. Decide not only on material and color but also on spool type and packaging size, whether it's a standard plastic spool, recycled plastic spool, or environmentally friendly cardboard spool.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK GMBH

Germany

As a competent partner in the field of tool making, we perform repair, maintenance and modification work on our customers' tools. We also carry out development work on the tools according to the customer's requirements and drawings. These extremely high-quality tools are used in a variety of production processes and serve as quality assurance for our industrial customers during the manufacture of their products. The expertise and knowledge we bring to bear when carrying out customisation, repair and maintenance work on special-purpose and custom-made tools assists our customers in finding the optimal solution. Our tools are purchased by manufacturing operations and end users in various branches of industry. SCHMIDT Zerspanungstechnik boasts state-of-the-art CNC manufacturing technology, a high degree of vertical integration and produces everything under one roof with its team of highly trained employees.

Request for a quote

RONIX GMBH

Germany

How many times have you had problem fastening hart-to-reach bolts and nuts? No need to worry about them anymore. Ronix Ronix Extension Bar 25cm is in the market to help you fasten all sizes of bolts and nuts in any position. Ronix Extension Bar 25cm is just what you need to carry along with your socket set in order to be able to deal with all kinds of bolts and nuts. Ronix uses the best and highest-quality raw material in manufacturing hand tools. these extension bars are made of superior chrome-vanadium material to increase torque and unique hardness. This high-strength chrome vanadium steel extensions provide high torque for greater turning power. This extension bars are equipped with 3-layer chrome coating which protect the tool from corrosion and rusting. these extension bars are designed remain locked onto the drive until you push the quick-release disengage button.

Request for a quote

RONIX GMBH

Germany

Ronix uses the best and highest-quality raw material in manufacturing hand tools. these extension bars are made of superior chrome-vanadium material to increase torque and unique hardness. This high-strength chrome vanadium steel extensions provide high torque for greater turning power. This extension bars are equipped with 3-layer chrome coating which protect the tool from corrosion and rusting. these extension bars are designed remain locked onto the drive until you push the quick-release disengage button.

Request for a quote

RONIX GMBH

Germany

Ronix uses the best and highest-quality raw material in manufacturing hand tools. these extension bars are made of superior chrome-vanadium material to increase torque and unique hardness. This high-strength chrome vanadium steel extensions provide high torque for greater turning power. This extension bars are equipped with 3-layer chrome coating which protect the tool from corrosion and rusting. these extension bars are designed remain locked onto the drive until you push the quick-release disengage button.

Request for a quote

RONIX GMBH

Germany

Ronix uses the best and highest-quality raw material in manufacturing hand tools. these extension bars are made of superior chrome-vanadium material to increase torque and unique hardness. This high-strength chrome vanadium steel extensions provide high torque for greater turning power. This extension bars are equipped with 3-layer chrome coating which protect the tool from corrosion and rusting. these extension bars are designed remain locked onto the drive until you push the quick-release disengage button.

Request for a quoteResults for

Tool%20manufacturing - Import exportNumber of results

52 ProductsCountries

- Germany (52)

- Bonn, Düsseldorf and North Rhine and Westphalia (13)

- Frankfurt am Main and Hesse (8)

- Hannover and Lower Saxony (3)

- Kiel and Schleswig-Holstein (3)

- Leipzig and Saxony (1)

- Mainz and Rheinland-Pfalz (5)

- Munich, Nuremberg and Bavaria (6)

- Saarbrücken and Saarland (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (9)

- Weimar and Thuringia (3)

Company type

Category

- Tools, pneumatic (5)

- Adjustment - machine tools (2)

- Laser - cutting and welding machines (2)

- Milling - machine tools (2)

- Moulds and patterns (2)

- Robotics (2)

- Tools & Hardware (2)

- Prototypes, industrial (1)

- Automation - systems and equipment (1)

- Construction - Machines & Equipment (1)

- Dynamos (1)

- Forming - steels and metals (1)

- Hydraulic tools (1)

- Industrial cutting machine tools (1)

- Industrial tools (1)

- Injection moulding of rubber and plastic (1)

- Machine tools, metal machining - parts and accessories (1)

- Mechanical engineering - custom work (1)

- Metalworking hand tools, non-power (1)

- Milling - steels and metals (1)