- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tool%20manufacturing

Results for

Tool%20manufacturing - Import export

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

Due to our 25 years of experience we are able to produce high-class qualities on favourable terms in the field of tool manufacturing as well. You are looking for the optimal tool, that matches your needs and that keeps your costs low even in the long term? No matter whether we are assigned by automotive, electric or any other sector of industry: we are your tool partners! Let us counsel you individually and you will profit with our nice price-performance ratio soon. Besides multi-part press tools and by using modern CAD-techniques cutting tools we produce deep drawn tools, bending tools and fixture constructions for stamping, bending and drawing parts with a press capacity up to 2800 kN and a sheet thickness of 4.0 mm. Screw threads can be formed non-cuttingly up to M12 during the stamping process. Our tool maker craft tools routinely and professionally that bare a high complexity. Because we can use our experience of long duration in manufacturing precise tools, ...

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Nitriding treatment is a chemical heat treatment process in which nitrogen atoms penetrate the surface of the workpiece at a certain temperature and in a certain medium. The products treated with nitriding have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance. The general process of nitriding process :1. Pretreatment: clean, remove oil and dry the metal surface to ensure that the surface is clean and free of impurities. 2. Nitriding treatment: The metal is placed in an atmosphere containing nitrogen and treated at high temperatures to form a nitriding layer on the surface of the metal. 3. Post-treatment: Clean and cool the metal surface after nitriding to remove the residual nitride layer and prevent its oxidation. The nitriding process is of great importance for many industrial fields, such as tool manufacturing and automotive parts manufacturing.

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

For punching problems that cannot be solved with punching units in series and special designs, we manufacture tools and devices for every purpose.

Request for a quote

INFICON GMBH

Germany

The INFICON SKY CDG025D Capacitance Diaphragm Gauge line of highly accurate temperature compensated manometers is designed for stable performance in harsh manufacturing tool environments. Advanced digital electronics improve gauge performance and offer easy handling features such as one pushbutton zero function. New Version with 2wire current Loop is now available. The corrosion resistant ultra pure ceramic sensor provides excellent zero stability with a long life expectancy of several million pressure cycles, including atmospheric bursts. A unique sensor shielding (patent pending) protects the gauge from process contamination. A robust mechanical design and digital electronics improve EMC compatibility, long term stability and temperature compensation. The CDG025D sets new standards for fast stability after power on and fast recovery from atmospheric pressure exposure. (1) Non-linearity, hysteresis, repeatability at 25°C ambient operating temperature without temperature effects...

Request for a quote

INFICON GMBH

Germany

The INFICON SKY CDG025D Capacitance Diaphragm Gauge line of highly accurate temperature compensated manometers is designed for stable performance in harsh manufacturing tool environments. Advanced digital electronics improve gauge performance and offer easy handling features such as one pushbutton zero function and setpoint adjustment. The corrosion resistant ultra pure ceramic sensor provides excellent zero stability with a long life expectancy of several million pressure cycles, including atmospheric bursts. A unique sensor shielding (patent pending) protects the gauge from process contamination. A robust mechanical design and digital electronics improve EMC compatibility, long term stability and temperature compensation. The CDG025D sets new standards for fast stability after power on and fast recovery from atmospheric pressure exposure. (1) Non-linearity, hysteresis, repeatability at 25°C ambient operating temperature without temperature effects after 2 hours operation. (2)...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Profiline – This EZM brand name stands for cold-drawn standard sec-tions and special sections to customer drawings in virtually all steel materials. Optimum heat-treatment, pickling and coating facilities are available for every material group. As a result of the continuous improvement of our in-house tool production operations, EZM can manufacture sections whose geometry and shape are as near as possible to the net shape, maintaining the tightest tolerances and producing flawless surfaces. Our cold-drawn sections are successfully used when metal cutting is uneconomical due to the great effort and material losses involved, or when the section is to be given specific properties that can only be achieved by targeted cold-forming. In our plant EZM Profil Bearbeitung, based in Rohr/Thüringen, sections are manufactured by machining up to 6,200 mm length and a maximum crossing-section of 125 mm, which are needed for for example for linear guides in the machine and plant...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Profiline – This EZM brand name stands for cold-drawn standard sec-tions and special sections to customer drawings in virtually all steel materials. Optimum heat-treatment, pickling and coating facilities are available for every material group. As a result of the continuous improvement of our in-house tool production operations, EZM can manufacture sections whose geometry and shape are as near as possible to the net shape, maintaining the tightest tolerances and producing flawless surfaces. Our cold-drawn sections are successfully used when metal cutting is uneconomical due to the great effort and material losses involved, or when the section is to be given specific properties that can only be achieved by targeted cold-forming. In our plant EZM Profil Bearbeitung, based in Rohr/Thüringen, sections are manufactured by machining up to 6,200 mm length and a maximum crossing-section of 125 mm, which are needed for for example for linear guides in the machine and plant...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Profiline – This EZM brand name stands for cold-drawn standard sec-tions and special sections to customer drawings in virtually all steel materials. Optimum heat-treatment, pickling and coating facilities are available for every material group. As a result of the continuous improvement of our in-house tool production operations, EZM can manufacture sections whose geometry and shape are as near as possible to the net shape, maintaining the tightest tolerances and producing flawless surfaces. Our cold-drawn sections are successfully used when metal cutting is uneconomical due to the great effort and material losses involved, or when the section is to be given specific properties that can only be achieved by targeted cold-forming. In our plant EZM Profil Bearbeitung, based in Rohr/Thüringen, sections are manufactured by machining up to 6,200 mm length and a maximum crossing-section of 125 mm, which are needed for for example for linear guides in the machine and plant...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Profiline – This EZM brand name stands for cold-drawn standard sec-tions and special sections to customer drawings in virtually all steel materials. Optimum heat-treatment, pickling and coating facilities are available for every material group. As a result of the continuous improvement of our in-house tool production operations, EZM can manufacture sections whose geometry and shape are as near as possible to the net shape, maintaining the tightest tolerances and producing flawless surfaces. Our cold-drawn sections are successfully used when metal cutting is uneconomical due to the great effort and material losses involved, or when the section is to be given specific properties that can only be achieved by targeted cold-forming. In our plant EZM Profil Bearbeitung, based in Rohr/Thüringen, sections are manufactured by machining up to 6,200 mm length and a maximum crossing-section of 125 mm, which are needed for for example for linear guides in the machine and plant...

Request for a quote

FRIMO GROUP GMBH

Germany

Composites are engineered materials made from two or more materials with significantly different physical or chemical properties. Their mechanical and physical properties depend on the type and proportion of the base materials and the parameters of the manufacturing process. Due to composites, very light and durable plastic parts can be produced. Composites may be prepared as layers , fibers, particles or penetrating composites , but the actual composite material usually only arises during the shaping process in the tool . FRIMO has extensive technical expertise and many years of experience in developing and manufacturing plants and tools to process composite materials such as CFK, GFK, NFPP, HFPP, LFT, GMT and BMC and supplies for the production processes such as RRIM, SRIM / GMPU, Long Fiber Technologies, NFI, or RTM tailor-made manufacturing equipment.

Request for a quote

FRIMO GROUP GMBH

Germany

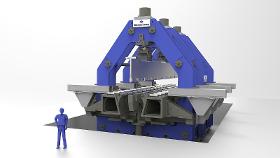

Successful for decades and constantly evolving Regardless of the desired kinematics, clamping force or clamping area, FRIMO customized tool/mold carriers can be integrated into single-station or multi-station units, rotary table systems or PURe Track overhead conveyors. FRIMO's more than 1,000 manufactured and delivered tool/mold carriers serve as proof of superior quality and reliability. Special Types: FRIMO is your specialist when it comes to optimal tooling concepts based on customer demands. Our product portfolio covers a broad spectrum of possible special designs, such as window frames, damping units, cast skins, skis, acoustic components, boilers, glass roofs, steering wheels, seat cushions and head rests.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp is number one in tailor-made plants for the leading manufacturers of pipeline pipes. These large-diameter pipes with longitudinal weld seams are manufactured using crimping, U-forming, and O-forming presses. Compared to other processes on the market, these three presses achieve high production outputs of up to 30 pipes per minute regardless of the pipe diameter. For these large presses featuring our proven metal frame construction, the heavy component parts and tools are manufactured in our in-house foundry. The three hydraulic presses present the essential forming units of a modern production line for longitudinally welded pipes with lengths of up to 18 m in three forming steps. For each of the three forming steps, Siempelkamp oers the optimal press and the associated equipment for the forming line (e.g., pipe transport, lubrication, measuring).

Request for a quoteResults for

Tool%20manufacturing - Import exportNumber of results

13 ProductsCompany type