- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- titanium alloys

Results for

Titanium alloys - Import export

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Edelstahlzieherei Mark is traditionally a manufacturer of speciality products, whose uses also include medical equipment. To do justice to the high, specific demands on this product segment and this market, we have given these products a special status within the company. EZM offers EZM Chirusteel and EZM Chirutan products under the brand family name EZM Chiruline. In addition to placing special orders, customers can also fall back on medical grades and versions kept in stock. EZM Edelstahlzieherei Mark offers its customers in the medical equipment sector an extensive range of materials and versions – from stainless materials to titanium, and from ground round bars to sections. Drill wires Implants/Bone plates Implants/Screws Titanium implants >> Current alloy surcharges >> Current scrap surcharges VERSIONS AND FORMS SUPPLIED Drawing From 2.0 mm to 28.0 mm round, tolerance zone IT 9 Min. bar length 2,000 mm Max. bar length 5,000 mm (2.0 mm to 6.0 mm round Max. bar...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Edelstahlzieherei Mark is traditionally a manufacturer of speciality products, whose uses also include medical equipment. To do justice to the high, specific demands on this product segment and this market, we have given these products a special status within the company. EZM offers EZM Chirusteel and EZM Chirutan products under the brand family name EZM Chiruline. In addition to placing special orders, customers can also fall back on medical grades and versions kept in stock. EZM Edelstahlzieherei Mark offers its customers in the medical equipment sector an extensive range of materials and versions – from stainless materials to titanium, and from ground round bars to sections. Drill wires Implants/Bone plates Implants/Screws Titanium implants >> Current alloy surcharges >> Current scrap surcharges VERSIONS AND FORMS SUPPLIED Drawing From 2.0 mm to 28.0 mm round, tolerance zone IT 9 Min. bar length 2,000 mm Max. bar length 5,000 mm (2.0 mm to 6.0 mm round Max. bar...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Edelstahlzieherei Mark is traditionally a manufacturer of speciality products, whose uses also include medical equipment. To do justice to the high, specific demands on this product segment and this market, we have given these products a special status within the company. EZM offers EZM Chirusteel and EZM Chirutan products under the brand family name EZM Chiruline. In addition to placing special orders, customers can also fall back on medical grades and versions kept in stock. EZM Edelstahlzieherei Mark offers its customers in the medical equipment sector an extensive range of materials and versions – from stainless materials to titanium, and from ground round bars to sections. Drill wires Implants/Bone plates Implants/Screws Titanium implants >> Current alloy surcharges >> Current scrap surcharges VERSIONS AND FORMS SUPPLIED Drawing From 2.0 mm to 28.0 mm round, tolerance zone IT 9 Min. bar length 2,000 mm Max. bar length 5,000 mm (2.0 mm to 6.0 mm round Max. bar...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Edelstahlzieherei Mark is traditionally a manufacturer of speciality products, whose uses also include medical equipment. To do justice to the high, specific demands on this product segment and this market, we have given these products a special status within the company. EZM offers EZM Chirusteel and EZM Chirutan products under the brand family name EZM Chiruline. In addition to placing special orders, customers can also fall back on medical grades and versions kept in stock. EZM Edelstahlzieherei Mark offers its customers in the medical equipment sector an extensive range of materials and versions – from stainless materials to titanium, and from ground round bars to sections. Drill wires Implants/Bone plates Implants/Screws Titanium implants >> Current alloy surcharges >> Current scrap surcharges VERSIONS AND FORMS SUPPLIED Drawing From 2.0 mm to 28.0 mm round, tolerance zone IT 9 Min. bar length 2,000 mm Max. bar length 5,000 mm (2.0 mm to 6.0 mm round Max. bar...

Request for a quote

WEBER ULTRASONICS AG

Germany

Weber offers converters for all common frequencies (20 to 35 kHz) and power requirements (200 to 5,000 W). These converters are especially durable due to the Titanium-Aluminum alloy. Available as planar type together with matching booster or for direct Sonotrode attachment.

Request for a quote

EWG E. WAGENER GMBH

Germany

Titanium is a silvery-white light metal that is often found, but is difficult to extract. In its pure form titanium is easy to form, malleable, thermally relatively stable and very good electrical conductor. Important characteristics are its mechanical strength and low thermal expansion. Titanium is relatively resistant to air at room temperature and its corrosion resistance is comparable to that of precious metals. High-purity titanium is used as a getter metal to remove the last gas residues in vacuum technology, as it reacts with small amounts of oxygen. Corrosion-resistant, pure titanium is used in the construction of chemical plants. Due to their high strength, low weight and excellent corrosion resistance, titanium alloys are excellent construction materials for shipbuilding and the aerospace industry. Titanium is also an important alloying element in special steels.

Request for a quote

NIRO PRÄZISIONSTECHNIK GMBH

Germany

Niro Präzisionstechnik specializes in the manual mechanical processing of stainless steel thin sheets up to 4 mm. Our specialty are funnels, composite shapes, reductions and transitions, for example from round to square. All connections are welded while avoiding the inclusion of oxygen, and the weld seams are made invisible through careful polishing. The workpieces are machined free of tension and distortion with uniform wall thicknesses. We only process non-rusting materials such as V2A and V4A stainless steel, titanium alloys and aluminum. Our production conditions allow the manufacture of products for clean room applications such as those used in the pharmaceutical industry, medical technology and in the food industry. Suction devices Ring suction Downpipes Nozzles machine parts Assembly

Request for a quote

NIRO PRÄZISIONSTECHNIK GMBH

Germany

Niro Präzisionstechnik specializes in the manual mechanical processing and processing of thin stainless steel sheets up to 4 mm. Our specialty are funnels, composite shapes, reductions and transitions, for example from round to square. We only process non-rusting materials such as V2A and V4A stainless steel, titanium alloys and aluminum. Our production conditions allow the manufacture of products for clean room applications such as those used in the pharmaceutical industry, medical technology and in the food industry. Funnels and reducers from Ø 70 - 900 mm invisibly ground weld seams carefully smoothed transitions to avoid product buildup suitable for clean room applications uniform wall thicknesses free of tension and distortion

Request for a quote

WEBER ULTRASONICS AG

Germany

Weber uses FEM (finite elements method) to design Cutting Sonotrodes specifically for a customer or an application. These Cutting Sonotrodes are made from high-grade materials like Aluminum alloy, Titanium or sintered steel. Cutting Sonotrodes for the food industry are manufactured to precisely meet the required hygiene standards.

Request for a quote

WEBER ULTRASONICS AG

Germany

Weber uses FEM (finite elements method) to design Welding Sonotrodes specifically for a customer or an application. These Welding Sonotrodes are made from high-grade materials like Aluminum alloy, Titanium or sintered steel.

Request for a quote

FRIGORTEC GMBH

Germany

The POWDRYER™ PD08 metal powder dryer is used to dry inorganic metal powder for the complex additive manufacturing (3D printing) process. It corrects the manufacturer’s fluctuating metal powder qualities, thus optimizing the metal powder’s flowability. It also reduces the number of air inclusions in finished workpieces. Significantly higher material densities are the result. Fields of application > Particularly for metal printing products where maximum strength is required > For the printing of alloys of aluminium, titanium, tool steel, etc. > Special tools for the metal-processing industry, machine and system engineering, prototype development, and more > Aviation, aerospace, and automotive industries, plus medical and dental technology

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The HCS MULTI-FLUID is a series of carbide circular saw manufactured by Eisele. The key highlights of the HCS MULTI-FLUID series include a firm base frame that is welded, a bigger scope of cutting, an arbitrary saw blade that is accessible to ensure maximum cutting scope that can reach up to 180 mm . The machine has a sturdy and robust base frame on which the combined sawing unit and material feed unit are mounted. This structure combined with a very robust machine design ensures a smooth sawing process with excellent cutting results and a long service-life of the saw blade. The Multi-Fluid system is excellent for high-alloy stainless steels and tool steels, nickelbasedalloys like Inconel and Hastelloy as well as titanium alloys. Depending on the requirements, the following cooling/lubrication components can be combined in a most effective way: — Coolant nozzles for wet processing — Micro-spraying device for minimum quantity lubrication — Cooling vortex tube for dry cutting

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Titanium alloys • Metals with high residual stress • Stainless steels • Special alloys • Abrasive non-ferrous metals and graphite

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Stainless steel • Heat resistant steels • Cold and hot working steels • Hardened steel up to 1900 N/mm2 • Nickel based alloys • Aluminium-silicon alloys • Copper-nickel alloys • Titanium and titanium alloys • Exotic, hard to cut alloys

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • hard and tough materials up to 1700 N/mm2 tensile strength • Stainless steel • heat resistant duplex steel • nickel based alloys • aluminium alloys • titanium bades alloys

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Steels of the highest tensile strength • Long chipping materials • Stainless steel • Titanium based alloys • Nickel based alloys • Special bronzes

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Our compacting presses for titanium sponge are used in numerous dierent industries. Component parts made of titanium and titanium alloys play an important role in the aerospace industry for plane engines or highly stressed parts such as the undercarriage or supporting structures of an aircraft. Titanium is also indispensable for orthopedic applications as well as the chemical industry. The compression speed of our presses, which can be precisely adjusted to the product, oers operators highest repeat and size accuracy. Features Press capacity < 80 MN single or double-acting design automated tool change concept remote access for service support

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Our open-die forging presses play an important part among the forming presses. Siempelkamp supplies complete open-die forging presses equipped with manipulators and ancillary equipment such as lifting turntables and quite a number of additional components. Our presses operate reliably, fast and precisely, operating at pressing forces between 10 and 160 MN. The range of presses available comprise push-down or pull-down designs, two- or fourcolumn designs with oil-hydraulic or water-hydraulic drives. High-stroke frequency contributes to the eciency of these presses. Our customers produce bars, discs, rings, and anges from materials such as steel, high-alloy steel, nickel-based alloys, titanium, and aluminium on these presses. They prefer to order turn-key plants including integrated manipulators, turntable, die magazine, and die-changing system.

Request for a quote

ILS INNOVATIVE LABOR SYSTEME GMBH

Germany

Glass Barrel: Borosilicate 3.3 Precision: < ±1 % of the volume Main Use: - sample dosage for gas chromatography - HPLC-valves - autosamplers Plunger: - Nickel titanium alloy, flexible memory metal Removable Needle (RN) autoclavable Fixed Needles (FN) not autoclavable Needle Tip Needle Tip a b c d (FN) (FN) (FN) (FN) Length 51 mm 51mm 51 mm 51 mm Part Part Part Part Volume O.D. (Gauge) No. No. No. No. 5µl 0.47(26s) 2160301 2160302 2160303 2160304 10µl 0.47(26s) 2160401 2160402 2160403 2160404 Needle Tip a b c d (RN) (RN) (RN) (RN) Length 51 mm 51mm 51 mm 51 mm Part Part Part Part Volume O.D. (Gauge) No. No. No. No. 5µl 0.47(26s) 2160305 2160306 2160307 2160308 10µl 0.47(26s) 2160405 2160406 2160407 2160408

BÖLLINGHAUS STEEL GMBH

Germany

Stainless steel types: Austenitic Duples Ferritic Martensitic Nickel alloys Titanium

Request for a quote

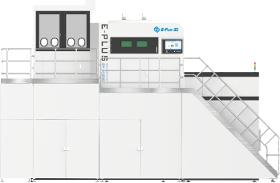

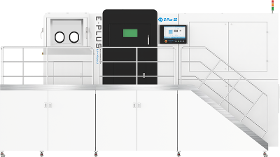

EPLUS3D TECH GMBH

Germany

EP-M150Pro adopts patented MPBF™(Metal Powder Bed Fusion)to produce high performance, high accuracy and high details parts at large scale. The machine is capable of optional single/dual laser system, and 200/500W laser source for different production requirements. The available materials are Aluminum alloy, Titanium alloy, Inconel alloy, Maraging steel, Stainless steel, CoCr, Copper alloy and so on.

Request for a quote

EPLUS3D TECH GMBH

Germany

With a building chamber size of 455*455*500mm Eplus3D Introduces EP-M450 to the successfulline of MPBF™ 3D printers. The complete open systemmakes EP-M450 a very powerful tool for large scaleproduction for our customer to access different metal powders like titanium, aluminum, nickel alloys and stainless steel, etc. EP-M450 is aiming to output the large parts with its high performance and high accuracy.

Request for a quote

EPLUS3D TECH GMBH

Germany

Using MPBF (Metal Powder Bed Fusion) technology, the EP-M1250 is using a 1258 x 1258 x 1350 mm3 build envelope and nine laser systems to ensure a high efficiency production. The precise positioning and innovative area splicing control technology offers uniformity and stability throughout the whole printing phase. The system can operate with various metal powders such as Titanium, Aluminum and Nickel-based alloys, Maraging Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is suitable for the direct manufacturing of largesize, high-precision and high-performance parts in the aerospace, aviation, automotive and machinery industry.

Request for a quote

EPLUS3D TECH GMBH

Germany

Using MPBF (Metal Powder Bed Fusion) technology, the EP-M650 is using a 655x655x800mm3 build envelope and quad laser systems to ensure a high efficiency production. The precise positioning and innovative area splicing control technology offers uniformity and stability throughout the whole printing phase. The system can operate with various metal powders such as Titanium, Aluminum and Nickel-based alloys, Maraging Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is suitable for the direct manufacturing of large-size, high-precision and high-performance parts in the aerospace, aviation, automotive and defense industry.

Request for a quoteResults for

Titanium alloys - Import exportNumber of results

25 ProductsCountries

Company type