- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- titanium alloys

Results for

Titanium alloys - Import export

WEBER ULTRASONICS AG

Germany

Weber uses FEM (finite elements method) to design Welding Sonotrodes specifically for a customer or an application. These Welding Sonotrodes are made from high-grade materials like Aluminum alloy, Titanium or sintered steel.

Request for a quote

WEBER ULTRASONICS AG

Germany

Weber offers converters for all common frequencies (20 to 35 kHz) and power requirements (200 to 5,000 W). These converters are especially durable due to the Titanium-Aluminum alloy. Available as planar type together with matching booster or for direct Sonotrode attachment.

Request for a quote

EWG E. WAGENER GMBH

Germany

Titanium is a silvery-white light metal that is often found, but is difficult to extract. In its pure form titanium is easy to form, malleable, thermally relatively stable and very good electrical conductor. Important characteristics are its mechanical strength and low thermal expansion. Titanium is relatively resistant to air at room temperature and its corrosion resistance is comparable to that of precious metals. High-purity titanium is used as a getter metal to remove the last gas residues in vacuum technology, as it reacts with small amounts of oxygen. Corrosion-resistant, pure titanium is used in the construction of chemical plants. Due to their high strength, low weight and excellent corrosion resistance, titanium alloys are excellent construction materials for shipbuilding and the aerospace industry. Titanium is also an important alloying element in special steels.

Request for a quote

WEBER ULTRASONICS AG

Germany

Weber uses FEM (finite elements method) to design Cutting Sonotrodes specifically for a customer or an application. These Cutting Sonotrodes are made from high-grade materials like Aluminum alloy, Titanium or sintered steel. Cutting Sonotrodes for the food industry are manufactured to precisely meet the required hygiene standards.

Request for a quote

FRIGORTEC GMBH

Germany

The POWDRYER™ PD08 metal powder dryer is used to dry inorganic metal powder for the complex additive manufacturing (3D printing) process. It corrects the manufacturer’s fluctuating metal powder qualities, thus optimizing the metal powder’s flowability. It also reduces the number of air inclusions in finished workpieces. Significantly higher material densities are the result. Fields of application > Particularly for metal printing products where maximum strength is required > For the printing of alloys of aluminium, titanium, tool steel, etc. > Special tools for the metal-processing industry, machine and system engineering, prototype development, and more > Aviation, aerospace, and automotive industries, plus medical and dental technology

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

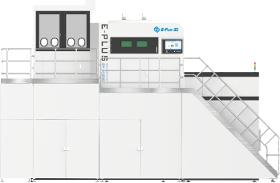

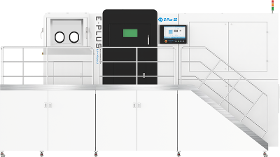

EPLUS3D TECH GMBH

Germany

EP-M150Pro adopts patented MPBF™(Metal Powder Bed Fusion)to produce high performance, high accuracy and high details parts at large scale. The machine is capable of optional single/dual laser system, and 200/500W laser source for different production requirements. The available materials are Aluminum alloy, Titanium alloy, Inconel alloy, Maraging steel, Stainless steel, CoCr, Copper alloy and so on.

Request for a quote

EPLUS3D TECH GMBH

Germany

With a building chamber size of 455*455*500mm Eplus3D Introduces EP-M450 to the successfulline of MPBF™ 3D printers. The complete open systemmakes EP-M450 a very powerful tool for large scaleproduction for our customer to access different metal powders like titanium, aluminum, nickel alloys and stainless steel, etc. EP-M450 is aiming to output the large parts with its high performance and high accuracy.

Request for a quote

EPLUS3D TECH GMBH

Germany

Using MPBF (Metal Powder Bed Fusion) technology, the EP-M1250 is using a 1258 x 1258 x 1350 mm3 build envelope and nine laser systems to ensure a high efficiency production. The precise positioning and innovative area splicing control technology offers uniformity and stability throughout the whole printing phase. The system can operate with various metal powders such as Titanium, Aluminum and Nickel-based alloys, Maraging Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is suitable for the direct manufacturing of largesize, high-precision and high-performance parts in the aerospace, aviation, automotive and machinery industry.

Request for a quote

EPLUS3D TECH GMBH

Germany

Using MPBF (Metal Powder Bed Fusion) technology, the EP-M650 is using a 655x655x800mm3 build envelope and quad laser systems to ensure a high efficiency production. The precise positioning and innovative area splicing control technology offers uniformity and stability throughout the whole printing phase. The system can operate with various metal powders such as Titanium, Aluminum and Nickel-based alloys, Maraging Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is suitable for the direct manufacturing of large-size, high-precision and high-performance parts in the aerospace, aviation, automotive and defense industry.

Request for a quoteResults for

Titanium alloys - Import exportNumber of results

10 ProductsCompany type