- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- working process

Results for

Working process - Import export

FESSMANN GMBH UND CO KG

Germany

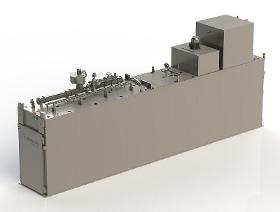

The TFi3000 Autovent is a true efficiencywonder! The patented procedure for lowpressure steam cooking without any fans at all, in combination with automated work processes, reduces the operating costs to a minimum. Cooling of the products in the closed system, directly subsequent to heat treatment, also ensures ideal hygiene conditions and increases durability. Production justintime, controllable process with reproducible work processes Automatic transport system Much lower germ formation and contamination – for longer durability Short cooking times and weight loss reduced by up to 15% Temperature difference across the system no more than 1 °C Uniform products at maximum quality due to turbulences and air velocities up to 200 m/s Very low maintenance and operation costs thanks to dispensing with fans Long service lives due to stainless steel construction and steamtight welding allround

Request for a quote

FESSMANN GMBH UND CO KG

Germany

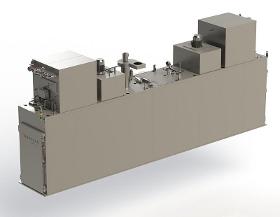

The semicontinuous TFi3000 for industrial use is not a compromise, but rather the combination of the benefits of two entirely different systems! It permits smoke, heat and cold treatments in a single production step. Automated work processes lower your operating costs while at the same time increasing production capacities. Efficient combination of Ti3000 & IKi3000 Production justintime, controllable and reproducible work processes Much lower germ formation and contamination – for longer durability Automatic transport system Producing, packaging and delivery in a very short time Lesser demand of cold storage capacities Higher trolley capacity as comparable floor conveyor systems by low construction

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Dry cleaning systems The dry alternative for cleaning Easy on the material & thorough Many years of experience with the working processes and requirements of our customers led us to develop an alternative cleaning system. The term alternative is appropriate, because in contrast to using conventional washing machines we have taken a completely different path. Whereas they work with wash emulsions everything remains dry on our cleaning system equipped with a linear brush unit – but it is just as thorough! Features & benefits • Clean coils/blanks economically without “washing agents” • Best cleaning performance • Rugged steel construction suitable for press shops • Low maintenance For all sheet metals and blanks Our dry cleaning system is suitable for material widths from 500-4500 mm. It cleans individual profiled sheets of metal, galvanised blanks, tailored blanks and much more. The system not only effectively removes interfering particles, but at the same time it also homogeniz

Request for a quote

SIKO GMBH

Germany

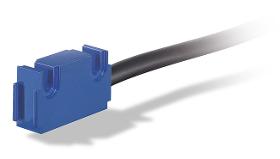

Incremental, miniature design, analog interface 1 V SS Profile LS100: Repeat accuracy max. ±1 μm Output circuit sin/cos 1 V SS Signal period 1000 μm (analog) Real-time signal processing Works with MB100/1 magnetic tape

Request for a quote

SIKO GMBH

Germany

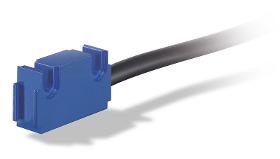

Repeat accuracy max. ±1 μm. Output circuit sin/cos 1 VSS. Signal period 1000 μm (analog). Real-time signal processing. Works with MB100/1 magnetic tape.

Request for a quote

KIRSCH KUNSTSTOFFTECHNIK GMBH

Germany

With our modern lathes and milling machines we can process thermoplastics according to the highest quality standards. We are using 3-axis as well as 5-axis milling machines. Example for our processing options: 3-axis machining up to a thickness of 80 mm and 1500 x 1000 mm format 5-axis machining up to a thickness of 700 mm and 2500 x 3000 mm format We manufacture according to provided drawings and CAD-data. Our programming stations are equipped with the latest CAD-CAM systems. Direct communication between job preparation and CNC work ensure a smooth process.

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

Dynamic Spur Gearboxes MS-Graessner produces customer-specific spur gearboxes of a helical or straight-toothed design. The design of the toothing is carried out using KISSsoft and our own design and calculation programs. In addition to the provision of technical support and advice to our customers, we also take over the entire engineering process. By working closely together with our customers, we guarantee the development and production of the optimum drive solution in each case. Advantages: economical production simple mechanical movement and power transmission high level of efficiency high running smoothness high axial and radial loads low circumferential backlash broad range of applications long service life

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

The Planetary Gearbox for Power and Precision Full power with the highest levels of precision. The PlanetGear has the necessary power reserves available for the most challenging power transmission requirements. Advantages: compact design high level of efficiency high torsional rigidity low mass moment of inertia torque high overload capacity high dynamics large transmission ratios MS-Graessner offers innovative, customised gearbox solutions in a helical or straight-toothed design. The design of the toothing is carried out using KISSsoft and our own design and calculation programs. In addition to the provision of technical support and advice to our customers, we also take over the entire engineering process. By working closely together with our customers, we guarantee the development and production of the optimum drive solution in each case.

Request for a quote

TOX-DÜBEL-TECHNIK GMBH

Germany

Features • Low effort and rapid processing • Especially for working with injection mortar cartridges • Ergonomic, non-slip handle • Sturdy, metal design • High quality alternative to the Profi model • Transmission ratio up to 1:18 Description & Area of Application • Guidance of the feed rod: The plastic in the core guarantees smooth gliding • Feed Plate: 2 thin metal layers with a plastic interlayer for problem-free dosing of the injection mortar • Riveted frame: Sufficient robustness to meet normal requirements • For the use of injection mortar with coaxial cartridges.

Request for a quote

FÖHRENBACH GMBH

Germany

The directly driven dividing apparatus of the TA3 series are excellent suited for the exact positioning of workpieces or, due to the high speeds, also for round machining of workpieces. The direct drive is absolutely backlash-free and ensures highest dynamics. All dividing apparatus are equipped with an automatic, pneumatically actuated clamping system. The dividing apparatus TA3G180 can be optionally equipped with an automatic hydrodehn clamping system (hydraulic expansion technology). Field of applications Rotation axis for angle positioning of work piece carriers in: Processing centers CNC - grinding machines Tool machines Laser processing machines, etc.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Programming is completely done in-house according to DIN EN 61131-3. The preferred programming languages used are either Siemens’ Step 7 or 3S’ CodeSys. The hardware depends on the application: it ranges from miniature control systems to computer solutions with connections to the office world in order to document the manufacturing process ideally. By working closely together with our customers we attain individual use of technological possibilities.

Request for a quote

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

Glasslifter for field assembly at construction side for windows and glass Windows and glass are expensiv and damageable. AERO-LIFT has developed the CLAD-LIFT to handle glass with care and save. Four seperate vacuum circles with four vacuum pumps holds the load save even if one seal of a suction plate ist defectiv. Functionality and features Vacuum lift for glass panes weighing up to 1000 kg, with off-grid power supply. Safety is ensured during the work process by a so-called quadruple circuit system. The redundant valves, suction plates and vacuum tank are used for controlling four separate suction circuits. The four suction circuits are monitored separately by the warning system and thus ensure full load-bearing capacity even in the event of a power outage. The glass lift is able to pick up and put down the panes both vertically and horizontally. Glass panes can be turned unrestricted 360°. Thanks to the battery power supply, the vacuum lift can also be...

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Ever-tighter safety regulations and extensive assembly times of a suitable working platform increase the complexity of service work on conical process vessels. For such requirements we have designed an intelligent solution: the customer-specific, modular working platforms for conical process vessels, such as reactors, orbital arm and screw dryers and conical mixers are secure, fast and easy to install. The platforms consist of a stable aluminum construction, are TÜV certified, CE-compliant and can be reused for many years. Their modular design enables installation via manway or other vessel nozzles. The individual modules have a low net weight and are easy to handle: The platform is securely fastened with just a few screws. Special rubber pads protect the vessel’s wall surface. Upon request, we provide working platforms with rescue hatches and any type of flaps – tailor-made to meet customer requirements. Additional features such as ladders are also provided.

Request for a quote

TAMPOPRINT GMBH

Germany

Without the pad printing process, the production of everyday objects such as decorated light alloy wheels, or even vital items such as insulin pens would not be easily possible. In doing so, TAMPOPRINT develops and works on process printing solutions across industry boundaries. Thus, there is no such thing as the typical TAMPOPRINT customer or the typical application. Rather, the fields of application are characterized by their diversity, their complexity and their individual characteristics. They range from the simpler printing of toys such as model trains, to the labeling of household appliances and beverage bottles, to highly complex processes such as the micrometer-accurate labeling of medical products, e.g. insulin pens and laboratory tubes. Even the particularly challenging direct application of active pharmaceutical ingredients onto a carrier material, such as in nicotine patches, can be implemented thanks to the TAMPOPRINT solutions.

Request for a quote

OPTIMA PHARMA GMBH

Germany

Gently objective handling Simple operation Continuously working Processability of all commercial closures Small amount of format parts Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

KRAMSKI GMBH

Germany

Our core technologies, precision stamping and hybrid technology, are complemented by our special processes (parts cleaning, tumbling, brushing, sand blasting, polishing, laser marking, tape-and-reel, and more). Here, it is all about know-how-intensive processes and work steps, which we specifically use to improve the quality of our products and to hold our promise of KRAMSKI quality in every way.

Request for a quote

SNK GMBH

Germany

・Rigid structure with a flat, wide beds built for heavy cutting ・High-precision headstock with thermal balance function ・Adjustable control panel for operator convenience ・Ideal for a wide variety of turning processes ・Large diameter built-in center standard on tailstock. ・Ideal for long work processing with various follower rest attachments ・Maximum Swing Diameter: 1,600mm – 2,500mm (standard); up to 4,000mm ・Center Distance: 6,000mm (standard); customizable ・Workpiece Capacity: 70,000kg (standard); up to 400 Tons

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

Using TAPTITE 2000® ensures that in metal-joining applications, you can eliminate work processes such as tapping and the use of additional fastening elements. The fastener is screwed straight into a cast or drilled core hole. The polygonal cross-section geometry of the shaft of the screw ensures that the thread is chiplessly formed, so that if a repair is needed it can accept a conventional threaded screw. This provides some significant quality advantages: easy to position the screw low tapping torque high vibration resistance high vibration resistance high pre-load forces high assembly reliability Your commercial benefits: The overall cost of fastenings is reduced by up to 88%.

Request for a quote

ASSFALG GMBH

Germany

These magnets can be individually adjusted to different tasks. They are only switched on with a short compressed air impulse between 5 and 8 bar. They are low-maintenance and have very fast switch-on times. Individual solutions with multiple parallel-controlled magnets simplify your lifting task or work process. It is not just used in fully automatic systems, but rather also for the simples manual lifting processes.

Request for a quote

ASSFALG GMBH

Germany

These magnets can be individually adjusted to different tasks. They are only switched on with a short compressed air impulse between 5 and 8 bar. They are low-maintenance and have very fast switch-on times. Individual solutions with multiple parallel-controlled magnets simplify your lifting task or work process. It is not just used in fully automatic systems, but rather also for the simples manual lifting processes.

Request for a quote

ASSFALG GMBH

Germany

These magnets can be individually adjusted to different tasks. They are only switched on with a short compressed air impulse between 5 and 8 bar. They are low-maintenance and have very fast switch-on times. Individual solutions with multiple parallel-controlled magnets simplify your lifting task or work process. It is not just used in fully automatic systems, but rather also for the simples manual lifting processes.

Request for a quote

ASSFALG GMBH

Germany

The AY series was developed specifically for sheet handling. They can measure technically with vacuum systems in the thin sheet area and are much more efficient. They are only switched on with a short compressed air impulse between 5 and 8 bar. They are low-maintenance and have very fast switch-on times. Individual solutions with multiple parallel-controlled magnets simplify your lifting task or work process. It is not just used in fully automatic systems, but rather also for the simples manual lifting processes.

Request for a quote

ASSFALG GMBH

Germany

The AR series was specifically designed for workpieces that do not have any level contact surfaces. They are only switched on or off with a short compressed air impulse. Workpieces with level, flat, round or irregular surfaces are transported without effort. Individual solutions with multiple parallel-controlled magnets simplify your lifting task or work process. The magnets are only switched on with a short compressed air impulse between 5 and 8 bar. They are low-maintenance and have very fast switch-on times. It is not just used in fully automatic systems, but rather also for the simples manual lifting processes.

Request for a quote

ASSFALG GMBH

Germany

The circular trough vibratory finishing machines are ideal for small and large series for different workpieces. A noise protection cover reduces the noise and makes it possible to work in a workshop. The right and left-hand circulation as well as speed regulation from 1,200 to 1,500 rpm provide for various processing possibilities. The abrasive material and workpieces are rotated through the generated vibration. The desired processing process is created through the contact of grinding bodies on workpieces. The programmable timer rounds off the autonomous work process. We recommend a paper filter or a fully-automatic water treatment plant for simple and comfortable water treatment. The integrated separating equipment simplifies the separation of grinding bodies and workpieces.

Request for a quote

ASSFALG GMBH

Germany

The centrifugal plants are suitable for small parts. Due to the higher machining intensity with deburring, they deburr 10-20 times faster than vibratory finishing machines. The centrifugal plant can be planned as a single device up to a fully automatic plant. The grinding bodies and workpieces are accelerated through the rotational movement of the plate washer. Due to the centrifugal force, the workpieces are pressed outward and then transported up on the inner side of the system. Gravity causes these to fall back into the center of the plate washer to be accelerated again. A noise protection cover reduces the noise and makes it possible to work in a workshop. The speed regulation ensures versatile processing options. The programmable timer rounds off the autonomous work process. The machine can be expanded with an optional paper filter and separator.

Request for a quote

ASSFALG GMBH

Germany

The trough vibratory finishing machines are ideally suited for elongated individual parts and small series. Their advantages lie in the machining of heavy, bulky as well as long workpieces and in the contact-free working of sensitive individual parts in chambers. A soundproof cover reduces the noise level and makes working in a workshop possible. The clockwise and anti-clockwise rotation as well as the speed control from 1,200 to 1,500 rpm ensure a wide range of machining options. The unmanned working process is rounded off by the programmable timer. The system can be expanded with an optionally available paper filter and separator. For simple and convenient water treatment, we recommend a paper filter or a fully automatic water treatment system. The process water is pumped into the trough in doses and cleaned in the return flow via a filter fleece or the centrifugal force.

Request for a quote

ASSFALG GMBH

Germany

The tub vibratory finishing machine, which has a size similar to a washing machine, with a fill volume of 70 l is our standard machine and is ideal for prototypes and small series. A noise protection cover reduces the noise and makes it possible to work in a workshop. The right and left-hand circulation as well as speed regulation from 1,500 to 3,000 rpm provide for various processing possibilities. The abrasive material and workpieces are rotated through the generated vibration. The desired processing process is created through the contact of grinding bodies on workpieces. The programmable timer rounds off the autonomous work process. The machine has a modular construction and can be expanded with an optional paper filter and separator. Both are controlled centrally through the control panel on the TV 95-SL. We recommend the PF440 paper filter for simple and comfortable water treatment. The S95 separator simplifies the separation of grinding bodies and workpieces.

Request for a quote

ASSFALG GMBH

Germany

The SMA 20-A series is available in an electrical or compressed-air operated design. The machine is designed for handling steel, aluminum, copper and plastics. A chamfer width of up to 7 mm is possible in NE metals and a chamfer width of up to 4mm in steel. In addition to this, a radius processing of 1.2mm and 2.5mm is feasible. The stunning and patented 8 or 16 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The processing of drill holes is already possible starting at a diameter of >20mm.

Request for a quoteResults for

Working process - Import exportNumber of results

29 ProductsCompany type

Category

- Finishing of surfaces - machinery (4)

- Internal transport systems (4)

- Magnetic equipment (4)

- Cooking and smoke-curing equipment for delicatessens (2)

- Mechanical transmission - components (2)

- Milling - machine tools (1)

- Pharmaceutical industry - machinery and equipment (1)

- 3D scanner (1)

- Cutting - machine tools (1)

- Engineering - industrial contractors (1)

- Fastening devices (1)

- Lifting equipment - accessories (1)

- Metalworking - portable power tools (1)

- Pad printing (1)

- Sensors (1)