- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- touch panel

Results for

Touch panel - Import export

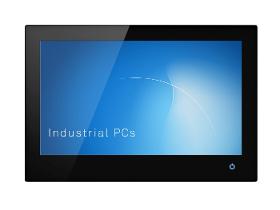

ADS-TEC INDUSTRIAL IT GMBH

Germany

The fanless built-in panel PCs of the OPC9000 series set new standards in terms of user-friendliness. More flexibility in process design in production environments. In addition to the on/off button on the rear, the industrial PC from the OPC9000 series has a newly designed capacitive on/off button on the front, which can be operated via software. Thanks to the innovative mounting system, it can be installed quickly and easily in any machine or system without the need for special tools or separate mounting parts. The built-in 8th generation Intel® processors ensure seamless human-machine interaction. To connect additional fieldbus protocols, the OPC9000 models can be equipped with a Hilscher netJack module.

Request for a quote

HERBERT WALDMANN GMBH & CO. KG

Germany

The adjustable ALD arm-mounted luminaire appeals for its flexible head joint and balanced arm. The wide area of illumination of the work area and option of continuous dimming ensure ergonomic working, even for activities that take a long time. Plus the ALD is suitable for use in all kinds of industrial environments. — LED technology — Colour temperature neutral white 5000 K — Colour rendering Ra > 80 — Glare-free thanks to structured cover — Housing made of colourless anodised aluminium and grey plastic — Polycarbonate plastic screen — Ergonomic arm-mounting technology with 3D head joint — Touch panel in luminaire head for On / Off and dimming — Degree of protection IP20; protection class I — Supplied with approx. 3 m connecting cable and plug-in power supply with plug type CEE 7/16 (Europlug), BS 1363 and NEMA 1-15P — Various fasteners as accessories

Request for a quote

SERVOLIFT GMBH

Germany

SERVOLIFT laboratory blenders are ideal for producing small batches under production conditions. This is possible through the container’s geometry, which is adapted from the large production blender. The knowledge gained from blending tests creates a reliable basis for later manufacturing. Parameters such as RPM and time can therefore be varied. Small size - large effect Technical description Compact blender, ideal for product and process development Operate on a control or touch panel Design and geometric relationships correspond to the large production blenders Also available as test and loan unit

Request for a quote

MOSCA GMBH

Germany

• SoniXs Ultrasonic sealing unit • Strap dispenser • Complete electric control for automatic and semiautomatic operation in the operator panel • Siemens PLC control with touch panel • Different Models: [KZV-311] • Lateral mounted sealing unit • Sealing unit moveable towards the product • Strap lance for strapping of palletised goods [KOV-311] • Like basic model KZV-311, closed strap frame for boxes and cartons

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

The new POWER CHARGER units cover various performance stages and charging applications. They can be operated either with a supply voltage of 24 V DC or a line voltage in the range of 85 V – 264 V AC. The output voltage is 75 or 150 watts. A membrane keyboard or an optionally available, integrated touch panel is used to control the generators. POWER CHARGER units can be operated using analog operation or via digital fieldbus interfaces. A control system that uses CANopen and ModbusTCP and other fieldbus standards are available.

Request for a quote

MOSCA GMBH

Germany

Inline strapping parallel to flute Thermostatically controlled heat-weld sealing Siemens PLC control with touch panel 5-sided electromechanical package alignment Potential-free contacts to upstream and downstream machines Automated setup system resets to the dimensions of the first bundle of the new size (“Teach-In”) Capability to strap up to 90 mm outside the bundle center (adjustment in steps of 10 or 30 mm) allows for perfect strapping of complex bundle sizes and forms Chassis on rails with mechanical locking [MCB-2 XT]: Two movable sealing units

Request for a quote

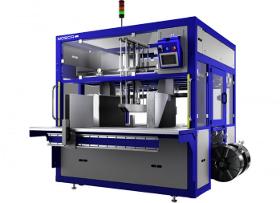

EMAG ELDEC INDUCTION GMBH

Germany

eldec brazing systems: automatic induction brazing of pole coils The semi-automatic equipment is designed for manufacturing pole coils of hydro and wind power generators. The machine is based on the experience of the previous manufactured equipments. The machine is designed as a sturdy, high quality and low maintenance machine. The operating is very simple, on automatic mode by 2-hand operation with step by step program and on manual mode by touch-panel.

Request for a quote

MOSCA GMBH

Germany

KKOV 315, Basic Model Laterally friction-weld sealing Height moveable, horizontal arch Sealing unit, moveable laterally to the package PLC control Operation via 7" touch panel 10 freely configurable programs with up to 10 strapping positions Can be integrated into most production lines Potential-free contacts to upstream and downstream machines KOB 315, Special Version Like basic model KOV 315; additionally equipped with 2-side aligning device KOH 315, Special Version Like basic model KOV 315; additionally equipped with 4-side aligning device Options: SoniXs Ultrasonic sealing system Vertical edge protection applicator Three-part signal light including low strap indication Air conditioning equipment Strap sealing unit BSG 4 Data interface KSR-2 DC sealing unit HL sealing unit with floating head Design with operator button in addition to touch panel Structural colour according to RAL-scale

Request for a quote

MOSCA GMBH

Germany

• Inline strapping parallel to flute • SoniXs Ultrasonic needle sealing unit • Automated setup system resets to the dimensions of the first bundle of the new size [Teach-In] • 6-sided electromechanical package alignment • Potential-free contacts to upstream and downstream machines • Siemens PLC control with touch panel • Stand-by-mode reduces wear and energy consumption • Lateral automatic adjustment device • Automatic machine adaptation to package dimensions via adjustable recipes [500] • Sealing unit removing device

Request for a quote

MOSCA GMBH

Germany

• SoniXs Utrasonic sealing unit in standard-6 version • High availability due to controlled frame • 5-sided electromechanical package alignment • Continuously adjustable conveyor speed • Laterally driven transport belts • Driven top belts • Electro-mechanical package stop and hold-down device • Intuitive user guidance via colored touch panel with ergonomic positioning options • ATR – Automatic cycle rate regulation • Easy maintenance due to automatic removable strapping unit • Automatic machine adaptation to package dimensions via adjustable recipes • CE marking inclusive conformity declaration

Request for a quote

MOSCA GMBH

Germany

Ultrasonic sealing system with electronic self-calibration High-end Standard 6 sealing unit Dispenser variably mountable Intuitive user guidance via colored touch panel Electromechanically driven aluminum rollers ensure an optimal product transport Continuously adjustable conveyor speed from 0.2to 1.0m/s Bundle positioning via increments by metrical input of the strapping positions Open design without protective coverings - CE marking inclusive conformity declaration Infeed side guidance Extremely low energy consumption

Request for a quote

TAMPOPRINT GMBH

Germany

High requirements are the core competence of the RAPID machine series. At home in the construction of automated systems with very high performance requirements. An energy-efficient electromechanical drive with extremely quiet running for precision designed printing motifs will guarantee your additional benefit. The User-friendly touch panel offers a number of setting options and makes it possible to coordinate the machine exactly to your customer-specific task. The RAPID series is available with useful, practical and additional extensions for individual configurations.

Request for a quote

MOSCA GMBH

Germany

• Top-mounted SoniXs ultrasonic sealing unit • Automatic height adjustment of pressure plate to bundle height • Easy accessibility • Electrically driven lift plate with geared brake motor • Strap dispenser • Siemens PLC control with touch panel • 2-column design from 2,200 mm passage width Different Models: [KZV-111] • Top-mounted sealing head • One SoniXs- sealing head and one vertical strap guide • Movable strap lance for strapping of palletized goods [KZS-111] Like basic model KZV-111, with laterally moveable turntable [KOV-111] Like basic model KZV-111, with additional underfeed channel for unpalletized goods [KVV-111] Like basic model KZV-111, bottom arch with automatically controlled strap lance or underfeed channel; particularly suitable for strapping of frequently changing package types with or without pallets Options: • Automatic balk feeder with large buffer [KOV] • Angle edge protection for securing sensitive products for transport [KOV]

Request for a quote

MOSCA GMBH

Germany

• SoniXs Ultrasonic sealing unit in standard-6 version • Strapping applied in transport direction without bundle turning • Easy accessibility and tool-free dismantling of strap path components • Potential-free contacts to upstream and downstream machines • Infinitely adjustable conveyor speed from 0.1 to 1.0 m/s • Optimization of the strapping processes by machine adaptation to defined package dimensions • Energy-efficient, electro-mechanical hold-down device (also available as pneumatic version) • CE marking inclusive conformity declaration • Extremely low energy consumption [Base] • Easy operation over digital display in the control panel [Pro] • Intuitive user guidance via colored touch panel; division into different user groups

Request for a quote

MOSCA GMBH

Germany

• Top-mounted SoniXs ultrasonic sealing unit • Up to four strap lances for palletized products • Strap guide distance of 440, 625 and 810 mm • 1 or 2 sealing units laterally movable • Siemens PLC control system • Operation via Siemens 9” touch panel • Can be integrated into any production line • Potential-free contacts to upstream and downstream machines • Strapping with medium compression [up to 30,000 N – version KC_] • Strapping with high compression [up to 50,000 N – version KP_] Different Models: [K_R] Basic Model \ Driven roller conveyor [K_K]-Version \ Driven roller conveyor with lift turncross [K_Z]-Version \ Driven roller conveyor with centering device [K_A]-Version \ Driven roller conveyor with lift turncross and centering device [K_T]-Version \ Driven roller conveyor with turntable [K_S]-Version \ Driven roller conveyor with turntable, laterally moveable

Request for a quote

MOSCA GMBH

Germany

• SoniXs Ultrasonic sealing unit in standard-6 version • Potential-free contacts to upstream and downstream machines • High sealing tension due to a minimum distance from package to sealing unit • Programmable control with panel inclusive manual control with functional sequence of strapping control • Adjustable strap tension via touch panel • Low-wear, controlled strap path system • Stroke of strap guide frame via belt drive • Strap end detection with ejection of remaining strap • Wear-free DC drive, brushless motor technology • 10 freely configurable programs with up to 10 strapping positions

Request for a quote

TAMPOPRINT GMBH

Germany

The SEALED INK CUP 90 Q is a single-color pad printing machine for the realization of oblong print images that are larger than the ink/doctoring cup used. Designed as an entry-level model, this machine offers a good basis for a variety of applications. As basic equipment this pad printing machine contains a base frame with practical storage space. This also ensures a stable stand and leads to high stability. Flexibility is provided by the height-adjustable angle table, which allows quick changeover to components of different sizes. With the user-friendly touch panel many machine parameters and functions can be controlled and set on the display.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Touch panel - Import exportNumber of results

18 ProductsCompany type