- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- testing equipments

Results for

Testing equipments - Import export

DÜRR NDT GMBH & CO. KG

Germany

Portable high resolution CR scanner for all NDT radiography applications - weld inspection, profile images and aerospace Unique 30 μm basic spatial resolution – BAM-certified Scans flexible imaging plates up to 35 cm in width Widest range of applications thanks to TreFoc Technology Intuitive handling & easy transition from film Portable and compact (17.5 kg) What does TreFoc Technology mean and how does it work? TreFoc Technology is the name for the our new laser focussing technology, uniquely in systems from DÜRR NDT. With TreFoc the laser beam is adjusted perfectly to give optimal image results and the highest signal-to-noise ratio in any application. Inside the laser tube, an iris diaphragm adjusts the laser beam diameter. Since the perfect laser beam diameter can be selected for each object and image type, optimum results for any particular application can be easily achieved. Regardless of the application – high-resolution image or low-exposure c

Request for a quote

WEINLICH GMBH & CO. KG

Germany

Transportable engine supports minimize the times of standstill of the engine test bed, as the engines can be built up and tested separately. The mounted engines can be coupled to the engine test bed quickly and without any effort. RWB mobile operation trolleys and Universal Engine Supports may be used with MP dynamometers and with other suitable dynamometers (by Weinlich or other manufacturers). Their modular design allows interchangeability and reusability. RWB are mobile thanks to swivel rollers. They have a load capacity of max. 800 kg. A RWB mobile operation trolley has a low base frame from which single supports lead up to the fixing points of the engine. By this design all parts of the engine can be reached as well as possible. Thanks to its solid and proven construction the mobile operation trolley is nevertheless able to match up to the stress during power tests. Universal Engine Supports have a higher load capacity (1000 kg and 2000 kg) than RWB. ...

Request for a quote

WEINLICH GMBH & CO. KG

Germany

Two kinds of fuel are changed in the engine repeatedly without mixing. Thus also small differences in the specific consumption, the emissions and further values measured at the engine which are influenced by the fuel will be clearly visible. The engine is charged by a coupled braking dynamometer (engine test bed). At the test bed, different load conditions may be adjusted. The reproducibility of the experiments is secured by the speed stabilisation and the automatic gravimetric determination of the specific fuel consumption of the MP Computer. Example of application: Testing the efficiency of fuel additives or of other kinds of fuel pretreatment.

Request for a quote

WEINLICH GMBH & CO. KG

Germany

- self-supporting bed, - no transfer of torque to the ground - rapid fixation of modules and additional equipment in any axial position without drilling Picture: The modules executing torque on each other consist of electric motors with a high torque transmission. They are secured by strong clamping elements on the test bed. Their axial position is adjustable. The removable protection grid protects only against accidental contact to rotating parts under laboratory conditions. Solid axially movable protection covers are avaiable if parts might detach and fly away.

Request for a quote

WEINLICH GMBH & CO. KG

Germany

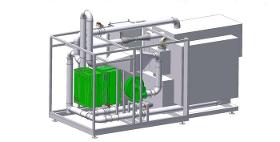

For Example: Container 40 ft for outdoor installation for performance testing at combustion engines with all kinds of dynamometers. Depending on the kind of the installed dynamometer, external supply beyond electricity (e.g. for cooling water) will be required. Thanks to our mobile engine supports, there is no need of an overhead gantry crane or any other lifting device.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

With the purge air method, heat recovery for balanced air mass flows can be determined for alternating, decentralised ventilation units. The uncertainties of the direct measuring method used so far due to inhomogeneous velocity and temperature profiles at the outlet of the ventilation units are circumvented by the scavenging air method and the measuring accuracy is higher. With the optional humidity conditioning the moisture recovery can also be determined. Further thermal performance indicators are the air volume flow in alternating operation and the balance, which can also be determined with the test bench. The test stand is equipped with an auxiliary fan so that continuously operating ventilation units can also be measured with the direct measuring method.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

Based on years of experience in the field of test bench metrology in the automotive industry, EP develops test bench solutions for various applications. We build test benches for testing automotive components such as heat exchangers, intercoolers, filters, valves and others. These are test benches on which e.g. supplier parts for the automotive industry are tested in production. Our specialist knowledge of the industry makes us a strong partner in this area.

Request for a quote

DATAPHYSICS INSTRUMENTS GMBH

Germany

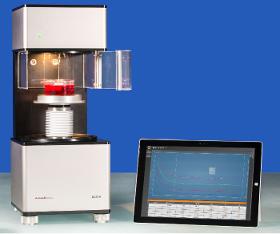

The tensiometers of the DCAT series are measuring instruments for force-based investigation of surface and interface properties. Because of the compact and modular product design of the DCAT series, a bespoke combination of device and accessories can be found for any use case. The DCAT 9 is the powerful entry-level model of the product series. It allows the measurement of surface and interfacial tensions as well as the determination of the density of solids and liquids. Possible measurements: - surface and interfacial tension - density of solids and liquids

Request for a quote

DATAPHYSICS INSTRUMENTS GMBH

Germany

The optical contact angle meters of the OCA series are high-precision measuring systems for the characterisation of interfaces and surfaces. They combine high-resolution optics, pinpoint liquid dosing and precise sample positioning to create powerful, reliable measuring systems. The entry-level model OCA 15EC enables basic methods of professional contact angle measurement and drop shape analysis. Thanks to the modular construction, even this entry-level model can be combined with many accessories, such as the TBU 100EC tilting unit. Possible Measurements: - static contact angle - dynamic contact angle - interfacial/surface tension - surface energy - viscoelastic modulus - work of adhesion

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

For checking the gas detection and gas measuring devices. All gases can be connected in 12 liter aluminum pressurized gas cans.

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test gas set for testing gas detection and gas measuring devices GPL and GPD. According to the DVGW rules, a weekly check with 1 vol% CH4 is necessary. With screw-on extraction adapter and display of the flow. Delivered with conditioning filter in a carrying case (not including GasPen).

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

You can find the gas concentration needed for each device in the user's manual. There are additional costs for shipping by air freight. We recommend using the test gas set or a sampling valve.

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station for checking the gas detection devices according to G465. The control of the minimum sensitivity (10ppm) and the control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 are possible. All gases can be connected to 1 liter aluminum compressed gas cans. The remaining pressure of the bottle is always displayed. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. Rather than a pressure gauge, the PS 403-US has a vacuum manometer. In the PS 403-US model, the control buttons are replaced by toggle switches. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station for revising gas detection devices. The control of the minimum sensitivity (10ppm) and the control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 are possible. All gases can be connected to 1 liter aluminum compressed gas cans. The remaining pressure of the bottle is always displayed. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. Rather than a pressure gauge, the PS 403-U has a vacuum manometer. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station for checking the gas detection devices according to G465. The control of the minimum sensitivity (10ppm) and the control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 are possible. All gases can be connected to 1 liter aluminum compressed gas cans. The remaining pressure of the bottle is always displayed. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station to review the gas detection devices. The control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 is possible. All gases can be connected to 1 liter aluminum compressed gas cans. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station for checking the gas detection devices according to G465. The control of the minimum sensitivity (10ppm) and the control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 are possible. All gases can be connected to 1 liter aluminum compressed gas cans. The remaining pressure of the bottle is always displayed. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. With flow measurement. The test gas is conditioned (humidified)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZWICKROELL GMBH & CO. KG

Germany

The HIT series offers pendulum impact testers for plastics. They are specifically designed for manufacturing and processing plastics. Designed with an accurate and reliable structure, these instruments are configured in the right range according to standards of use. They make use of carbon double rods for the pendulum and are capable of providing maximum stiffness in the impact direction. These pendulum impact testers deliver optimum concentration of masses at a specific point of impact. A single pendulum is integrated with a fast-change device therefor allowing faster, zero-tool pendulum changes. The HIT series are characterized by their easy to operate system and ergonomically built controls. Typical tests: - Charpy tests: ISO 179, ASTM D6110 - Izod tests: ISO 180, ASTM D256, ASTM D4812 - Impact tensile tests: ISO 8256 Methods A and B, ASTM D1822 - Dynstat bending and impact tests: DIN 53435

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

ZwickRoell`s HDT/ Vicat all round instruments have been designed in a manner that enables them to be convenient for testing in research and development, inwards checks of goods, monitoring of production and also in education and training. Versions with up to 6 testing stations can be made available. The instruments include measuring stations which can be lowered in an automatic manner and then there is the optional test-weight lowering. The optional re-cooling device is able to reduce the oil re-cooling time as a result of which high test-rates are a possibility. The advantages included here are that the tests possible to the standards of ISO 306, ASTM D 1525, ISO 75 and ASTM D 648. Key Advantages and Features: - Measuring station lowered automatically - Optionally available automatic test-weight lowering - Optional internal re-cooling device for rapid attainment of starting temperature - Testing to ISO 306, ASTM D1525, ISO 75 and ASTM D648.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

laserXtens Array HP features a measuring head incorporating seven fixed high-resolution cameras. The overlapping fields of view of the seven cameras are combined into a single large image, giving a very large measuring range.Advantages of laserXtens Array - laserXtens Array HP possesses an extremely large measuring range, combined with a resolution of 0.10 μm. - laserXtens Array HP has no moving parts and is completely maintenance-free. - laserXtens Array HP satisfies the requirements of Class 0.5 of ISO 9513 (Class B2 of ASTM E83). - Used for strain-rate-controlled tests to ISO 6892-1 Method A1 (closed loop) for gage lengths from 30mm. Different gage lengths can be set in fractions of a second. laserXtens Array HP can also measure transverse strain with no need for additional markings; biaxial measurement is additionally possible. Determination of strain distribution and strain at break as per Annex H of ISO 6892-1

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

With a maximum impact speed of 4.4 m/s and a drop weight of 23,5 kg, this drop weight tester is ideally suited for puncture tests to ISO 6603-2. A standout feature is the excellent test area accessibility, enabling rapid completion of test series including direct feeding of temperature-conditioned test plates. This drop weight tester is unbeatable when it comes to efficiency and operator-friendliness. Range of application: The Amsler HIT230F is ideally equipped for multiaxial impact puncture tests on plastics. Its range of application includes material characterization of standard specimens in accordance with established standards in research and development and quality assurance. • Multiaxial impact puncture tests to ISO 6603-2, ASTM D 3763, at room temperature and in extended temperature range.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The HB Servo-Hydraulic Testing Machine is specifically designed to provide an excellent quality performance and functionality. It is a high quality device which is built with a testing actuator mounter on top of the cross head. The superior quality apparatus is considered as a very versatile device to be used especially in conjunction with the T-slotted platform which allows flexure tests and component testing in addition to several fatigue tests. It is also available in a wide a range of versions for test loads from 50 to 2500 kN. The standard testing actuator stroke of 100, 250 or 400 mm. It can be supplied for 210 or 280 bar system pressure. The test frame features extremely high stiffness and natural resonance. Advantages and features • testing actuator mounted on upper crosshead • hydraulic clamping and adjustment for easy positioning of upper crosshead • comprehensive range of accessories, including hydraulic grips, compression platens, flexure test kit etc.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The zwickiLine testing machine is equally ideal for research and development as it is for routine quality assurance testing. Development and manufacture of the zwickiLine, including all mechanical, electronic, and software components—together with the comprehensive range of accessories — takes place at ZwickRoell's production facility in Germany, so all components work together seamlessly. Your benefits: - load range from 500 N up to 5 kN and with test-area heights from 565 mm to 1365 mm - Low weight, a small footprint and space-saving design - Suitable for tensile, compression, flexure and bending tests on different materials and components - Wide range of specimen grips and testing tools

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

A new dimensionThe ZHN universal nanomechanical tester is used for comprehensive, mechanical characterization of thin layers or small surface areas with the necessary force and travel resolution. This includes measuring indentation hardness, indentation modulus, and Martens hardness to ISO 14577 (instrumented indentation testing). Key Advantages and Features - Modern software, with clearly structured design - Stiff frame design with indenter axis exactly in the movement axis (no tilting moment) - High degree of modularity ZHN Applications: - Hardness and Young´s modulus to DIN EN ISO 14577 - Vickers hardness - Micro ear tests - Scratch and micro-scratch tests

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The ideal system for individual testing situations and all applications. AllroundLine can be used for applications from all areas. A proven operating concept combined with flexible, modular load-frame design makes the AllroundLine an optimum solution for demanding testing applications, whether for quality control or for research projects. Development and manufacture of AllroundLine, including all mechanical, electronic, and software components—together with the comprehensive range of accessories—takes place at ZwickRoell's production facility in Germany, so all components work together seamlessly. Typical tests: - tensile test on metals (eg ISO 6892, ASTM E8), plastics (ISO 527), composites, rubber, ... - bending tests - flexure tests - shear tests - components tests

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The ZHU 250 is ideally designed to promote an excellent quality performance and functionality. It is built with an attractive and sophisticated structure used for a very simple and easy operation, direct-viewing and more. It is considered as a versatile tester used for process loading, dwelling and unloading of the test force. It is also constructed with three hardness testing methods specifically the Brinell, Rockwell and Vickers for further variation. It is a fully automated test sequence and a highly accurate closed-loop drive system, together with excellent depth of field. The RS232 connection to testXpert® testing software enables all tests to be evaluated and documented and data transferred to quality assurance systems for further processing. The custom-made accessories tailored to a wide range of applications are also provided.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The ZwickRoell 3105 Combi Test machine is a hardness tester that is controlled by a microcomputer. This unit is characterized by a highly accurate measurements in several IRHD and shore measurement ranges. This device eradicates the operator related errors due to having a fully automatic and digital measurement system across all Shore and IRHD ranges. This unit is also compatible with services that are concerned with sheet materials like performing an automatic test sequence. It has an indenter that scans the surface of the item before the spring generated load is applied.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The ZHU/Z2.5 is the most versatile and flexible hardness testing machine in the world, it has a zwickiLine testing machine with a hardness measurement head which contains a digital travel-measuring system and an exchangeable indenter with sensor foot. It can be used with all ZwickRoell Materials testing machines and in automated applications. All indentation depth measurement method hardness tests, including Martens hardness HM, Rockwell hardness, and ball indentation hardness can be performed. Vickers depth measurement HVT, Brinell depth measurement HBT, and Knoop tests can be performed with an optical unit accessory attached to the head. This unit contains a measuring microscope and a linear displacement component, which allows the microscope and load unit to exchange positions without the need to move any components under test.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The HT1000 and HT2000 have many applications in the primary metals, metal fabrication, utilities, petroleum, chemical, automotive and aerospace industries. Their small size and easy to use, one-handed operation, makes them ideal for testing large and heavy forgings or castings, such as steel mill rolls and turbine housings. Due to their small size and portability, the testers can be used to test individual parts of a large assembly without taking the finished assembly apart. The testers can be used in any direction, and require only a small surface area to obtain a quick and accurate reading.

Request for a quoteResults for

Testing equipments - Import exportNumber of results

63 ProductsCompany type

Category

- Testing equipment (38)

- Measurement and control instruments (7)

- Pneumatic systems and tools (6)

- Engine testing and regulating equipment - electronic (3)

- Non-destructive tests (3)

- Electrical & Electronic Components (2)

- Radiology equipment, industrial (2)

- Ballistic equipment and testing (1)

- Testing of products and materials (1)

- Bearings, roller (1)

- Foundries - machinery and installations (1)

- Heat exchangers (1)

- Measurement and regulation equipment and instruments - electricity and other energy (1)

- Optical measuring equipment (1)