- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- process development

Results for

Process development - Import export

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

Paints and coatings, sealing and insulating materials, coatings, chocolate masses, dairy products, personal care and many other products are produced on process systems from our company. The efficiency and effectiveness of your manufacturing processes can be significantly increased with the help of individually built process plants. Customized process plants are used by our customers worldwide. Container systems, which can be used flexibly at different locations, are available as well as our skidded units, which are completely frame-mounted and automated production units. Recipe control, visualization, weighing, measurement and control technology, containers and piping, CIP systems - all plants are completely assembled in our factory. After a test run under production conditions they are accepted by you. Our technicians are available to you on site for installation, commissioning and service.

Request for a quote

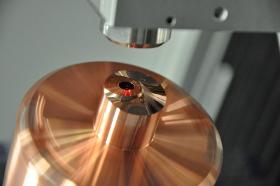

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

Special purpose machines are our specialty. We are able to adapt our standard machines to your needs within a short time or to develop and build completely new machines for your application. Our extensive know-how allows us to accompany you from process development through the design and detailed construction of a suitable machine to measurement, commissioning and the start of production in your plant. In addition, even maintenance or product adjustments if necessary.

Request for a quote

B + B THERMO-TECHNIK GMBH

Germany

The punctual measuring infrared thermometers are especially suited for precise controlling of industrial production processes, in the research and development and for controlling the function of various devices and plants.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

IN STEEL AND STAINLESS STEEL FROM 50 – 10,000 M3 LIPP welded storage tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP and can be constructed with steplessly adjustable volumes of 50 to 10,000 m³ according to the application. LIPP offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to high alloy stainless steels. The automated process meets the highest quality standards. LIPP storage tanks can be produced within a very short time, either on site in the open air or inside a building. The special circumferential profile ensures additional stability compared to conventional processes. KEY BENEFITS Three different welding processes based on the LIPP system and adjusted to the application

Request for a quote

KULLEN-KOTI GMBH

Germany

Kullen Koti End, Cup and Bevel brushes give a gleaming finish to oxidised or coated metal surfaces. They are all-rounders in drilling machines, on angle grinders and in machining centres, performing such tasks as removing paint, scale and corrosion. They are also ideal for use in places which are difficult to get at, and were specially developed for the processing of edges and corners.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Welded Tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP® and can be constructed individually in diameter in volumes of 50 to 10,000 m³ according to the application. LIPP® offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to highalloy stainless steels. The automated process meets the highest quality standards. LIPP® Welded Storage Tanks can be produced within a short time, either on site in the open air or inside a building.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

We know the challenges that new technologies in e-mobility (BEV) entail for established players in the transition from combustion engines to New Energy Vehicles as well as for start-ups in the process of structural development in daily practice. We would be happy to take over for you: quality assurance rework conversions field actions component qualification startup protection Congestion management production management and many other tasks that can be completed quickly and flexibly

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

HT-Tools Pro is a powerful simulation tool for designing and optimizing recipes for carburizing including low-pressure carburizing, carbonitriding, as well as nitriding and nitrocarburizing processes. It can significantly reduce the lead time for process development, replacing time-consuming evaluations and trials.

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

BS-pilotDRY® Series ML001 - ML010 The pilotdryer BS-pilotDRY from BOLZ is well suited for a wide range of various pilot-scaled trials and tests within the product and process development, but also for ongoing quality monitoring of a production. Mainly used as a traditional conical screw dryer, in addition it can also be used as a central shaft dryer. The hybrid stirrer technology allows drying and mixing processes to be simulated and tested in only one appliance using different mixing tools. Therefore relevant comparisons are possible which facilitate the selection of the most suitable stirring mechanism or agitator tool for the product and thus for the future production equipment. Special properties for the customer’s benefit: Mobile and portable skid design Simple „plug and use“ installation Complete process unit with ancillaries Flexible filling volume 10 to 100% CIP-cleaning included All product contact surfaces heatable Suited for a wide range of processes Ideal for...

Request for a quote

SERVOLIFT GMBH

Germany

SERVOLIFT laboratory blenders are ideal for producing small batches under production conditions. This is possible through the container’s geometry, which is adapted from the large production blender. The knowledge gained from blending tests creates a reliable basis for later manufacturing. Parameters such as RPM and time can therefore be varied. Small size - large effect Technical description Compact blender, ideal for product and process development Operate on a control or touch panel Design and geometric relationships correspond to the large production blenders Also available as test and loan unit

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

Uncontrolled electrostatic discharges when handling highly flammable or explosive media often cause personal injuries and damage to equipment. With smaller containers such as drums, buckets and canisters, the risk of electrostatic sparks is often underestimated. For these simple, but no less dangerous processes, Eltex has developed the TERRALIGHT battery-operated ground monitoring system. The TERRALIGHT grounding system shows the user that a correct dissipative ground connection is present and thus ensures a high level of safety when handling highly flammable media. Mobile ground monitoring, e.g. on mobile suction/pumping stations or containers, is also possible. For a safe ground contact, the contactor/clamp is important as an interface between the grounding device and the object to be grounded. For the TERRALIGHT we offer the TERRACLAMP with built-in grounding indicator. The user can see directly on the clamp if the grounding has been done correctly

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Vacuum degassing / outgassing With the aid of vacuum outgassing, unpleasant tastes or odors can be degassed and thus rendered tasteless. Altitude simulation For aircraft transport, it is essential to perform tests and simulations at a pressure <800 mbar, since in cargo holds, pressure equalization takes place, but cannot compensate for all fluctuations. Vacuum storage systems The safest way to store highly sensitive components is under vacuum. Under the vacuum environment, your components are protected from all external influences. Control and process control Our specially developed control program offers not only the possibility to monitor, but also to program and store various process sequences. High and ultra-high vacuum From the pressure range of rough vacuum to fine vacuum and ultra-high vacuum, we are able to meet your process requirements with our systems.

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 092 Cutting, stamping and bending device for radial components Description The Streckfuss model C 092 has been developed to process taped components with holepitches of 12.7 mm and 15 mm with one machine. To eliminate any kind of inconsistencies due to variances in taping, this machine is fitted with a probing- unit that will verify the cut length. The machine was developed with two processing units for multiple die sets. The die inserts can be exchanged very quickly. Because of the dual processing- units a wide range of bending and stamping forms can be processed. Components

Request for a quote

MBW GRUPPE

Germany

"The zinc-nickel process has developed in recent years into a process providing one of the most efficient coatings in surface refinement, and is primarily used where high corrosion resistance at a high temperature load is required. Zinc-nickel alloys with 12-16% nickel content are very temperature-resistant, the higher level of hardness compared to the normal zinc coatings is also a very important property, since the risk of damage is lower. The process is related to the conventional alkaline zinc method, but has excellent durability even without post-treatment. This process is suitable for both barrel and rack goods."

Request for a quote

MBW GRUPPE

Germany

"The zinc-nickel process has developed in recent years into a process providing one of the most efficient coatings in surface refinement, and is primarily used where high corrosion resistance at a high temperature load is required. Zinc-nickel alloys with 12-16% nickel content are very temperature-resistant, the higher level of hardness compared to the normal zinc coatings is also a very important property, since the risk of damage is lower. The process is related to the conventional alkaline zinc method, but has excellent durability even without post-treatment. This process is suitable for both barrel and rack goods."

Request for a quote

MÜLLER GMBH

Germany

Container handling & container lifting Robust and reliable stationary container handling systems are required where high weights have to be managed effectively. In pharmaceutical production, in particular, Müller's well-thought out container lifters are an integral part for the greatest variety of process tasks. We develop mobile and stationary designs to meet your requirements. The stationary container handling systems are equipped with robust forks and a weighing unit, if required. Container lifter with grinder lift column Type FTHSK 1000 G5-2 lifting weight 1000 kg height 6 m Design: lifting, inverting, swivelling, grinding - all motorized Container Wash Station high pressure, 150 bar warm-cold water rotating injection nozzle validation possible Container lifter for rectangular containers lift and swivel column Type FTHS 1000 G4 loads up to 1000 kg column height 5.0 m Design: motorized lift manual swivel Emptying and charge weighing Emptying and charge weighing system for..

Request for a quote

KÖSTLIN PREPRESS SERVICES GMBH & CO. KG

Germany

"Do you need packaging samples for photo shoots, presentations or trade fairs before the actual product launch takes place? We create realistic 3D illustrations of your packaging projects. Early in the design development process, the software solutions already visualize the appearance of your packaging directly from the original print data. In addition, if you actually want to see and feel your packaging beforehand, we create realistic, true-to-detail and color-proofed mockups. Do you need packaging samples for photo shoots, presentations or trade fairs before the actual product launch takes place? We create realistic 3D illustrations of your packaging projects. Early in the design development process, the software solutions already visualize the appearance of your packaging directly from the original print data. In addition, if you actually want to see and feel your packaging beforehand, we create realistic, true-to-detail and color-proofed mockups."

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Process development - Import exportNumber of results

17 ProductsCompany type