- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stainless steel welding

Results for

Stainless steel welding - Import export

IMM MASCHINENBAU GMBH

Germany

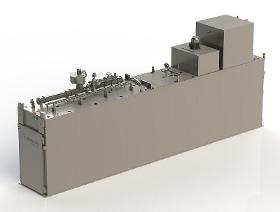

CNC controlled machine for belt grinding and polishing stainless steel weld seams. Belt grinding on the contact wheel or slack belt unit is possible for edge profiling.

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The Autovent 3000 ensures optimal cooking processes at smallest weight loss without any fans at all! Instead, the system's patented nozzles use the internal dynamics of lowpressure steam, converting it into air speed and heating energy. For you, this means Shorter cooking times and weight loss reduced by up to 15%! High turbulences due to patented AUTOVENT nozzles and air velocities of up to 200 m/s Short cooking times and up to 15% less weight loss Temperature difference across the system no more than 1 °C Uniform products at highest quality Very low maintenance and operation costs from dispensing with fans Long service lives from stainless steel construction and steamtight welding allround

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

TECHNOLOGICAL INNOVATION OPENING UP NEW MARKETS The new automated Lipp welding process will again shake up tank construction market just as the well established Lipp double fold system did decades ago. It is a perfect combination of the long experience in metal forming and state of the art welding technology. KEY BENEFITS OF THE LIPP WELDING TECHNOLOGY Automated welding proces, on site Visual weld monitoring and technical documentation Reinforcement ribs for enhanced structural stability and reduced material costs High quality and repeatability Fast installation Choice of different material grades and types CERTIFICATES SPECIFICATIONS OF THE LIPP WELDING TECHNOLOGY BLACK STEEL SPECIFICATIONS OF THE LIPP WELDING TECHNOLOGY STAINLESS STEEL Beside black steel, various grades of stainless steel and duplex steel can be auto welded. In addition to the new potential markets and applications, the Lipp automated welding technology will increase the competitiveness

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The TFi3000 Autovent is a true efficiencywonder! The patented procedure for lowpressure steam cooking without any fans at all, in combination with automated work processes, reduces the operating costs to a minimum. Cooling of the products in the closed system, directly subsequent to heat treatment, also ensures ideal hygiene conditions and increases durability. Production justintime, controllable process with reproducible work processes Automatic transport system Much lower germ formation and contamination – for longer durability Short cooking times and weight loss reduced by up to 15% Temperature difference across the system no more than 1 °C Uniform products at maximum quality due to turbulences and air velocities up to 200 m/s Very low maintenance and operation costs thanks to dispensing with fans Long service lives due to stainless steel construction and steamtight welding allround

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The force to be measured must be introduced axially and perpendicularly to the entire surface of the inner and outer bands of the sensor in the opposite direction. Conversion of the acting force into an electrical output signal is performed by strain gages connected together in a full bridge circuit. To achieve optimal accuracy, the base of the sensor should rest on a smooth level surface, hardened to at least ≥ 58 HRC with sufficient dimensions. The base cover welded to the surface has a stabilizing effect on the sensor element. Lateral forces must be avoided anyway as they distort the measured results. Tension and bending relief for the sensor cable is to be carried out on the machine side. FEATURES: — Measuring ranges from 0 ... 100 N to 0 ... 200 kN — Centric throughout hole — Flat disc design — Made of stainless steel — Completely welded sensor body — Nominal characteristic value standardization possible — burster TEDS optionally available

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ACHBERG SILOANLAGEN GMBH & CO. KG

Germany

pipes (aluminium) - ends cleanly deburred - supplied in trade length of 6 m Ø (mm) FR.038.015.AL 38 x 1.5 FR.040.015.AL 40 x 1.5 FR.045.015.AL 45 x 1.5 FR.050.015.AL 50 x 1.5 FR.050.020.AL 50 x 2.0 FR.054.020.AL 54 x 2.0 FR.060.015.AL 60 x 1.5 FR.060.020.AL 60 x 2.0 FR.065.020.AL 65 x 2.0 FR.070.020.AL 70 x 2.0 FR.076.025.AL 76 x 2.5 FR.080.020.AL 80 x 2.0 FR.090.020.AL 90 x 2.0 FR.100.020.AL 100 x 2.0 FR.108.030.AL 108 x 3.0 FR.114.030.AL 114 x 3.0 pipes (stainless steel) - longitudinal seam-welded pipes - smoothed inner seam - ends cleanly deburred - supplied in trade length of 6 m Ø (mm) FR.038.015.CR 38 x 1.5 FR.040.015.CR 40 x 1.5 FR.045.015.CR 44.5 x 1.5 FR.050.015.CR 50 x 1.5 FR.054.020.CR 54 x 2.0 FR.060.015.CR 60.3 x 1.5 FR.060.020.CR 60 x 2.0 FR.063.015.CR 63.5 x 1.5 FR.065.015.CR 65 x 1.5 FR.070.020.CR 70 x 2.0 FR.076.020.CR 76.1 x 2.0 FR.080.015.CR 80 x 1.5 FR.080.020.CR 80 x 2.0 FR.084.020.CR 84 x 2.0 FR.085.020.CR 85 x 2.0 FR.089.020.CR 88.9 x 2.0 FR.100.015.CR...

Request for a quoteResults for

Stainless steel welding - Import exportNumber of results

7 ProductsCompany type