- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plant installation

Results for

Plant installation - Import export

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR THE STORAGE OF CEREAL PASTE AND SUGAR BEET Lipp plans and sells storage systems for biomass such as cereal paste or sugar beet under the brand names LIGAVATOR and BETAVATOR. These systems are generally gas tight and both roof and container base (optional) are made of solid stainless steel, since the stored media can give rise to very aggressive juices and gases. With this type of storage the substances are preserved and can be used over a very long period. Automatic withdrawal and substrate delivery can also be installed in the following systems by an appropriate control system. APPLICATION EXAMPLES AND REFERENCES In addition to pure crop storage, the Lipp LIGAVATOR / BETAVATOR systems are mainly used as substrate storage for agricultural or industrial biogas plants, and are installed before the fermenter for appropriate substrate supply. They allow largely automated control of a biogas plant, as there is no need for a regular manual substrate supply.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 HME series is a design with bearingless cantilever construction that is directly coupled to the IEC Motor. Specially designed for plant engineering and confined installation conditions. It can be operated in dry installation next to the tank, thus facilitating access for maintenance and repair work. The pump is suitable for pumping /circulating neutral, corrosive and mechanically contaminated liquids. However, it can also be used in stationary installation in the chemical industry and process engineering, in surface and electroplating technology and in gas scrubbers. * temporarily also possible in dry running * directly coupled in bearingless cantilever design * available in immersion depths from 275 - 450 mm Features & Advantages * Service friendly dry running installation * Extremely low vibration and wear operation * Self-centering alignment in the bearing shell * All wetted parts made of corrosion resistant plastic

Request for a quote

BETONBAU GMBH UND CO. KG

Germany

The stable structure of Betonbau modular units enables factory equipping with plant and equipment. Factory installation is particularly economical, considerably reducing your co-ordination outlay for many minor tasks on the construction site. On-site commissioning time is considerably reduced as a result. The spectrum in this respect ranges from the basic 230V/400V installation for lighting, heating and socket circuits to the integration of emergency lighting and explosion protection. We can supply a standardised sub-distribution system with the delivery if requested, meaning you simply have to connect everything on site. Cable trays, electrical heating equipment, ventilators, air conditioning systems and sanitary equipment can be fitted in the manufacturer's facilities if required. Experienced engineers and master craftsmen plan and monitor the production and, together with our installation technicians, ensure that quality and safety standards are reliably realised.

Request for a quote

BETONBAU GMBH UND CO. KG

Germany

Scheduling The co-ordination and integration of the delivery in your project planning is of decisive importance. Many years of experience in the area of heavy cargo logistics ensure precise and safe realisation from the production plant to installation of your building. Cases where large plant components supplied by the customer must be integrated during station installation are also typical. We have therefore staffed this extremely important interface to our customers and business partners with experienced and farsighted scheduling personnel. This also represents the core of our overall logistic and transportation processes. We arrange with the latest supporting systems mobile cranes, all transports and installation personnel to ensure they are in the right location at the right time, taking advantage of optimised delivery programs and well-balanced utilisation capacities to ensure that realisation is particularly efficient. Dedication to deadlines is our highest priority....

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Construction of customized pilot plants Osmo Membrane Systems GmbH is very experienced in layout, manufacturing and start-up of pilot plants. From a container-installed plant which can be designed frost-proof, up to commercial Pilot plants with remote control and online integration, our product range covers a multitude of applications. Depending on the task, we rent an existing pilot plants or we design a new one. Our product range covers laboratory plants like our plant “MemCell” up to large scale plants. The plants can be delivered with an individual visualization. So, this includes data logging and remote control. By request, the plants may be delivered with a customized visualisation system. You are able with the process control system (PCS) to control the plant and a measurement data logging / interpretation system is implemented too. On customers request a secured remote maintenance and remote control will be also installed.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XBK-KABEL XAVER BECHTOLD GMBH

Germany

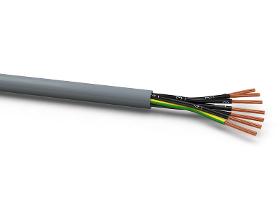

GLOBALFLEX®-H05VV-F conrol cables have been successfully used or many decades as measuring and control cables in tool machinery, plant installation, power stations and in data equipment. GLOBALFLEX®-H05VV5-F control cables are used for forced movements in dry, moist and wet rooms (also water-oil-mixtures) but not suitable for outdoor. Extremely flexible, the GLOBALFLEX®-H05VV5-F control cables are particulary suitable for laying where there is free movement. The product correspondents to the directive 2014/35/EU (low voltage directive). EN 50525-2-51 / VDE 0285-525-2-51 approved CCC approved EAC (GOST) approved

Request for a quoteResults for

Plant installation - Import exportNumber of results

7 ProductsCompany type