- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mixing systems

Results for

Mixing systems - Import export

FESSMANN GMBH UND CO KG

Germany

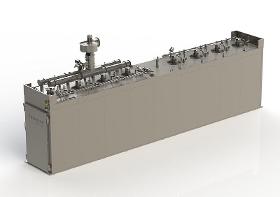

The TF3000 combines the Turbomat T3000 and the intensive cooling system IK3000 in a single closed system. This means one thing most of all Best output per chamber part for the shortest process times. The automated transport system not only reduces operating costs, but also increases production capacities in the system. Maximum output per chamber part Production justintime, controllable and reproducible processes Much lower germ formation and contamination – for longer durability Automatic transport system Producing, packaging and delivery in a very short time Lesser demand of cold storage capacities Higher trolley capacity as comparable floor conveyor systems by low construction

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The SmartMeth™ control system is a fully automated nitrogen methanol mixing system for heat treating furnace atmosphere production. The SmartMeth™ utilizes the latest in precision differential pressure flow measurement and touch screen controller design. This first of its kind system with built-in flow rate calculation automatically sets the nitrogen and methanol flow rates based on a desired %CO furnace concentration. FEATURES & BENEFITS • Automatic flow set point calculation - calculates the required nitrogen and methanol flow rates to maintain a desired %CO at the required volume • Customizable recipe software • Optional integrated carbon and temperature control • Automatic atmosphere recovery provides additional synthetic gas flow on demand, when introducing a new load into the furnace • Integrated paperless chart recorder stores furnace temperature, %carbon, and synthetic gas flow furnace details • Completely assembled and tested to NFPA 86 safety guidelines

Request for a quote

FESSMANN GMBH UND CO KG

Germany

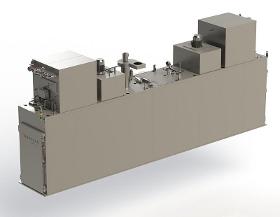

The semicontinuous TFi3000 for industrial use is not a compromise, but rather the combination of the benefits of two entirely different systems! It permits smoke, heat and cold treatments in a single production step. Automated work processes lower your operating costs while at the same time increasing production capacities. Efficient combination of Ti3000 & IKi3000 Production justintime, controllable and reproducible work processes Much lower germ formation and contamination – for longer durability Automatic transport system Producing, packaging and delivery in a very short time Lesser demand of cold storage capacities Higher trolley capacity as comparable floor conveyor systems by low construction

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

The one-part NDT X-ray chemistry ensures absolutely brilliant results in industrial film processing and is tried and tested in oil & gas, aviation, nuclear and military applications. As it is free of hazardous substances, it is not subject to any transport restrictions, it is odorless and free of hazardous and carcinogenic ingredients. It can be used universally and is therefore also suitable for mixed systems with different devices and X-ray films.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The RCV Plus™ Gas Mixing System is a combination of flow meters specifically designed to monitor and control the ratio of two gases. It consists of an RCV Plus™ and a FLO-TRONIC Plus™. The RCV Plus™ utilizes a micro-processor that continuously compares a preset ratio to the real-time ratio of the two gas flows, as measured by the FLO-TRONIC Plus™, and the ratio control valve itself. Using a stepper motor, the RCV Plus™ continuously adjusts the flow metering needle-valve to precisely maintain the preset gas ratio. The real-time ratio is continuously displayed on the LCD screen of the RCV Plus™. Included in the RCV Plus™ is an optional input for the addition of a trim gas, which is frequently used for process control. Trim gas addition is additive to the ratio. When trim gas is used, the continuously displayed real-time ratio then includes the trim gas addition.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNITED PROCESS CONTROLS GMBH

Germany

The EndoInjector™ is a precise gas mixing / control system for endothermic gas generators. It incorporates a patented fuel injection design that utilizes electronic flow measurement and precise ratio control to consistently provide the ideal gas mixture for high quality endo gas generation. The fuel injection design automatically delivers gas mixture on demand, providing only as much endothermic gas as furnaces require to reduce operating costs and eliminate gas waste. EndoInjector™ typically pays for itself in less than 1 year. The ExoInjector™ is designed specifically for exothermic gas generators. While similar in concept, the ExoInjector™ differs from the EndoInjector™ in that it comes in modified mechanical versions to accommodate pre-mix or nozzle-mix burners with a custom HMI software that allows for predefined ratio set points for burner ignition, rich exo, and lean exothermic gas. The system can be modified to provide hydrogen content control and water vapor monitoring.

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

The latest generation of multifunctional YSTRAL PiloTec process equipment offers you the opportunity to use established production processes on a laboratory scale. Thanks to Conti-TDS technology, powder can be inducted, wetted and dispersed under vacuum, dust-free and in a single operation. Easy-to-use swappable tools enable operation using the innovative Multi-Z or Z-Inline process with high-precision multi-stage shear ring systems. Established procedures and a specific energy input independent of the batch size guarantee excellent and consistent results. These can be easily transferred to production scale - a safe scale-up to ystral plant construction. The modular design enables extension to the PiloTec-Plant process plant with ystral mixing technology, systems for handling powders and liquids, measuring technology and sensors, lifting stands as well as other modular components.

Request for a quote

MÜLLER GMBH

Germany

Müller drum and container blenders - almost like plug and play. Blender or blending column, drum or container – bulk solids such as granules or powders are mixed reliably by an intelligent system; which if required can provide a data report for tracking blender settings such as weight, mixing times and number of revolutions. You therefore have complete documentation for your quality assurance system. Müller drum and container blenders are adaptable for your processes: Gentle action Highly effective Safe Blending parameters can be set With data report Blending column with weighing facility Container tumbler FTHMW 1500 MG8 Lifting weight 1500 kg Height 6 m Design: tumbling and weighing - fully automatic emptying Container Blender Lift / swivel / tumble column Type FTHMS 600 MG7 Loads up to 600 kg Column height 4.0 m Design: motorized lift, swivel, grip and tumble actions Stationary blender for drums Tumbling stand Type FTMh 300 MG1 Loads up to 350 kg Height of unit 1.6...

Request for a quote

EKATO RÜHR- UND MISCHTECHNIK GMBH

Germany

"In recent years, the requirements for mixing systems in industrial applications have increased steadily. The design of the impellers, the selection of a suitable mixing system, as well as the arrangement of the individual components on the agitator have a decisive influence on the process engineering and mechanical properties. This not only applies to the agitators but also the reactors and their components. The comprehensive optimization of conventional impellers with industry-specific aspects was the basis for the development of the EKATO impeller family which is continually setting new standards in the field of mixing technology."

Request for a quoteResults for

Mixing systems - Import exportNumber of results

10 ProductsCompany type