- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- forcing

Results for

Forcing - Import export

ETH MESSTECHNIK GMBH

Germany

Customized Solution The quality of the crimped connection is checked by applying a torsional force. In the automotive area for testing the press connection of components for truck and car engines: e.g. fuel injector.

Request for a quote

SITEMA GMBH & CO KG

Germany

In particular applications, it can be necessary to hold high axial forces and torque at the same time. For pneumatic operation, our Locking Unit series KFPD meets this demand. Depending in the size, forces / torques of 12 kN / 120 Nm or 30 kN / 500 Nm can be held securely. The “normal” SITEMA Locking Units KFH are already able to hold smaller torque. Example: 280 Nm with, at the same time, an axial holding force of 100 kN on rod diameter 56. In case higher torque needs to be held, SITEMA’s special design series KFHD can help. With this design, it is possible to hold torque with a factor of 10 higher compared to the standard KFH unit. Example: 2800 Nm with, at the same time, an axial holding force of 100 kN on rod diameter 56. Whether the operation is pneumatic or hydraulic, the application is limited to static holding. The KFPD and KFHD can prevent a rotation from starting, but are not suitable to brake rotating masses.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The SENSORMASTER 9163 covers a wide range of applications in which process values need to be measured, displayed, analyzed and transferred to higher-level control systems. Typical applications include measuring geometric values in production, for instance differential measurements, or testing material properties in the laboratory. The measured values can be transferred via USB, RS232 or analog output. Features: — For force, pressure or torque measurements using strain gauge sensors — For position or angle measurement using potentiometric or DC/DC sensors — For temperature measurement using Pt 100 sensors or thermocouples — Optional multi-channel model — Optional Profibus or serial interface — 0.1 % measurement accuracy plus sensor-specific linearization — Range of mathematical functions (e.g. differential measurement) — OK/NOK feedback on multi color display and via 4 alarm limit outputs — High sampling rate (500/sec.)

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The range of functions has been limited deliberately to ensure operation is simple and self-explanatory. With its unique, large and clear digit height of 20 mm, the digital display can be installed easily in process control panels and control cabinets. Thanks to the large choice of measurement signals that can be indicated, the display is ideal for use in a huge range of industry-based applications. As a simple and compact digital display, it can also be used as a multi-channel solution in laboratory or test systems, where several different measurements may need to be taken and displayed simultaneously. Specific characteristics: — Less expensive digital display — For force, pressure or torque measurements using gauge sensors — Two limit alarms optionally available — Extremely easy-to-read display with 20 mm digit height — Display range -1999 to + 9999 — TARE function — Scaling possible using teach-in procedure or by entering sensor data directly

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The force to be measured must be introduced axially and perpendicularly to the entire surface of the inner and outer bands of the sensor in the opposite direction. Conversion of the acting force into an electrical output signal is performed by strain gages connected together in a full bridge circuit. To achieve optimal accuracy, the base of the sensor should rest on a smooth level surface, hardened to at least ≥ 58 HRC with sufficient dimensions. The base cover welded to the surface has a stabilizing effect on the sensor element. Lateral forces must be avoided anyway as they distort the measured results. Tension and bending relief for the sensor cable is to be carried out on the machine side. FEATURES: — Measuring ranges from 0 ... 100 N to 0 ... 200 kN — Centric throughout hole — Flat disc design — Made of stainless steel — Completely welded sensor body — Nominal characteristic value standardization possible — burster TEDS optionally available

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The newly developed sensor PROFIBUS module model 9221 is predestined for the integration of various analog sensor output signals into complex, net worked and peripheral automation structures. This module finds its fields of application in the industrial automation technology as well as the test rig technology based on its secure and reliable transfer mode, the fast transfer speed and its simple construction. The inputs (e.g. PLC signal gauge) and outputs in addition to the external control allow a zero compensation by trigger via proximity switch or fast alerting on passing of set point values. Industrial type connection and mounting techniques enable the user the adaption and integration in the existing mechanical and electrical environment. The excellent quality of measurement together with the high grade capture of mean values also enable the application in research and development. The use of standardized PROFIBUS protocols makes the connection an easy task for the programmer.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Brake force control valve for stepless regulation of the brake pressure.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Inside the multi-component force transducer are two webs, each offset by 90°, each with a strain gage full bridge, which convert the radially acting X / Y forces on the guide bush into an electrical signal. Due to the sensor body made from a block with its special structure, the sensor has a very high degree of dimensional accuracy and low crosstalk between the two forces. Due to the special design, the sensor has excellent linearity properties and is designed for a long service life in dynamic applications. The two independent signal connections allow flexible adaptation and further processing. Features: — Measuring ranges: 0 ... 4448 N / 0 ... 2224 N (0 ... 1000 lbs / 0 ... 500 lbs); 0 ... 8896 N / 0 ... 4448 N (0 ... 2000 lbs / 0 ... 1000 lbs) — Further measuring ranges on request — Non-linearity < 0.1 % F.S. — Low cross talk < 0.75 % F.S. — High dimensional accuracy, because sensor is made from one part — Excellent price/performance ratio

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

DIGIFORCE® 9311 is the new standard in efficient quality control. The pioneering force/displacement controller delivers rapid, precise evaluation results for applications that demand both high quality and high productivity. The smart performance features and intelligent hardware make test equipment quicker to set up, easier to use and capable of automatic integration in modern production systems. This unrivalled product specification gives businesses the added security and dependability they need for increasingly complex production processes. The DIGIFORCE® 9311 monitors processes in which precisely defined functional relationships need to be demonstrated between two measured quantities of the process. For instance when recording and monitoring processes such as press-insertion, joining, riveting, stamping or caulking, reliable quality control depends on synchronous and high-speed acquisition of measured values combined with analysis based on versatile evaluation elements.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The force measuring chain is an universal reference measuring chain for the calibration of press-fit force measuring equipment. It finds applications in the quality assurance, commissioning and equipment monitoring fields. A DAkks calibration certificate is included so that the force measuring chain can be traced back. The calibration is traceable through accreditation at the German Accreditation Body. The calibration certificate records the displayed values for mounting positions at 0°, 120° and 240°. During calibration in field, the reference load cell is inserted in line with the flux of the press-fit measuring equipment. The force application is of central significance here for the quality of the measurement. Special force application parts are required, so that the line of action of the force agrees as exactly as possible with the geometrical axis of the load cell that is to be measured (central loading).

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The force measuring chain has been developed for applications where the requirements for precision are not the primary focus, but rather where an economical purchase price and simple functionality are the key criteria. The sensor‘s strain gauge technology allows both static and dynamically changing forces to be measured. The large display means that the force acting on the sensor can be read easily. The four integrated threaded holes allow the sensor to be integrated quickly and easily into existing production and assembly equipment. Typical applications include: —Testing the strength of welded joints —Sports medicine —Monitoring the clamping force of hose connections The body of the sensor is a flat, cylindrical disk, into which a domed force application knob is integrated. It is important that the force is applied axially to the center of the sensor.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

LOAD CELL AND TORQUE SENSOR – X/Y/Z - Model 8565 In robotics and automation engineering, the requirements for precise, tactile handling are constantly increasing. The robust 8565 multi-axis sensor with its low crosstalk enables you to monitor and evaluate your process at any time, regardless of the sensor’s orientation. With just one sensor, you can obtain accurate three-dimensional load information. Its six independent outputs let you selectively evaluate the direction of action of the loads (axial force [Fz] / lateral forces [Fx/Fy] / torque [Mz] / bending moment [Mx/My]). Thanks to its compact design and adaptation via the standardized robot flange in accordance with DIN ISO 9049-1, the sensor can be integrated into many applications quickly and easily. When the slightest deviations are detected in your fast-moving and complex production processes, you can intervene immediately to make adjustments. This helps to prevent faulty parts and reduce manufacturing costs.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Model 9180 supports force, pressure and torque sensors operating on the strain gauge principle, as well as the connection of position and angle sensors in potentiometer or DC/DC configuration. It also allows the measurement of process signals ± 1 V/ 5 V/ 10 V or 0 ...1 mA, 0(4) ... 20 mA. The current measured value is indicated on the 14 mm high LED main display, while a second display located directly below provides a reading of the peak value. The display is particularly suitable for highly accurate measurements due to the high accuracy of 0.1%. It is also possible to monitor up to 4 limit values and provide the results via relay or transistor outputs. Thus the process value display can be used for classification, process and control tasks. The current measured value is frozen on the display by activating an external HOLD signal. The TARE function is useful for balancing out previous loads for example.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

With its flat construction this force sensor is specially designed to be fitted to a pedal. By this, the operator's forces for each respective action, for example brake tests, can be measured directly and the reaction of the vehicle or machine can be designated. This applies to real test drives, as well as in driving simulators. Due to the special construction of the membrane, it is irrelevant whether an upright or hanging pedal is concerned. The sensor is designed in a way that unavoidable lateral forces have as little impact on the measurement result as possible. Using a central internal thread on the control surface, various machine-related adaptor parts can be easily mounted. Because the pedal is convex-shaped on its surface, the pedal force sensor has a very rigid base plate and therefore can easily be applied to various geometrics. The mounting can even take place on a pedal with an elastomer covering.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The measuring element of this load cell consists of a double bending beam with strain gauges, the resistance of which changes with the application of force. Upon applying a voltage to the strain gauge bridge, the change in the strain gauge resistance is converted into output voltage, which is directly proportional to the force. The strain gauges and the entire measuring element are protected from water spray by metal cover including sealing material. The tensile or compressive load to be measured is applied to the sensor element through the M6 threaded hole located on each end face. The load can be applied easily, along the sensor axis. This serves to prevent falsification of the measured values. Overload protection can be realized with little effort using a mechanical stop. FEATURES Measuring ranges from 0 … 20 N to 0 … 880 N Relative non-linearity: ±0.25 % F.S. Many load cycles Protection class IP54 Excellent price-performance ratio burster TEDS optionally available

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information Product information Designed specifically for the machines of the AM-/CR-series of Zoller + Fröhlich the crimp force monitoring CK 01 is an integrated component for the automatic monitor of crimping operations and thus ensures high quality crimping products. The crimp force monitoring CK 01 can be directly integrated into the machines from Zoller + Fröhlich or installed externally as a retrofit kit. Special features Precise high-speed, crimp force analysis For wire cross-sections from 0.14mm2 – 6 mm² (AWG 26 – 10) Integrated SPC (Static Process Control) with online option Absolute power measurement in Newton [N] TFT-graphic-colour-display with touchscreen Storing up to 50 different programs and parameters Quality assurance through documentation of each crimp Recognize the following crimp faults Missing strands Improper wire gauge Missing crimp contact Inadequate stripping Improper crimp depth

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The electropneumatic driven, easily adaptable crimpmodule is specifically designed to process loose turned contacts and to be integrated in fully automatic machines. In the range of 0.08 up to 2.5 mm2 (AWG 28 – 14) wires and contacts can be crimped. Standard is a 4/8-indent crimp corresponding to MIL 22520. Optionally is it possible to adapt the machine for other crimpforms. The adjustment of the crimping-depth is motoric, 50 different programs can be stored. The machine can be converted for other contacts by using specific tool kits. All tools are easily replaceable. Options Crimp force monitor Other crimp forms: 4-indent, B-Crimp

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ETH MESSTECHNIK GMBH

Germany

The SM71 series force sensors were specially developed for measuring clamping forces. The short measuring path of 0.019 - 0.14 mm (depending on the measuring range) and a natural frequency in the kHz range guarantee optimal results even for highly dynamic tasks. Typical applications include the simple determination of screw preloads, where the force sensor is used as a “measuring washer”. The very good reproducibility is less than one percent of the nominal load. The sensor is available in measuring ranges from 20 up to 2000 kN. Hardened washers are already included in the scope of delivery for quick and easy installation. The extremely simple and robust design is made entirely of stainless steel (protection class IP68).

Request for a quote

DATAPHYSICS INSTRUMENTS GMBH

Germany

The tensiometers of the DCAT series are measuring instruments for force-based characterisation of surfaces and interfaces. Because of the compact and modular product design of the DCAT series, a bespoke combination of device and accessories can be found for any use case. The DCAT 25 is the multifunctional all-round model of the series. Measurements can be carried out at defined humidity and at temperatures between -15 °C and 300 °C. In addition it is possible to investigate the viscoelasticity of monolayers in combination with the Langmuir trough module LTMr. As the only tensiometer in the DCAT series, this model can analyse the adhesive force extensively thanks to an additional camera module. Measurements: - surface and interfacial tension - liquid density and solid density - dynamic contact angles - surface energy of solids - critical micelle concentration (CMC) - sedimentation and penetration - analysis of adhesive force - surface pressure - viscoelasticity of monolayers

Request for a quote

SAR GRÖPLER GMBH

Germany

Description: Transverse force spindle. Function: introduction of a transverse force on a shock absorber.

Request for a quote

SAR GRÖPLER GMBH

Germany

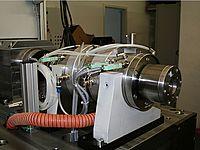

This test rig tests clutch disks.

Request for a quote

ULBRICH GMBH

Germany

The lifting equipment consists of two mobile boogies. Integrated within the superstructure is a hydraulic power pack which drives the two hydraulic cylinders. The cylinders are situated in the highly robust and laterally adjustable lifting blocks. The lifting blocks and the jack contact surfaces (lifting points) can be repositioned along the cross-beam via a spindle. This allows the flexibility to lift and control a number of different types of Locomotive and carriage. Once the carriage has been lifted, the lifting blocks can be locked out using safety bolts which ensure that the height selected is safely maintained. The position of the safety bolts themselves can also be controlled by sensors. An optional function to weigh and calculate the centre of gravity is available upon request. Here, the lifting blocks have been fitted out with “load cells“, which can transfer the load input into a unit of weight. With the accompanying software these values can be evaluated in order to determi

RATEC GMBH

Germany

All series are available with or without handlebar grip and with or without additional holes to accommodate angles. The usage possibilities of the standard magnets can be extended individually through accessories such as longitudinal or frontal suppressing or clamping adapters. — Magnetic rubber (series A) or neodymium magnets (series P and PDA) — Temperature exposure up to 60 °C, series P and PDA on request up to 80 °C — Eccentric removable — Smooth surfaces, easy to clean

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES pneumo-hydraulic marking machines are suitable for applications that need big marking forces. They are available either as complete units with column or C-clamp rack or as built-in units for transfer lines and round cycle facility.

Request for a quote

RATEC GMBH

Germany

The EURO RTM standard magnets were the first magnetic components to introduce magnetic shuttering solutions to modern precast concrete production. With their compact design and reliable retaining force, they are still suitable for many shuttering tasks and are used today in numerous plants. The special shape allows for various accessory components to be slipped over and safely fixed in place through positive locking.

Request for a quote

RATEC GMBH

Germany

With the SPB Standard Pro Magnetic Box, we have set the standard for switchable shuttering magnets in the precast concrete plant. The SPB is the original and offers absolute reliability and durability with its integrated Pro-Magnet, even in difficult conditions. The magnetic retaining core is tested regularly in our own magnet production to meet the specified retaining force. The SPB is ready to accommodate adapters and various shuttering skin carriers, which offer countless usage possibilities and thus maximum flexibility for the future. The Verbus rib screw connection offers countless possibilities for attaching shuttering skin carriers of all types and for integrating systems such as, e.g. Doka, Peri, H-beam carriers or RATEC shuttering systems.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES hand stamping tools are especially used for control stamping, numbering or as a center punch. They are usable as hand held tools or integrated units. These units are easy to use for flexible applications and the stamping inserts are quickly and easy changeable. These features make it to an indispensable tool for craft and industry.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

A regular check of clamping force is vital for a safe, precise, and productive process. Do you manufacture at the highest possible metal removal rates? Perhaps your clamping device can do more than you think! Those who face tough competition can no longer afford to manufacture with »theoretical clamping forces«. Nevertheless the DIN EN 1550 requires that static clamping force measurement must be performed by the manufacturer at regular intervals. Modular measuring system The TESTit clamping force gauge measures and records the clamping force for O.D. clamping and I.D. clamping and even the draw-in force of hollow tapered shank locations. TESTit consists of two parts: The basic unit, which is the IT module, and the measuring units, which are the TEST modules. You only need the IT module once – regardless of whether you want to measure the clamping force at O.D. clamping or I.D. clamping or the draw-in force.

Request for a quoteResults for

Forcing - Import exportNumber of results

29 ProductsCompany type