- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine tables

Results for

Machine tables - Import export

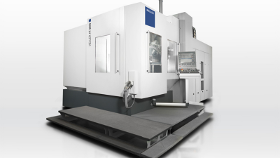

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for powerful complete machining Setting standards in 5-axis: 5-sided and 5-axis simultaneous machining in HELLER quality Highlights Maximum output at optimum quality due to HELLER's extensive process experience Higher availability thanks to adequate speeds and proven HELLER components Innovative spindle technology in three variants providing optimum process stability (swivel head with PCU 63 or SCU 63, fork head with PCT 63) Two control options: Heidenhain iTNC 530 or Siemens Sinumerik 840D sl Advantages Reduced costs thanks to flexible complete machining Optimised life-cycle costs due to innovative manufacturing concept Two machine variants for maximum manufacturing flexibility: workshop machine FT (table loading) for machining of individual parts in tool and die manufacturing and production machine FP (pallet changer) for series production

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

rotating spindle machine for coating rotationally symmetrical parts

Request for a quote

KIRSCH KUNSTSTOFFTECHNIK GMBH

Germany

The vacuum forming process, implemented with simple tools, is ideal for three-dimensional shaping. In modern thermoforming machines with a table size of 1000 x 660 mm up to 2000 x 1200 mm, both negative and positive moulds can be used. Furthermore, we can process the components with our 5-axle-milling-machines afterwards.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine with rotary indexing table and tool magazine. Automatic tool changer with HSK spindle tools. Mosts common tools used are tampico and sisal fibre brushes for bottom, bottom radius and side wall polishing.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

age 2003 banding device for paper and film band table banding machine Ref: BU230308A Please ask for price. We ship and install worldwide!

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

max. size 24 x 20 cm age 2007 banding device max. 25 cycles / min. (off-load) table banding machine electr. foot switch without undercarriage Delivery time: immediately from stock Ref: AF210204A Please ask for price. We ship and install worldwide!

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

On request, we can integrate all of our interferometer systems into our UP machine for quality control in one setting. Be it with a simple strip display or a fully automatic strip evaluation for visualizing the 3D topography. The technical specifications of the intermeter systems are identical to the stand-alone systems.The larger travel range of the MMC900 offers the option of mounting a 6 “interferometer next to the Z axis. After machining the workpiece, the X-table is moved under the interferometer and the surface is measured.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

High-precision absolute angle encoder with flat design with integral bearing Magnetic operating principle therefore extremely insensitive Perfectly suited for applications in CNC machine tools such as rotary tables Serial interfaces for Siemens and Fanuc. Siemens version with Functional Safety certification.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Highly accurate absolute angle measuring system with flat design and integrated bearing. Magnetic operating principle therefore extremely insensitive Perfectly suited for applications in CNC machine tools such as rotary tables. With serial interfaces for Fanuc, Mitsubishi and Yaskawa CNC available.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The C 650 uses a modification of HERMLE's tried-and-tested gantry-type design, with a mineral-cast machine bed. The integrated, rigid clamping table can cope with workpieces up to a maximum of 3000 kg (1050 x 900 x 600 mm) in the 3-axis version, making it ideal for toolmaking, mould construction and machine construction. The swivelling rotary table of the 5-axis version can accommodate workpieces up to 1500 kg (Ø 900 x 600 mm), allowing for highly precise machining. The traverse path in the stainless-steel-clad working area comprises 1050 x 900 x 600 mm with a vertical table clearance of 775 mm and a door aperture of 1050 mm. Ideal parameters for simple and safe crane charging. The C 650 has an integrated tool magazine for 42 tools. The control panel of the C 650 is also designed to swivel easily to the magazine loading location, so the operator can enter the tool data directly into the tool table in the control system.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

MBX magnetic clamping blocks have opposite clamping sides that are activated when actuated. They are designed to clamp workpieces on steel surfaces such as machine or assembly tables. Several MBX can also be connected together via the internal hexagon of the indexing shaft to clamp longer or larger workpieces.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FXL-R round magnetic chucks in square pole technology are especially suitable for use on the lathe and on rotary tables of machining centers. The frame construction of the FXL plate can be equipped with centering elements at the front on the clamping side as well as at the rear. All FXL magnetic chucks can be operated with FXL-C or FXL-CT control units.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Rotary table machines are used for applications that involve production of large counts in cycle time-optimized manner. The machine design allows for dividing the application into several process steps. The number of operating stations depends on the respective task. The individual operating steps are performed in the different stations within the work space simultaneously with loading in the loading area. Indexed tool change is optionally possible.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Shuttle table machines are characterized by an operating area that is separated from the loading station. The plastic parts to be welded can thus be optimally loaded into the equipment. Thanks to good accessibility, assembly and loading tasks can be easily performed. Can optionally be designed with one or more work stations. Approach of several operating positions is performed by means of a freely programmable linear drive. In this way, weld tasks can be divided into individual process steps. Tool change systems: optionally available.

Request for a quote

MOSCA GMBH

Germany

•Corrosion-resistant ultrasonic sealing system with electronic self-calibration •High-end Standard 6 sealing unit •Wear-free DC drives with integrated electronics •Stepless turnable control panel for many-sided operation •Adjustable strap tension via control panel •Switching from maximum to material-friendly Ecospeed in the control •Quick strap coil change •Automatic strap threading system •Strap end detection with ejection of remaining strap •Automatic strap loop ejection •4 castors, 2 of them lockable (Ø 80 mm) •CE marking inclusive conformity declaration •Potential-free contacts to upstream and downstream machines •Continuously adjustable conveyorspeed from 0-1 m/s •Parameter control panel for setting strapping parameters •Selector switch for pass, single, double or multiple strapping •Machine completely corrosion-resistant (main use of V4A stainless steel) •IP 56 protection class design •Sensitive components (e.g. motors) are equipped with additional covers

Request for a quote

OPTIMA LIFE SCIENCE GMBH

Germany

ADVANTAGES Printing: In-line flexographic printing of wallet Compliance: Complies with the industry standards of sterility Flexibility: Processes crepe and hard kraft walleting materials Validation: Fully validated, GMP, CE and OSHA compliant Optional AGPM unit, an online cuffing system that automatically handles glove placement. A link to a platen sealer for outer pouching is possible. PROCESSES Auto-Glove Placement: Automatic or manuel placement of the gloves onto the packaging web Packaging: The wallets are cut off, tucked and folded Transfer of the finished wallets to a packaging table or packaging machine - ideal: HDW Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems.

F. ZIMMERMANN GMBH

Germany

The portal milling machine FZ40 compact is designed for the machining of hard materials as well as aluminum. The inherently rigid machine structure allows for simultaneous 5-axis high speed machining. This compact machine, with its solid cast base does not require a foundation. The machine table is integrated into the cast baseplate, which allows up to 16 metric tons of table load. Eight mounting elements of the FZ40 compact reduce vibration – the basic requirement for high accuracy and optimum surface quality. The sidewalls are filled with a special dampening concrete mix to further enhance performance. The machine has a fully enclosed working space with a fixed machine table. The structural sound overhead gantry with a reinforced Z-ram make up the moving masses. By adding our new dynamic milling head VH60, Zimmermann has created a powerful performer. The combination of high strength and rigidity, constant moving masses and dynamic drives, will meet the industries high demands.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ASSFALG GMBH

Germany

Whether while milling (rough and finish machining), drilling, sawing, welding or assembling, the EPM modules or module systems offer a large selection of clamping options, for example, to clamp during edge milling or deburring (without mechanical clamping equipment) or for the simple and quick fastening of workpieces during assembly. Workpieces can be easily and quickly fastened with the Triplemag magnet clamping elements. The Triplemag series has additional positioning magnets, ensuring a constant position on the machine table and which are separately switched. Through the use of pole extensions, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. Using pole extensions, plane-parallelism of up to 0.01 mm is possible on the workpiece. The processing runs without vibration and an even distribution of holding force is guaranteed throughout the entire ferrous clamping surface.

Request for a quote

ASSFALG GMBH

Germany

The sturdy chamfering machines are designed for chamfering, edge chamfering and welding seam preparation. The machines can process sheet thicknesses from 2-190mm. The machines generate a very good chamfering quality thanks to the optimized interaction between the cutter head, cutting inserts and minimal quantities of lubrication. In NE metals and steel, a chamfer width up to 30mm is possible. The MMB machines have gradual speed regulation, which is very useful when processing aluminum or stainless steel. The angle adjustment can be set gradually in the range of 30° depending on the machine type and design, for example, 25-55°, 30°-60° or 35-65°. The MMB series is equipped with a feed unit by default. The machines can be extended with roller guide ways or converted into automatic chamfering machines. Depending on the design, the machine table is equipped with ball or heavy-duty rollers.

Request for a quoteResults for

Machine tables - Import exportNumber of results

20 ProductsCompany type

Category

- Packing and packaging - machinery and equipment (2)

- Finishing and binding - machinery and equipment (2)

- Precision measuring instruments (2)

- Milling - machine tools (1)

- Machine tools, metal machining - parts and accessories (1)

- Mechanical engineering - custom work (1)

- Measurement - Equipment & Instruments (1)

- Disks, magnetic (1)

- Industrial cutting machine tools (1)

- Magnets (1)

- Metallurgy - machinery and installations (1)

- Polishing - machine tools (1)

- Varnishing equipment (1)