- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heating

Results for

Heating - Import export

FRIGORTEC GMBH

Germany

With the heat pumps from FrigorTec, the energy of a warm aeration / gas removal or waste water is usually exploited. This is often the case in large kitchens, hospitals or the like. But FrigorTec also offers heat pump series, which come into use in building technology and are used effectively to heat residential or commercial buildings.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The high functional safety, especially for heating and stirring technology, ensures a low demand for process energy and this is combined with the benefits of minimal maintenance requirements and a long service life.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

CONTAINER AND SYSTEM SOLUTIONS FOR THE INTERMEDIATE STORAGE OF HEAT FROM WASTE HEAT OR RENEWABLE ENERGIES The intermediate storage of heat from biogas plants, biomass cogeneration plants or other heat sources is an important prerequisite for effective use. Lipp buffer tank systems are economic system solutions for the storage and supply of thermal energy and can be easily integrated into customised solutions for local heat supply. LIPP BUFFER STORAGE TANKS The individually tailored solution appropriate to heat storage requirements with useful volumes of 80 to 3,000 m³ is made of stainless steel with the Lipp dual seam system and operated in conjunction with insulation adjusted to the application at about 95 ° C. Since the Lipp system is unpressurised, the container solutions are extremely low maintenance and are very durable. The high volume, above ground Lipp storage tanks have been specially developed for this application and are popular with end users and energy suppliers alike.

Request for a quote

FESSMANN GMBH UND CO KG

Germany

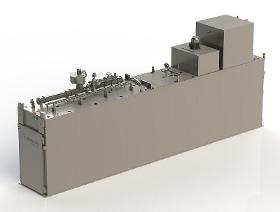

The TFi3000 Autovent is a true efficiencywonder! The patented procedure for lowpressure steam cooking without any fans at all, in combination with automated work processes, reduces the operating costs to a minimum. Cooling of the products in the closed system, directly subsequent to heat treatment, also ensures ideal hygiene conditions and increases durability. Production justintime, controllable process with reproducible work processes Automatic transport system Much lower germ formation and contamination – for longer durability Short cooking times and weight loss reduced by up to 15% Temperature difference across the system no more than 1 °C Uniform products at maximum quality due to turbulences and air velocities up to 200 m/s Very low maintenance and operation costs thanks to dispensing with fans Long service lives due to stainless steel construction and steamtight welding allround

Request for a quote

FESSMANN GMBH UND CO KG

Germany

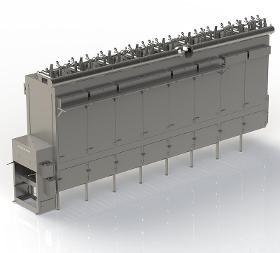

The multifunctional TF4000 by FESSMANN combines highest production capacities with best quality. In the continuous system, the products go through several heat treatment and cooling units, and leave the machine ready for packaging. The innovative serpentine conveyor technology achieves the shortest process times at the lowest weight loss – and decisively reduces the amortisation time of the system!Considerable saving of energy costs Use of any smoke system possible Only 25% of the space demand of batch systems for best return on very small space Fully automatic control and monitoring of the production processes Temperature and humidity can be controlled separately in every treatment zone Unparalleled hygiene, separation of goods input and output (HACCP) Outstanding quality results in colour and flavour at minimal weight loss as compared to batch systems

Request for a quote

FESSMANN GMBH UND CO KG

Germany

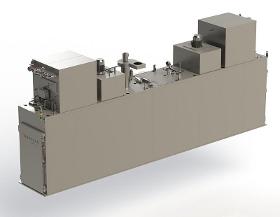

The semicontinuous TFi3000 for industrial use is not a compromise, but rather the combination of the benefits of two entirely different systems! It permits smoke, heat and cold treatments in a single production step. Automated work processes lower your operating costs while at the same time increasing production capacities. Efficient combination of Ti3000 & IKi3000 Production justintime, controllable and reproducible work processes Much lower germ formation and contamination – for longer durability Automatic transport system Producing, packaging and delivery in a very short time Lesser demand of cold storage capacities Higher trolley capacity as comparable floor conveyor systems by low construction

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Heat protection and fire protection for pipes and hoses. Also available as mats or rolls for surfaces

Request for a quote

REINHARDT GMBH

Germany

Since decades, Reinhardt ovens “Made in Germany” are working day by day all over the world and are estimated by their reliability and long life time. Adapted to your requirements, a Reinhardt oven delivers the best results that are completely designed to your production process. In the temperature range up to 650° Celsius Reinhardt offers the best solutions for almost all requirements, for heating, tempering, drying, hardening, etc. all designed to your space conditions. All heating technologies, from electrical, direct or indirect gas, oil can be applied. Together with the customer, the Reinhardt industrial ovens are integrated into the production flow. In a classical batch oven, hood oven or pass through oven all thermal processes can be applied with the highest accuracy. Requirements such as lifting doors, charging carrier, transport and handling systems can be easily applied.

Request for a quote

HIMMELWERK HOCH- UND MITTELFREQUENZANLAGEN GMBH

Germany

Our high frequency converters are providing frequencies of up to 2 MHz at up to 200 kW output. For lower frequencies down to 4 kHz we have our mid range frequency converter series MU.

Request for a quote

HIMMELWERK HOCH- UND MITTELFREQUENZANLAGEN GMBH

Germany

Our mid range frequency converters are delivering up to 250 kW output at frequencies down to 4 kHz. For high frequencies up to 2 MHz we have our high frequency converter series HU.

Request for a quote

HIMMELWERK HOCH- UND MITTELFREQUENZANLAGEN GMBH

Germany

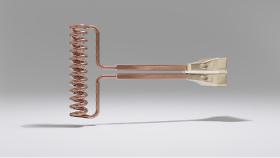

Our Inductors are individually crafted for your exact production process. This ensures point perfect delivery and is maximing the energy efficiency of your heating process.

Request for a quote

FRIGORTEC GMBH

Germany

Using the DEBUGGER method (heat treatment) from FrigorTec, the DEBUGGER DB18 has proven its effectiveness in killing insects, larva, and eggs, for decades. This method increases the air temperature to a range between 45°C and 60°C, and keeps it there, so that pests die off without using chemical substances, thus preventing damage to buildings and their fittings. A power distributor is required depending on the size of the installation site or the number of devices, and we recommend using one or more SCRAMBLER SC 6000s to save energy. Fields of application > Specially developed for large spaces, e.g., mills, bakeries, the food-processing industry > Often used in spice and coffee processing, as well as in the tobacco industry, muesli manufacture, and small animal feed production > Combine several DEBUGGER DB18s in very large rooms and halls

Request for a quote

FRIGORTEC GMBH

Germany

With an AGRIFRIGOR™ dehumidifier air is conditioned for drying hay. The process is particularly economical and effective by using a heat pump. This is possible because the evaporator and the condenser are used in this process. Hay in the best quality produce good milk & good meat; the health of the animals is significantly improved.

Request for a quote

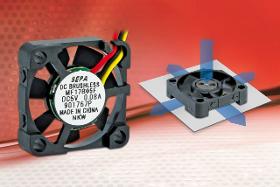

SEPA EUROPE GMBH

Germany

Inspired by customer inquiries, SEPA EUROPE has developed a new, modular assembly for the efficient cooling of chips. The core component is a SEPA axial fan that is mounted on a 40 mm pure aluminium heat sink – a so-called Kühligel®. It is equipped with a finger guard and a double-sided adhesive heat pad for screwless mounting on the housing or inside the device. Thanks to the compact design, the light weight and the screwless mounting, this assembly enables accurate positioning and thus effective cooling of the hot spot. The chip cooler HXB40FGK is equipped with a high precision ball bearing and can be used at ambient temperatures between -10 and +85 °C thus opening up a wide range of application possibilities. A further advantage is the long service life of the fan with 350 000 h (MTBF) at 40°C. The chip cooler assembly HXB40FGK is supplied as a standard component. It can however, be customized.

Request for a quote

SEPA EUROPE GMBH

Germany

The chip cooler of the HXB series by SEPA EUROPE is a compact combination of fan and heat sink and is an attractively priced combination with an adequate cooling capacity. But the development engineers at SEPA EUROPE wanted to go further and this pushing ahead marked the birth of the 3DQler. The cooperation with the experts of APWORKS provided the decisive impulse. Due to the metal 3D printing, also known as additive manufacturing, APWORKS is in the position to produce geometrically highly complex heat sinks. Without having to change the external dimensions or make the fan more powerful, the additively manufactured version can be realized with 30% more efficient waste heat. With the 3DQler, SEPA EUROPE and APWORKS have developed a modern and active cooling concept that offers numerous advantages: Freedom of design with regard to installation space and a reduction of the manufacturing costs.

Request for a quote

SEPA EUROPE GMBH

Germany

Chip cooling with the aid of heat sinks usually requires a lot of space and is not only heavy but also expensive. The specialists at SEPA EUROPE have developed a chip cooler with minimum space requirements for compact designs. The core component of the compact cooler is the ultra-flat blower HY40H that is combined with a Kühligel® of pure aluminium. The special feature of the new cooling solution is its variability which means that the size and shape of the heat sink can be freely chosen. Users can thus assemble the cooler to optimally fulfil their requirements. With a thermal resistance of a mere 2.5 K/W, the new chip cooler withstands a power dissipation of up to 15 W and in doing so guarantees the operational safety of the entire embedded system. The blower is equipped with the highly durable Magfix® sleeve bearing and has an impressive service life expectancy of von 210 000 h (MTBF) at 40 °C.

Request for a quote

SEPA EUROPE GMBH

Germany

One of the most popular SEPA EUROPE fans is the axial fan with the dimensions 40x40x10 mm and the popular Magfix® sleeve bearing. This year it underwent complete revision and further development. The new fan generation is known as the LF40P and with the same external dimensions is installed in the same way as the previous model. The new and currently unique rotor geometry is obvious at first sight. It is completely different from the previous shape and layout. Thanks to the distinctive rotor blade with a cut, either a clear noise reduction can be achieved at the same speed or the same noise level as previous generations with 25% more air performance. The current model is equipped with the SEPA MagFix® bearing and PWM input with which the speed can be set to meet the necessary requirements. The LF40P is an excellent example for the permanent further development of products at SEPA EUROPE.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SEPA EUROPE GMBH

Germany

The significance of air quality measurements whether in industry, households or in vehicles is constantly increasing. Manufacturers therefore, should equip their applications with the optimal sensor fan and in this respect SEPA EUROPE is exactly the right partner! SEPA EUROPE has complemented its range of microfans with the radial fan HY20A with the dimensions of 20 x 20 x 6.3 mm. The air intake of the radial fan which is on one side is 2 l/min and with a sound pressure level of 5dB(A) at a distance of 1m, it is virtually inaudible. As is the case with all microfans, the HY20A is equipped with the reliable Magfix sleeve bearing and has a service life of 400 000 h (MTBF) or 50 000 h (L10) at 40°C. The tachometer output constantly monitors the speed at which the fan is running. The HY20A is also an interesting solution for the cooling of hot spots in embedded applications. This compact blower ensures that optimal use is made of limited installation space.

Request for a quote

SEPA EUROPE GMBH

Germany

Even the micro fan MF17B05 from the RaAxial range was a true innovation simply because it can be used not only as an axial fan but also as a radial fan. The micro fan has now a „big brother“– the LF40E05. The LF40E05 provides numerous possibilities for embedded applications. It can be used either as an axial fan with integrated finger guard or as a radial fan in combination with a heat sink. Together with a matching Kühligel® the flat cooling units have a height of approx. 12 mm. In other words, they are ideal for compact applications. In order to achieve the optimum size and heat dissipation, customized dimensions and shapes can be realized. The new model with its 0.15 W power input during operation, is extremely economical with regard to its diverse application possibilities. And that’s not all, the new RaAxial fan has aerodynamically optimized blades that have a significant effect on the noise behaviour. The LF40E05 is thus exceptionally quiet.

Request for a quote

SEPA EUROPE GMBH

Germany

The fan and cooling specialist SEPA EUROPE has now added three further models to its slimline radial fan series. The latest additions impress with their compact dimensions of 38 x 40 x 5 mm, 54 x 52 x 6 mm and 45 x 45 x 4 mm and have more than deserved the name „slimline“. All fans are equipped with the reliable Magfix sleeve bearings and have a service life of 210 000 h (MTBF) and 40 000 h /L10) at 40 °C. The PWM input in combination with the tacho output enables the speed to be controlled and monitored. It is not obvious at first glance, but the Model HY45AB05PNK00A tops with a pressure of 143 Pa. The new models will be included in the standard range and will therefore be available shortly from stock. SEPA EUROPE specializes in customized cooling solutions. Thanks to over 25 years of experience, SEPA EUROPE can offer you the appropriate solution for virtually every task.

Request for a quote

SEPA EUROPE GMBH

Germany

The fan and cooling specialist SEPA EUROPE unveils a true innovation this year: The RaAxial fan. This created term is a combination of the words radial and axial. The microfan with its dimensions of 17x17x4.5mm is ideal for compact, embedded applications and offers numerous possibilities, e.g. as an axial fan for the ventilation of housings or as a radial fan for blowing air onto the heat sink. A tailor-made „Kühligel®“ has already been developed for the latter which makes the cooling of hotspots child’s play when space is limited. Reliability has top priority at SEPA EUROPE. For this very reason the new fan is equipped with the tried and tested Magfix® bearing system. The life expectancy at 40 °C is 210 000 h (MTBF) or 40 000 h (L10).

Request for a quote

SEPA EUROPE GMBH

Germany

SEPA EUROPE offers a 40 mm frameless fan especially for embedded systems. It is 10 mm high and provides a compact solution for chip cooling when used in combination with the appropriate heat sink. In addition to the 50 mm frameless fan which is already on the market, the new round 40 mm fan is also a much sought-after model for embedded systems. This is because many standard cooling solutions in this business sector are based on the 40 x 10 mm fan. Strictly speaking, the 40 mm fan has a rotor diameter of 37 mm. The version offered by SEPA EUROPE is equipped with two ball bearings and can boast a remarkable service life of 70.000 h at a temperature of 40°C. In addition to an impulse output for speed monitoring, it also has a PWM input for speed setting in the range of approx. 35 – 100% of the nominal speed. In conjunction with the power block pin-fin heat sink, this virtually silent fan with 22 dB(A) is also available ready for connection in the „Kühligel“ version.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

Based on years of experience in the field of test bench metrology in the automotive industry, EP develops test bench solutions for various applications. We build test benches for testing automotive components such as heat exchangers, intercoolers, filters, valves and others. These are test benches on which e.g. supplier parts for the automotive industry are tested in production. Our specialist knowledge of the industry makes us a strong partner in this area.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

More than SCADA. The Protherm 9800 is a modular production management software for supervising, controlling and archiving heat treating processes and heat treatment installations. It delivers everything to optimize the performance and efficiency of a heat treatment plant operating a variety of furnaces as well as automatic handling machinery. By combining process control, equipment integration, and automation capabilities, the Protherm 9800 provides a comprehensive approach to plant wide supervisory control and management. FEATURES • Highly detailed visualization of all furnaces and connected devices • Scalable set of functions • Module for fully automated production system/cell (lights-out) • Easily implementable interface to existing planning and production systems • Possibility of simulating heat treatments

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Protherm 10 is a cost-effective temperature and industrial controller with expanded functionality, including a programmer and an optional datalogger.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Protherm 455 is a ½ DIN powerful controller designed to monitor, control and record a variety of heat treating processes. Used in new furnaces as well as for refurbishing or updating existing systems, it is ideal for nitriding, nitrocarburizing, carburizing, carbonitriding, hardening, tempering and vacuum furnaces. FEATURES • color touch-screen interface • built-in chart recorder function • calculates variables such as % carbon, dew point, or millivolts, and percent oxygen • stores up to 200 19-step recipes • direct drop-in replacement for Marathon Monitors’ CarbPro, DualPro, MultiPro, and Carb PC • works with internal and/or external I/O’s • suitable for all types of processes such as nitriding, nitrocarburizing, carburizing, carbonitriding, plasma and vacuum • standard connectivity allows for integration with SCADA systems • for compliance with CQI-9, AMS 2750, & AMS 2759/10-12

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Protherm 470 controller is designed to monitor, control, record and archive heat treatment processes running in a furnace or simultaneously in multiple chambers. They are configurable for various types of batch and continuous furnaces. Installations are done on new or refurbished furnaces and are used for updating existing systems. FEATURES • ½ DIN multi-loop embedded programmer with a color display and turn-and-push knob navigation • Up to 32 programmable PIDs included • built-in calculators for real-time carbon and/or nitrogen diffusion, and hardness profile • mathematical model for calculating atmospheric parameters • integrated web server for browser-based remote access • works with internal and/or external I/O’s • suitable for all types of processes such as nitriding, nitrocarburizing, carburizing, carbonitriding, plasma and vacuum • standard connectivity allows for integration with SCADA systems • for compliance with CQI-9, AMS 2750 & AMS 2759/10-12

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Protherm controllers are universal configurable programmers that monitor, control and record processes running in a single furnace or simultaneously in multiple chambers. They are configurable for various types of batch and continuous furnaces. Installations are done on new or refurbished furnaces and are used for updating existing systems. FEATURES • Up to 32 PID control-loops to regulate parameters such as temperature, furnace pressure, atmosphere parameters (e.g.: carbon potential, nitriding potential and oxygen potential) • Real-time monitoring of jobs at all stages • Process parameters configured with alarm limits • Online diffusion calculation to control the process using required target values (e.g.: case depth, surface carbon content) • Up to 999 treatments/templates can be created and modified • Integration with SCADA systems • For all types of processes: nitriding, nitrocarburizing, carburizing, carbonitriding, plasma and vacuum • For compliance with CQI-9, AMS 2750 &..

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

The name “CUSTOM” already says it all: HF generators of this series are configured precisely for the relevant production task. Their HF power ranges from 100 to 1,500 kW. The frequency range is 80 to 400 kHz. Induction generators with high power density On this basis, numerous combinations of power and frequency are possible – a key prerequisite for effective induction heating. eldec induction generators also provide high-precision energy dosing, which guarantees the reproducibility of the process. In addition, CUSTOM LINE HF generators are available with a comprehensive bundle of options: Offers include hose bundles of various lengths, a Profibus interface, pyrometer-based temperature control, as well as a cable box with a heating cable for shrink applications.

Request for a quoteResults for

Heating - Import exportNumber of results

55 ProductsCompany type

Category

- Induction heating systems (19)

- Ventilators and fans - industrial (9)

- Heat exchangers (5)

- Cooking and smoke-curing equipment for delicatessens (3)

- Heat pumps, industrial (2)

- Heat recovery systems (2)

- Electroheat - machines and equipment (2)

- Electrical & Electronic Components (2)

- Tanks, metal (2)

- Driveshafts and micro-motors - electric (2)

- Electricity - production and distribution (2)

- Heat treatment furnaces (1)

- Agricultural systems and equipment (1)