- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- handling transporter

Results for

Handling transporter - Import export

EUGEN LÄGLER GMBH

Germany

The lightweight and compact drum sanding machine! Ideal for smaller surfaces and popular in the rental business. Especially DIY enthusiasts like to rent the PROFIT, because it is easy to handle and transport. Based on proven LÄGLER® technology, the PROFIT with its centrifugal drum is also a good option for private users. The abrasive sleeve can be changed quickly and easily. Its compact design and the resulting manoeuvrability make it suitable for smaller areas. Despite its relatively low weight, the PROFIT achieves good work quality and an appealing sanding performance. Applications with the PROFIT: The PROFIT is mainly used for sanding of wooden floors. It shows its strengths especially in easier renovation works and the treatment of small and hard-to-access areas.

Request for a quote

REINHARDT GMBH

Germany

Since decades, Reinhardt ovens “Made in Germany” are working day by day all over the world and are estimated by their reliability and long life time. Adapted to your requirements, a Reinhardt oven delivers the best results that are completely designed to your production process. In the temperature range up to 650° Celsius Reinhardt offers the best solutions for almost all requirements, for heating, tempering, drying, hardening, etc. all designed to your space conditions. All heating technologies, from electrical, direct or indirect gas, oil can be applied. Together with the customer, the Reinhardt industrial ovens are integrated into the production flow. In a classical batch oven, hood oven or pass through oven all thermal processes can be applied with the highest accuracy. Requirements such as lifting doors, charging carrier, transport and handling systems can be easily applied.

Request for a quote

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

How do you normally transport large OSB or particle boards? That usually requires multiple employees and work steps in order to transport heavy and bulky goods from A to B. Thanks to AERO-PORO vacuum lifters from AERO-LIFT, such problems are now history! Now your existing crane can be made much more effective by adding an AERO-PORO lifter. The crane operator can now lift, transport, swivel and deposit workpieces all on his own. Safely without damage and assistance. Tailored to your requirements, our AERO-PORO lifters are able to transport very large panels with ease and can even generate a reliable vacuum when handling porous materials. Previous Next Functionality and characteristics Handling, transport and swivelling of hundreds of kilo heavy porous wooden boards in saw mills, carpenters and in the wood and furniture...

Request for a quote

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

In addition to a horizontal transport, the load can be turned: either manually by sheer muscular strength and a prying effect or pneumatically. That way, even large and heavy loads can be moved quickly and easily to the desired position. Due to flexible operating handles, bulky materials can be lifted and lowered easily even at great heights. An extended operating handle is provided for the transport of plate materials and large goods. The tube lifter can be switched on and off via radio by means of a small transmitter located at the tube lifter. To reduce noises, the blower can be mounted inside a sound insulation box. In addition, the blower can be mounted at walls or columns by means of optional mounting brackets. You wish to transport different goods? The optional quick-release coupling can be used to change the suction pads quickly and easily. Optionen und Einzelkomponenten für Schlauchheber Bendable handle, inox suction head with rotary handle suction head with strap...

Request for a quote

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

For each good to be transported and each application, numerous load handling units are available. No matter if the good to be transported is uneven or unstable, whether sacks are not filled properly or cartons are provided with a hooping, the right load handling equipment will make the transport possible. Due to a quick-release coupling, the load handling equipment can be changed quickly to transport different goods. barrels, sucking from above barrels, sucking from side suction cup for cartons suction cup for 4 cartons suction cup for paper and foil coils Food for boards, pneumatic swivelling Handling of chimney elements paletts gripper sacks, tube lifter inox Handling of water canisters carton handling, fixed at side Hook to handle canister and buckets mechanical gripper for boxes

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

Vacuum lifting devices standard are for the horizontal handling of plates. Transportation auf sheet metal, plastic plates, covered wooden plates or glass panes up to 2000 kg. Loading and unloading of machine tools. All AERO-LIFT vacuum lifing devices are build according the actually safety regulations EN13155. Standard lifting device AERO 350-6R Functionality and features Die Vakuumerzeugung der Vakuumheber geschieht durch wartungsarme trockenlaufende Drehschieberpumpen , ölumlaufgeschmierte Vakuumpumpen mit sehr hohem Endvakuum, druckluftbetriebene leistungsstarke Vakuumejektoren beim AERO-LIGHT oder Vakuumgebläse mit Sicherheitsnachlaufschwungmasse bei luftdurchlässigen Transportgütern. Alle AERO-LIFT-Vakuumheber haben eine nach EN13155 vorgeschriebene automatisch...

Request for a quote

KABELMAT WICKELTECHNIK GMBH

Germany

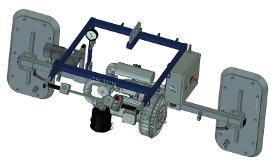

This unwinder is used for all kinds of winding materials. Its special advantages are the double mounted axle as well as the adjustable brake which ensures steady material unrolling. TROMTRAK 1250 is ideal as supplement for cut-to-lenght, dismanteling and stripping machines. Being equipped with lockable steering rollers which allows a flexible handling in transportation and storing area.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The core technology is a robust, water-cooled travelling column. With increasing depth of immersion into the material, the guide carriage distance grows and this leads to advanced rigidity. The stepped drive guide ensures a perfectly constant geometry along the Z axis. This in turn guarantees maximum rigidity in sensitive areas of the workpiece. Used in combination with the highly dynamic Zimmermann milling heads, the FZH400 ensures an extremely efficient milling process during the machining of aluminum and composites. The versatility of the M3ABC 3-axis milling head improves efficiency due to the maximized material removal rate, in particular when machining structural parts. An integral standard component of the FZH400 is its pallet handling capability with an area for setting up pallets during machine operation. The newly developed handling system permits the reliable transportation of the pallets, is suitable for longer pallet lengths, and can be extended without difficulty.

Request for a quoteResults for

Handling transporter - Import exportNumber of results

9 ProductsCompany type