- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic process

Results for

Automatic process - Import export

ECKARDT SYSTEMS GMBH

Germany

High-tech system for maximum process reliability. Automatic nozzle SDA 30: high-tech system for maximum process reliability The SDA 30 is an integrated system consisting of a nozzle and a control module. The nozzle is equipped with a Hall sensor that monitors and controls the position of the nozzle needle. All operational settings/adjustments (oil rate and so forth) are automated via the controller of the proprietary Eckardt control unit. This makes it possible to control up to four nozzles at the same time.

Request for a quote

FESSMANN GMBH UND CO KG

Germany

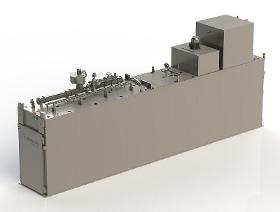

The TFi3000 Autovent is a true efficiencywonder! The patented procedure for lowpressure steam cooking without any fans at all, in combination with automated work processes, reduces the operating costs to a minimum. Cooling of the products in the closed system, directly subsequent to heat treatment, also ensures ideal hygiene conditions and increases durability. Production justintime, controllable process with reproducible work processes Automatic transport system Much lower germ formation and contamination – for longer durability Short cooking times and weight loss reduced by up to 15% Temperature difference across the system no more than 1 °C Uniform products at maximum quality due to turbulences and air velocities up to 200 m/s Very low maintenance and operation costs thanks to dispensing with fans Long service lives due to stainless steel construction and steamtight welding allround

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The Z+F WireDancer is an unrolling aid for wires from cardboard packaging or coils from different manufacturers and is therefore an ideal accessory for any cable production. Unwinding devices are key players in streamlining material handling during cable assembly. Tailored to efficiently dispense cable reels, these devices contribute to heightened precision and productivity. Central output of the wires Unrolling kit „Coils“ enables processing of cable reels in loose form (coils) Integrated magnets ensure easy fixation in the cardboard box Connecting to any processing devices (manual, semi-automatic or fully automatic processing) Easy placement of the Z+F WireDancer in different carton sizes

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The electric cutting machine impresses with its compact build, quick processing times and flexible applications. Special features: Easy operation due to its 5“ display Simple insertion of wires Horizontal working level for improved insight into the operating area Guided conduction of cut wires Possibility to generate complete projects on the machine Optional extension for multiple infeed with the Z+F EVOFEED Full integration into the WPC is possible Multiple infeed Z+F EVOFEED By providing up to 12 conductors it is possible to sequentially process complex projects in a simple and effective way. The automatic feeding process makes manual interference obsolete and allows the processing of different cross-sections or colors according to the respective planning. This is very time-saving for the overall process, as individual jobs and projects can be processed autonomously.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

More than SCADA. The Protherm 9800 is a modular production management software for supervising, controlling and archiving heat treating processes and heat treatment installations. It delivers everything to optimize the performance and efficiency of a heat treatment plant operating a variety of furnaces as well as automatic handling machinery. By combining process control, equipment integration, and automation capabilities, the Protherm 9800 provides a comprehensive approach to plant wide supervisory control and management. FEATURES • Highly detailed visualization of all furnaces and connected devices • Scalable set of functions • Module for fully automated production system/cell (lights-out) • Easily implementable interface to existing planning and production systems • Possibility of simulating heat treatments

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Pharma Design - Series H 630 - 1600 P The HEINKEL horizontal peeler centrifuges in pharma design are characterized by easy cleaning and inspection avoiding product contamination. Special properties for the customer’s benefit: Swinging open housing for easy inspection Clean room installation possible Hydraulically operated housing locking mechanism by single clamping elements, therefore minimal area for product deposit Fully automatic, validated CIP-process possible Design virtually free of dead spaces, minimized number of screwed connections in the process housing Filtrate outlet at the rear part of the process housing, low dismantling expenses to prepare for the opening of the housing High flexibility at frequent product changes Quick change of the filter element Bearing designed as exchangeable unit

Request for a quote

SERVOLIFT GMBH

Germany

The SERVOLIFT cleaning station ensures optimal internal container cleaning in a fully automated process. This is based on a 4x washing program, which provides reproducible wash cycles combined with user- and recipe management. Suitable wash programs are defined which are adapted to individual contamination and container geometry. Wheels and an ergonomic handle make the system movable and easy to manoeuver. The integrated printer documents the individually executed steps of the washing cycle. Outside cleaning is done manually, and completes the entire semi-automatic washing process. The system can be extended to a validation-capable, separate drying station in order to reduce production container downtimes. As an alternative, one can integrate a drying unit into the semi-automatic wash station. Flexible and easy cleaning Technical description PLC control, adhering to GAMP 5 guidelines with password and recipe management up to CFR 21 part 11 implementation Cleaning cover with...

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

Electrostatic Innovations from Eltex have been creating safety in hazardous areas for over 60 years: Controlled electrostatic grounding protects production sites and employees when handling highly flammable and explosive substances. During filling or decanting processes involving potentially explosive liquids or materials, the Eltex Terracompact II automatically identifies faulty, disrupted or defective ground links in the installation. Any disruption in the ground links results in an automatic shutdown of the process. The Terracompact II is a standard enclosure for mounting on DIN 46277 top-hat rails for installation in a control cabinet or a control room.

Request for a quote

PAUL LEIBINGER GMBH & CO. KG

Germany

The WINJET3 XY software controls the travel paths of the JET3up print head with great flexibility. In combination with an XY-traverse system like JETmotion or other XY-traverse systems, product ranges can be printed automatically from left to right and from top to bottom. The software calculates the optimum travel path on a XY-traverse system before printing and then adapts the path automatically to the quickest processing time. The program can be adapted flexibly to new product ranges.

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/B Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height and - if necessary - marked. This axial taped components are processed in high- components. The machine type C 043 / B can be adjusted using the adjustment spindles cutting length and the embossing position. The setting is displayed on the relevant scale of the device. Optionally can be monitored through a digital display setting. The embossing tool is specifically for connecting pins and is manufactured according to customer requirement. The machine can be upgraded for the various tools. The taped components are fed into the machine and processed automatically. The transport speed is infinitely variable. The tool change for other forms of bending takes about 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/E Cutting, stamping and bending device for axial components Description The Streckfuss machine Type C 043/E is designed, to cut stamp and bend axial leaded components for both horizontal and vertical mounting. To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Option: the adjustments can be checked by a digital display. The stamping result for the leads depends on the used tool. These tools can be manufactured to meet customer requirements. The machine can be re- set for the different tools. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 2 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/ES Cutting, stamping and bending device for axial components Description To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Cutting length and pitch are fully adjustable. The stamping result for the leads depends on the used tool. Leadforming ist tool specific and can be manufactured to meet customer requirements. The difference to the types C 043 and C 043 E is the integrated Pneumatic which makes the rearrangement of the Bending- and Formingtools possible. This means, that the tools can be approached to the components. Espacially bendings with Flush- Mount- bead can be done. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/BS Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height and - are marked - if necessary. This axial taped components are processed in high- components. The machine type C 043/BS can be adjusted using the adjustment spindles cutting length and the embossing position. The setting is displayed on the relevant scale of the device. Optionally can be monitored through a digital display setting. The embossing tool is specifically for connecting pins and is manufactured according to customer requirement. The machine can be upgraded for the various tools. The taped components are fed into the machine and processed automatically. The transport speed is infinitely variable. The tool change for other forms of bending takes about 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043 Cutting, stamping and bending device for axial components Description The Streckfuss machine Type C 043 is designed, to cut stamp and bend axial leaded components for both horizontal and vertical mounting. To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Option: the adjustments can be checked by a digital display. The stamping result for the leads depends on the used tool. These tools can be manufactured to meet customer requirements. The machine can be re- set for the different tools. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 2 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 067 Cutting, stamping and bending device for radial components Description The Streckfuss machine Type C 067 is designed to process power transistors of types TO 18, TO 92, TO 126, TO 127 and TO 220 with 3 or more radial leads. Also different components (e.g. LED's) can be processed, which fit into the supply- shaft of the machine. The operation of the machine is restricted on filling up the exchangeable feed magazine with components to be processed. Optionally the machine can be equipped with a round- conveyor, to supply loose components automatically to the machine for processing. The tools are equipped with strain relief- valves to eliminate stress to the component body, when the leads are bend and cut. Once formed and cut the component is stored in a collection bin, seperated from shavings. The tool- change for different forms takes less than 5 minutes. Components

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Containers - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification using a rotary feeder - Container transport using pucks for flexible production and fast conversion - Container transport without pucks possible - Cycled container transport - Very gentle processing of the containers - Processing different container shapes Shapes -User-friendly, fast and primarily tool-free format change Design - Simple assembly (plug and play) - low installation costs - Good visibility and accessibility - Compact design with low space requirement - Compact design with integrated control cabinet - Secure and sturdy mechanical system Drive - Drive via wear-free servomotors Manufacture/Closing - Positioning the caps manually for semi-automatic processes - Closing systems coordinated to the product

OPTIMA CONSUMER GMBH

Germany

- Compact construction - Product contacting parts can be made to customer specifications - Freely programmable filling nozzle movement and filling speed - Fully automatic cleaning process (CIP) Standard - CIP/SIP possible as option - Product feed via pressure vessel, pump, gravity or customer’s feeding system - Maximization of performance through double track container transport with the same number of filling positions - Tool-free, operator friendly format change - Modular design: product guiding components completely exchangeable by means of module wagon simply and quickly (avoiding cross-contamination) - Vapor extraction possible - Explosion-proof execution optional - In the case of container leakages, wet cleaning of the machinery, there is no carryover into the machine sub-structure, due to welded seal, inclined machine cover - Hot filling possible - Multi-component filling possible for diverse volumes

Do you sell or make similar products?

Sign up to europages and have your products listed

HELANTEC GMBH

Germany

The RAPIDE L200 is based on the HELANTEC fastfill technology and is the entrylevel model of the RAPIDE L series. The capacity with one filling line is approximately 300 units1). It is equipped with modern, progressive technology and enables efficient gas filling with reliable gas concentrations. This is measured continuously during the entire filling process via an integrated gas analyser. As soon as the set gas concentration is reached the filling process is ended automatically. Synchronisation of the filling and suction process also enables troublefree filling of large IG units. The handy device is well suited for changing implementation sites. The HELANTEC RAPIDE L200 also convinces with its extremely favourable priceperformance ratio. Are you looking for higher capacity and shorter cycle times? If so, consider our gas filling systems, RAPIDE L500 and RAPIDE L900.

Request for a quote

ASSFALG GMBH

Germany

The trough vibratory finishing machines are ideally suited for elongated individual parts and small series. Their advantages lie in the machining of heavy, bulky as well as long workpieces and in the contact-free working of sensitive individual parts in chambers. A soundproof cover reduces the noise level and makes working in a workshop possible. The clockwise and anti-clockwise rotation as well as the speed control from 1,200 to 1,500 rpm ensure a wide range of machining options. The unmanned working process is rounded off by the programmable timer. The system can be expanded with an optionally available paper filter and separator. For simple and convenient water treatment, we recommend a paper filter or a fully automatic water treatment system. The process water is pumped into the trough in doses and cleaned in the return flow via a filter fleece or the centrifugal force.

Request for a quoteResults for

Automatic process - Import exportNumber of results

20 Products