- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- all forming

Results for

All forming - Import export

EWG E. WAGENER GMBH

Germany

Tantalum is a shiny grey, very hard and yet ductile heavy metal from the vanadium group, it is easy to form and weld. Tantalum belongs to the refractory metals, is very resistant to almost all acids (except hydrofluoric acid) and has a high absorption capacity for hydrogen and nitrogen. In nature, tantalum only occurs bound together with niobium. Tantalum is used in electrical engineering, chemistry, in high-temperature furnace construction, in evaporation plants and even in nuclear technology. Tantalum is added as an alloying component to rust and acid-resistant steels. Tantalum carbide is used for the production of hard metals. At E.WAGENER you can obtain tantalum in all common forms, alloys and processing forms, always in accordance with your requirements.

Request for a quote

KRÄUTERHAUS SANCT BERNHARD KG

Germany

B-vitamins are of special importance for the human body. The B-vitamins are summarised in the so-called vitamin-B-complex. Among others, they are important for the nervous system, a normal mental role, the metabolism, the mucous membranes and the skin. All B vitamins form a group that can fulfil their metabolic tasks together.

Request for a quote

HPM TECHNOLOGIE GMBH

Germany

Our SAMNOS fluids are almost 100% biologically degradable fluids that do not require labelling. No work-related dermatological illnesses have occurred to our knowledge. The lubricity is very high, and it has a very effective cooling ability. All SAMNOS fluids form a thin, water-soluble film that protects against corrosion. SAMNOS ZM-22W is a universal cooling lubricant that can be used with almost all materials and machining processes and evaporates up to 95% residue-free.

Request for a quote

HPM TECHNOLOGIE GMBH

Germany

Our SAMNOS fluids are almost 100% biologically degradable fluids that do not require labelling. No work-related dermatological illnesses have occurred to our knowledge. The lubricity is very high, and it has a very effective cooling ability. All SAMNOS fluids form a thin, water-soluble film that protects against corrosion. SAMNOS Standard is a processing medium that evaporates up to 97% residue-free. This fluid can be used with all materials, including plastic. Due to the special cooling properties of the fluid, SAMNOS Standard is used especially with very demanding machining processes.

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

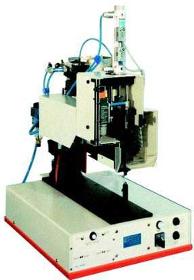

TYP A 042 Round pin inserter Description The Streckfuss inserting device Type A 042 offers the economical solution, for the mechanised insertion of round pins, solder posts and or - lugs into p. c. boards. With this device, nearly all customer forms of round pins, solder posts / - lugs can be processed. The loose components are filled into the sorting pot of the vibration conveyor. Trough barriers in the helical of the conveyor, the components are ordered. After positioning, the components are handed to the loading slider, which supplies the components to the inserting tool. Working with this device is save and easy: For assembling, hold the p. c. board with both hands on the edges, and place it under the inserting tool. The p. c. board now lies at the bottom of the pressure stamp, while the tooling pin hole is placed directly under the solder post / - lug shaft looming out of the inserting tool. This has the function of a locating pin. The p. c. board is lifted parallel, so the components shaft enters the tooling pin hole. The insertion process is triggered by a foot switch. Components

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 069/G Cutting, stamping and bending device for radial components Description To eliminate belt- tolerances the Streckfuss machine Type C 069 G was developed with an integrated touch- facility. With this all usual in the trade component- belts which meet the IEC- Norm can effortless be processed. The component is formed and cut with a maximum tolerance of ± 0,1 mm. The supply of components is exclusively done by reel. For this the machine has a combined location for reel and amo- pack. To save set- up time all necessary toolkits for specific formings are mounted in one unit. These toolkits can be inserted or exchanged within a very short time. When inserting a toolkit the driving- mechanism automatically will be locked. The machine is prepared to keep 2 processing- units. One unit performs upward formings and the other performs downward formings. After the components have been formed and cut they are ejected into a bin for collection. Components

Request for a quote

F. ZIMMERMANN GMBH

Germany

The FZ 30 and FZ 35 Portal Milling Machines are the economical solution for a vast variety of tasks. For finishing, and with the FZ 35 even roughing of steel and cast alloys, light alloys and plastics, these machines can be used for all types of materials*. This model range satisfies the sector-specific requirements of many industries. - In pattern and mold making for machining patterns, molds, injection-molding dies and sheet-metal forming tools in all their variety. - Outstanding capacity utilization, because different parts can be set-up at the same time and then machined in succession – of course in unmanned shifts as well. - In aircraft production for the trimming of panels, stretchforming parts, rudders etc., or for special applications of acrylic sheet, cockpit canopies for example. - In ship and boatbuilding for the manufacture of laminating forms, deck structures etc.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The FZ 35 Portal Milling Machine is the economical solution for a vast variety of tasks. For finishing and roughing of steel and cast alloys, light alloys and plastics, these machines can be used for all types of materials*. This model range satisfies the sector-specific requirements of many industries. - In pattern and mold making for machining patterns, molds, injection-molding dies and sheet-metal forming tools in all their variety. - Outstanding capacity utilization, because different parts can be set-up at the same time and then machined in succession – of course in unmanned shifts as well. - In aircraft production for the trimming of panels, stretchforming parts, rudders etc., or for special applications of acrylic sheet, cockpit canopies for example. - In ship and boatbuilding for the manufacture of laminating forms, deck structures etc.

Request for a quote

PROFILMETALL-GRUPPE

Germany

Roll forming of all sheet metal materials such as steel, aluminum, stainless steel, copper, titanium, molybdenum, pre-painted materials, composite materials from 0.08 mm material thickness.

Request for a quoteResults for

All forming - Import exportNumber of results

10 Products