- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air gas

Results for

Air gas - Import export

BÜRKLE GMBH

Germany

The withdrawal system can be used to dispense high-purity liquids quickly and without complications. An excess pressure is produced in the container with pressurised gas (compressed air or nitrogen), thereby pumping the liquid out of the tank. The advantage of operation using pressure gas is that the user can extract even large amounts without effort while having both hands free to dispense the solvent. In this way, large amounts of hazardous media such as acetone, ethanol and methanol, etc. can also be safely dispensed and accurately metered using the stop cock. For use with media sensitive to oxygen or for ultra-pure media, operation with an inert gas (e.g. nitrogen) is possible. The barrel screw connection and shut-off valves seal off the barrel and pump hermetically. This means that no vapours containing solvents can escape after dispensing, thereby protecting users' health and the environment.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

We develop and manufacture Venturi tubes and nozzles as individual components or as complete VMF® systems. The VenturiMasterFlow® measuring system, VMF® for short, is used for the precise measurement of air or gas volume and mass flows 100,000 m³/h The flow measurement by means of a Venturi tube or Venturi nozzle is characterized by high measuring accuracies up to 0.5% MW and a fast response time < 10 ms. A further benefit is the high long-term stability of the measuring element.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

We offer you standardised complete systems for the measurement of volume & mass flows. We use measuring elements that have established themselves within previously built customer-specific test benches and convince with high measuring accuracy. We develop and manufacture Venturi tubes and nozzles as individual components or as VMF® complete systems. The VenturiMasterFlow® measuring system, VMF® for short, is used for the precise measurement of air or gas volume and mass flows of 100,000 m³/h. The core of the VMF® system is the FlowProcessor, a PC system with the corresponding data acquisition hardware. Venturi nozzles convince by a low remaining pressure loss and are suitable for flow measurement of gases with high temperatures. The software developed under LabVIEW is operated either via touch screen or with mouse and keyboard.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Mixor™ is a precision compressor-carburetor device which accurately mixes gas and air in any selected ratio, and compresses it for use with endothermic cracking, or exothermic cracking generators, or as a source of pre-mixed gas and air for torch brazing, flame heat treating, or sort metal melting.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

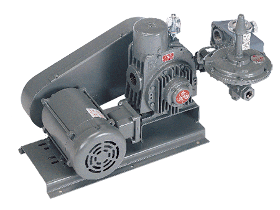

Gas Mixing Panels include the Waukee brand rotary vane compressors, air and gas Flo-Meters, and either a mechanical carburetor or RatioProver for precise ratio control. Panels are available with additive trim gas or air Flo-Meters. FEATURES: • Available with Lubed Vanes (includes a set of Phenolic Vanes and an Auto Lubricating System) or Non-Lubed Vanes (includes a set of Long Life Composite Vanes) • Available with outlet pressures ranging from 0.5-5.0psig. For higher pressures, consult UPC. • Two options available for ratio control: Standard Carburetor, RatioProver • Available with output capacities ranging from 200-12,000CFH • Available with Built-in Unloader for pressures between 0.5-2.5psig or with Bypass Relief Regulator for pressure lower than 0.5psig or higher than 2.5psig • Available with Standard turndown of 2:1 or 10:1 when used with a Compressor Pressure Controller • Includes Gas and Air Flo-Meters and Air Filter • Available with Trim Gas or Air Flo-Meters

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DIENER ELECTRONIC GMBH & CO. KG

Germany

A cost-effective process for activating plastic and elastomer surfaces is treatment with the APC500. Using air as the process gas, large surfaces can be activated under atmospheric pressure. An arc is ignited between two electrodes in an inhomogeneous field. The voltage is about 10,000 V. In the discharge zone, the air flowing through is ionised. The plasma is blown out of the electrode area by the air flow. The substrate can now be treated in the emerging corona. A strip several centimetres wide is treated in the corona. With several parallel plasma generators it is possible to treat surfaces. Due to dangerous voltage potential, PlasmaAPC 500 is only suitable for non-conductive materials. PlasmaAPC 500 is suitable as a pre-treatment unit for the following processes: Bonding, printing, painting. The following surfaces can be treated with PlasmaAPC 500: Plastics, rubber, ceramics, glass.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

A cost-effective process for activating plastic and elastomer surfaces is treatment with the PlasmaAPC 500 DUO. Using air as the process gas, large surfaces can be activated under atmospheric pressure. An arc is ignited between two electrodes in an inhomogeneous field. The voltage is about 10,000 V. In the discharge zone, the air flowing through is ionised. The plasma is blown out of the electrode area by the air flow. The substrate can now be treated in the emerging corona. A strip several centimetres wide is treated in the corona. With several parallel plasma generators it is possible to treat surfaces. Due to dangerous voltage potential, PlasmaAPC 500 DUO is only suitable for non-conductive materials. PlasmaAPC 500 DUO is suitable as a pre-treatment unit for the following processes: Bonding, printing, painting. The following surfaces can be treated with PlasmaAPC 500 DUO: Plastics, rubber, ceramics, glass.

Request for a quoteResults for

Air gas - Import exportNumber of results

8 ProductsCompany type