- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stainless steel welding

Results for

Stainless steel welding - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

They are the pipe made by stainless steel 304,mainly use for the connector.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts used for mechanical .

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine for belt grinding and polishing stainless steel weld seams. Belt grinding on the contact wheel or slack belt unit is possible for edge profiling.

Request for a quote

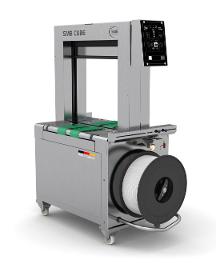

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Economical owing to highest availability Robust and extremely low maintenance Easy handling Minimum space requirement Stainless steel configuration ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 12 mm, either DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable Upstream and downstream interlocks Conveyor speed steplessly adjustable Belt type or roller conveyor Stainless steel welding plate, low maintenance GreenTech energy concept, low power consumption High-Speed-Kit, optional Intuitive operator interface MFT 'Mono-Frame-Technology' Bundle press, optional SAO 'Safe and Open' - Safe without protection doors Bundle flow control Wear-free, energy saving direct-drive-motors Low maintenance and low wear strap arch Many specific options available, easily configurable

Request for a quote

BDP MECHANICAL COMPONENTS DEUTSCHLAND GMBH

Germany

Made by cold forging, machining and welding, material stainless steel, sizes 250mm x 50mm x 15mm, weight 0,5kg, annual demand 800pcs

Request for a quote

MINEBEA INTEC GMBH

Germany

The MP 55 Platform Weigh Cell is made completely from stainless steel, is available in a load range from 11 kg to 200 kg and platform sizes up to 600 mm x 600 mm. It is specially designed for integration into beltweighers, counting scales and checkweighers. Protection class IP68, IP69K Full stainless steel construction Hermetically welded seal (IP68, IP69K) Platform size up to 600 mm x 600 mm Approved to OIML R60 Ex-Version available (MP55/...E) High Input Impedance Integrated Mounting spacer

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The Autovent 3000 ensures optimal cooking processes at smallest weight loss without any fans at all! Instead, the system's patented nozzles use the internal dynamics of lowpressure steam, converting it into air speed and heating energy. For you, this means Shorter cooking times and weight loss reduced by up to 15%! High turbulences due to patented AUTOVENT nozzles and air velocities of up to 200 m/s Short cooking times and up to 15% less weight loss Temperature difference across the system no more than 1 °C Uniform products at highest quality Very low maintenance and operation costs from dispensing with fans Long service lives from stainless steel construction and steamtight welding allround

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

TECHNOLOGICAL INNOVATION OPENING UP NEW MARKETS The new automated Lipp welding process will again shake up tank construction market just as the well established Lipp double fold system did decades ago. It is a perfect combination of the long experience in metal forming and state of the art welding technology. KEY BENEFITS OF THE LIPP WELDING TECHNOLOGY Automated welding proces, on site Visual weld monitoring and technical documentation Reinforcement ribs for enhanced structural stability and reduced material costs High quality and repeatability Fast installation Choice of different material grades and types CERTIFICATES SPECIFICATIONS OF THE LIPP WELDING TECHNOLOGY BLACK STEEL SPECIFICATIONS OF THE LIPP WELDING TECHNOLOGY STAINLESS STEEL Beside black steel, various grades of stainless steel and duplex steel can be auto welded. In addition to the new potential markets and applications, the Lipp automated welding technology will increase the competitiveness

Request for a quote

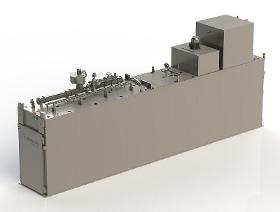

FESSMANN GMBH UND CO KG

Germany

The TFi3000 Autovent is a true efficiencywonder! The patented procedure for lowpressure steam cooking without any fans at all, in combination with automated work processes, reduces the operating costs to a minimum. Cooling of the products in the closed system, directly subsequent to heat treatment, also ensures ideal hygiene conditions and increases durability. Production justintime, controllable process with reproducible work processes Automatic transport system Much lower germ formation and contamination – for longer durability Short cooking times and weight loss reduced by up to 15% Temperature difference across the system no more than 1 °C Uniform products at maximum quality due to turbulences and air velocities up to 200 m/s Very low maintenance and operation costs thanks to dispensing with fans Long service lives due to stainless steel construction and steamtight welding allround

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The force to be measured must be introduced axially and perpendicularly to the entire surface of the inner and outer bands of the sensor in the opposite direction. Conversion of the acting force into an electrical output signal is performed by strain gages connected together in a full bridge circuit. To achieve optimal accuracy, the base of the sensor should rest on a smooth level surface, hardened to at least ≥ 58 HRC with sufficient dimensions. The base cover welded to the surface has a stabilizing effect on the sensor element. Lateral forces must be avoided anyway as they distort the measured results. Tension and bending relief for the sensor cable is to be carried out on the machine side. FEATURES: — Measuring ranges from 0 ... 100 N to 0 ... 200 kN — Centric throughout hole — Flat disc design — Made of stainless steel — Completely welded sensor body — Nominal characteristic value standardization possible — burster TEDS optionally available

Request for a quote

BDSENSORS GMBH

Germany

The industrial pressure transmitter DMP 335 is based on a stainless steel welded pressure sensor without fluid. This characteristic has a special advantage with applications where silicon oil or elastomeric seals cannot be used. Features: — nominal pressure: 0 ... 16 bar up to 0 ... 600 bar — accuracy: 0.5 % FSO — suitable for oxygen applications — insensitive to pressure peaks — high overpressure capability Optional Features: — IS-version Ex ia = intrinsically safe for gases and dusts — customer specific versions

Request for a quote

BDSENSORS GMBH

Germany

Compact OEM Pressure Transmitter Heavy Duty Applications: ► mobile hydraulic, presses ► general mechanical engineering Characteristics: ► stainless steel sensor, welded ► accuracy according to IEC 60770: 0.5 % FSO ► nominal pressure ranges from 0 … 16 bar up to 0 … 600 bar

Request for a quote

BDSENSORS GMBH

Germany

The battery-powered BAROLI 02P enables a local displaying of values in applications, where high requirements on hygienic process connections and easy cleaning or sterilisability are requested. The filling medium is food compatible oil with FDA approval. The display housing is rotatable, thus ensuring an easy reading even under unfavorable mounting conditions. Additional functions: switching the unit, displaying min / max values, calibrating the offset and the end point, configuring the automatic switching-off. Features: — nominal pressure: 0 ... 100 mbar up to 0 ... 40 bar — accuracy: 0.125 % FSO BFSL (class 0.1) — 2-line LC display, 4.5-digit 7-segment display, 6-digit 14-segment add. display — hygienic process connections, EHEDG — flush welded stainless steel diaphragm Optional: — min/max function with reset function — offset and end point calibration — setting the pressure unit — configuration of switch-off automatic

Request for a quote

BDSENSORS GMBH

Germany

The BAROLI 05P enables a local displaying of values in applications, where high requirements on hygienic process connections and easy cleaning or sterilisability are requested. The filling medium is food compatible oil with FDA approval. The display housing is rotatable, thus ensuring an easy reading even under unfavorable mounting conditions. Additional functions as changing unit, displaying min / max values, calibrating of offset and span, as well as configuring the automatic switching-off complete the profile. Features: — nominal pressure: 0 ... 60 bar up to 0 ... 400 bar — accuracy: 0.25 % FSO BFSL (class 0.2) — flush welded stainless steel diaphragm — rotatable housing — 2-line LC display, 4.5-digit 7-segment display, 6-digit 14-segment additional display — suited for viscous and pasty media Optional Features: — min / max function with reset function — offset and end point calibration

Request for a quote

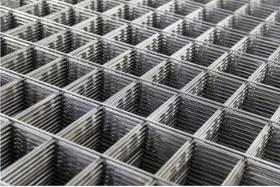

WDM DEUTENBERG GMBH

Germany

The central product of WDM Deutenberg are spot-welded wire meshes according to individual specifications. There are four different wire materials used to produce our wire meshes and wire mesh elements: bare wire, galvanized wire, aluminium galvanized wire and stainless steel wire. Our spot-welded wire meshes have different sizes from 300 x 250 mm to 8,000 x 2,400 mm depending on mesh width and wire diameters. Mesh widths between 20 mm x 20 mm minimum and 150 mm x 150 mm maximum and diameters from 2.0 mm to 18.0 mm are possible. The scope of application of our spot-welded wire meshes is very diverse. They are used in industries such as landscaping, agriculture, engineering, shopfitting, metalworking, food industry, electrical industry, construction industry or retail. Please call us for further questions under +49 (0) 38789 / 879-0 an or write us an e-mail to info@wdm-wolfshagen.de.

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

Safely carries single cables Where single cables are to be routed in a group and supported firmly without the use of trunking, the Single Wire System SWS from PFLITSCH offers a better alternative to cable ties, clamps, hoses or hook and eye fastener tape. Your advantages: Bendable VA stainless steel rod for robust, flexible cable routing support Corrosion-resistant system Easy to clean, open cable routing Easy installation with VA stainless steel or plastic mounts SWS consists of bendable and yet robust 5 mm support rods with open routeing rings into which the cable is simply laid. Lines and hoses up to 16 mm can be safely accommodated – on straight sections or around corners. The support rods are attached with bolted-on plastic mounting plates or VA stainless steel mounts welded on to the machine body for example.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KÖSTER & CO. GMBH

Germany

Stud welding equipment with capacitor discharge Suitable for welding steel, stainless steel, aluminium and brass Weldable stud range 3-8 mm stud diameter Continuously adjustable charging voltage Digital display of charging voltage Weight only 8,9 kg Steel housing, powder-coated

Request for a quote

EWM AG

Germany

Maximum operating convenience, long service life and all pulse, standard and innovative welding processes optimised and included in the machine at no extra charge. The members of the Titan XQ family are taking a quantum leap in welding technology. Here, perfect weld seams are already pre-programmed for low- and highalloy steels and aluminium in all material thicknesses and all positions. Thanks to the many options and accessories for the Titan XQ puls series, you can put together your machine in the way that best suits you, your needs and your applications. An exceptionally long duty cycle of 100% at up to 350 A, for example, makes for effective working. Perfect welding becomes sustainable – 24 hours a day, 7 days a week.

Request for a quote

EWM AG

Germany

Maximum operating convenience, long service life and all pulse, standard and innovative welding processes optimised and included in the machine at no extra charge. The members of the Titan XQ family are taking a quantum leap in welding technology. Here, perfect weld seams are already pre-programmed for low- and highalloy steels and aluminium in all material thicknesses and all positions. Thanks to the many options and accessories for the Titan XQ puls series, you can put together your machine in the way that best suits you, your needs and your applications. An exceptionally long duty cycle of 100% at up to 320 A, for example, makes for effective working. Perfect welding becomes sustainable – 24 hours a day, 7 days a week.

Request for a quote

RHODIUS ABRASIVES GMBH

Germany

Stainless steel fillet weld brush. V-shaped stainless steel wire inserts for optimum cleaning of hard-to-reach welding seams and fillet welds. • Accurate cleaning • Great cleaning performance • Especially effective for slag

ERNST WAGNER GMBH & CO. KG

Germany

Hygiene station consisting of a sensordisinfectant dispenser and a floorstand in stainless steel, visible surfaces satin finished and brushed. Sensordisinfectant dispenser in stainless steel (AISI316L); all corners fully welded. With touchfree operated disinfectant pump with 950 ml tank. Designed for standard disinfectants for hands. Inspection slot to indicate fill level. Accessible for refilling through lockable, hinged housing. Keyed alike cylinder lock in corrosionresistant zinc diecasting. Delivery includes batteries. Floorstand in stainless steel (AISI304) with rubber feet. Intended for free floor installation. Dimensions 380 x 1350 x 380 mm

Request for a quote

(STW) SENSOR-TECHNIK WIEDEMANN GMBH

Germany

The F02 has been designed for application in systems which require a pressure transmitter with a Performance Level PL d or a Safety Integrity Level of SIL 2. It has a thin-film measurement cell made from stainless steel which is welded together with the pressure sensor and thus guarantees high media compatibility. It is available within pressures from 10 to 1200 bar. The output signal is made available at two outputs in parallel, whereby the second output represents an inverted signal. Users can select between a ratiometric and an 4-20-mA output in three-wire technology. The permitted media temperature range extends from -40…+125 °C. The total accuracy in the compensated range of 0…+80 °C lies at <= 1 % FS. The possible flexibility during integration into an existing machine is ensured through the provision of a multitude of available pressure connections as well as the small construction. The electrical contact takes place via a 5-pole M12 connector. The F02 also has E1 approval.

Request for a quote

(STW) SENSOR-TECHNIK WIEDEMANN GMBH

Germany

The M01 series has been especially designed for applications in adverse ambient conditions in the same way value is placed on high resistance to aggressive media. Furthermore, the modular principle permits many combinations of pressure connection, pressure range, output signal and connector, so that the right sensor can be found for most applications. For pressure ranges from 10 to 2000 bar, which are frequently required for use on mobile machines, welded stainless steel measurement cells are used which are suitable for media temperatures from −40 to +150 °C. Depending on the type of measurement cell and the material coming into contact with the media, the M01 is resistant to aggressive/non-aggressive gases and liquids. On request, versions in 316L design for use in hydrogen pressure measurements are available. In addition to CE and UL certificates, every M01 product with a 1.4542 stainless steel measurement cell possesses an E1 approval verifying its suitability for use in vehicles.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS For clamp mounting into the pipeline Efficient protection of dirt-sensitive system components during commissioning Low differential pressure Easy installation and replacement Material Certificates DIN EN 10204/3.1 for Clamp Collar OPTIONS For DIN and ASME flange connections Design for low temperature down to -50 ° C Design pressure up to 100 bar Stainless steel construction Reverse flow direction GENERAL The starting screen VAS is used for commissioning and starting a system in order to clean gas from coarse soiling such as welding bead, scale, grease, etc. After starting, the starting screen can be removed from the pipeline. The design is carried out as a welding design. FUNCTION The starting screen VAS consists of a supporting basket made of perforated sheet metal with a welded clamping ring. These are galvanized after assembly. On the outside of the support basket a stainless steel wire mesh is welded.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK Förderband Technik Kilian GmbH has the second largest range of elevator buckets. With more than 400 bucket types and sizes, we have a bucket for every product and application. Elevator buckets in regular & stainless steel (deep drawn or welded) Synthetic elevator buckets (nylon, HDP or polyurethane) Elevator buckets for agricultural applications (e.g. grain, seed, mixed feed, sugar) Elevator buckets for industrial applications (e.g. cement, gypsum, aggregates, coal, artificial fertiliser)

Request for a quote

LABOM MESS- UND REGELTECHNIK GMBH

Germany

Diaphragm seal for food/pharmaceutical/biotechnology clamp connection per ISO 2852, DIN 32676 Features ■ Flush-mounted separating diaphragm of stainless steel, laser welded ■ Volume optimised diaphragm base ■ System fillings for different applications ■ Measuring device connection: - directly welded - directly screwed - with temperature decoupler - with capillary Options ■ Certificates - Material certificate acc. to EN 10204-3.1 ■ Electropolishing (wetted parts) ■ Hygienic design with advanced surface quality ■ Special materials upon request Application Suitable for mounting to bourdon tube pressure gauges and pressure transmitters. The diaphragm seal with clamp connection is used mainly for dead-zone free pressure measurement.

Request for a quote

LABOM MESS- UND REGELTECHNIK GMBH

Germany

Pressure transmitter COMPACT Features: Measuring ranges 0…250 mbar up to 0…100 bar Linearity error including hysteresis <+ 0.2 % f.s. Piezoresistive measuring system Hygienic design according to EHEDG, FDA and GMP recommendations Material and surface quality according to the hygienic requirements Wetted parts of stainless steel; completely welded Stainless steel housing as standard or field housing Degree of protection IP 65, IP 67 option Output signal: 4…20 mA Process temperature up to 200 °C Options: Explosion protection for gases Classification per SIL 2 Inspection certificate: material certificate as per DIN EN 10204-3.1

Request for a quote

LABOM MESS- UND REGELTECHNIK GMBH

Germany

This bourdon tube pressure gauge with switch function (electrical contact device) has been especially constructed for the operation with diaphragm seals. A custom bourdon tube that is reduced in volume produces a very slight temperature error. Diaphragm seals with reduced diaphragm surface areas may also be used. A large selection of LABOM diaphragm seals is available for a variety of applications. Bourdon tube pressure gauge for diaphragm seal and switch function Nominal range -1…3 bar to -1…15 bar, 0…4 bar to 0…400 bar High quality case with bajonet ring NS 100 Case, measuring element and pressure connection of stainless steel Instrumention connection welded with diaphragm seal Small temperature error by means of reduced-volume measuring element Process connection via diaphragm seal product group D5 Electrical contact device per DIN 16085 EAC declaration

Request for a quoteResults for

Stainless steel welding - Import exportNumber of results

57 ProductsCountries

- Germany (57)

- Berlin and region (1)

- Bonn, Düsseldorf and North Rhine and Westphalia (29)

- Frankfurt am Main and Hesse (3)

- Hamburg and region (1)

- Hannover and Lower Saxony (3)

- Mainz and Rheinland-Pfalz (3)

- Munich, Nuremberg and Bavaria (8)

- Potsdam and Brandenburg (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (7)

- Weimar and Thuringia (1)

Company type

Category

- Pipe and tube fittings - ferrous metal (23)

- Measurement and regulation equipment and instruments - electricity and other energy (4)

- Welding work - steels and metal (2)

- Cooking and smoke-curing equipment for delicatessens (2)

- Manometers (2)

- Measurement and regulation equipment and instruments - pressure (2)

- Stainless steels (1)

- Tanks, metal (1)

- Steels and metals - welding and brazing (1)

- Agricultural machines and accessories (1)

- Automatic dispensers (1)

- Cable ducts (1)

- Forming - steels and metals (1)

- Gratings, metal (1)

- Houseware, steel (1)

- Measurement - Equipment & Instruments (1)

- Polishing - machine tools (1)

- Sensors (1)

- Spraying equipment, agricultural (1)

- Tools, pneumatic (1)