- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special filters

Results for

Special filters - Import export

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Special solutions for extraction from one or more sources of emission, designed and manufactured in accordance with special customer requirements. Special filters Special filter systems are designed for extraction from one or more sources of emission. We design and manufacture them in accordance with the special requirements of our customers. These filters are usually based on our own proven designs, which we then specially modify. Special applications or special solutions implemented: Special versions:

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

Special FTJ filter fleeces are particularly suitable as precoat or support fleece on horizontal plate pressure filters or plate filters The following precoat agents are used: Diatomaceous earth Bleaching earth Cellulose Cornmeal The FTJ nonwovens Cora®Dot and Cora®Spun effect corresponding savings on precoat agents with extremely fine filtration.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Oil mist separator Best possible protection against oil and spray mist Clean air – always With our special filter system EONA 3000 you efficiently remove oil mist and oil vapour emitted during lubrication procedures to maintain high air quality at the machine and place of work. Features & benefits • High separation efficiency thanks to the integrated F9 class filter • Several filter stages, which ensures the last filter stage enjoys a particularly long service life • Installed in a sturdy sheet-steel housing • Various “docking sizes” for suction hoses • Controllable ventilator (including remote control) Design versions and details The extremely sturdy filter system EONA 3000 is designed for horizontal extraction. We offer this product suitably sized for all working environments. The extraction capacity of the EONA 3000 is 3000 m3/h. The separated oil is collected or is allowed to drain. An electrostatic extraction filter is available as an optional extra. Moreover, the system is a

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

The requirements for reliable filter technology are extremely diverse. KOPP is responding to this with a comprehensive range of reliable filter devices. Special designs are also possible. Filter devices Wide range of products for every need Drinking water is supplied by the waterworks clean and without contamination. However, on its way through the extensive network of pipes, water can pick up dirt particles, which cause unpleasant malfunctions and operational interruptions and thus cause costly failures, for example in machines, pumps, valves or household appliances. By installing a filter, you ensure that disruptive particles are retained. This way you avoid operational disruptions and expensive repairs. The requirements for reliable filter technology are extremely diverse. KOPP is responding to this with a comprehensive range of reliable filter devices. Special designs are also possible. Individual solutions for every need – that’s KOPP. Also in the area of filter technology.

Request for a quote

MICRO-EPSILON

Germany

The optoNCDT BL models are equipped with a blue laser diode and are used when standard sensors with a red laser diode are operating at their performance limits. Due to its shorter wavelength, the blue laser does not penetrate the target surface, projecting a small light spot on the surface and therefore providing stable and precise results. As Blue Laser sensors are equipped with a special filter, they are insensitive to highly emitting objects such as glowing metals. Blue Laser sensors are preferably used with measurements on organic and (semi-)transparent objects, as well as for red-hot glowing metals.

Request for a quote

DEUTSCHES METALLFASERWERK DR. SCHWABBAUER GMBH & CO. KG

Germany

Material: 1.4113 (X6CrMo17-1) AISI 434 Properties: heat-, corrosion- and acid-resistant, magnetizable We produce our STAX stainless steel fibers 1.4113 in the grades coarse with an average fiber strength of approx. 120 μm, medium 90 μm, fine 60 μm and on demand extra fine 30 μm. STAX Edelstahlfasern 1.4113 are available as following: Strand on reels with defined weight per meter and a width of 100 mm Short fibers according to customer requirement Fleece on bales with defined weight per square meter Applications for STAX stainless steel fibers 1.4113 are for friction material as in brakes pads, further as filter material or special round filters (as well in half-round version, see photo), sound damping or -insulation. If you are looking for stainless steel fibers for your specific application, please do not hesitate to contact us.

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

We adapt our filter bags exactly to your specific requirements and thus create the highest process reliability for you. FTJ filter bags are available in sewn and welded design, with plastic collar and stainless steel ring. We offer standard filter bags, high performance filter bags and absolute rated filter bags. High performance filter bag made of needle felt in PP or PES (welded/sewn version) Longer lifetime Higher dirt absorption capacity Fully welded seams Special bag filter seal Full compatibility with the entire FTJ filter housing program Production according to the highest quality standards

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST XXL+ is a large state-of-the-art xenon flatbed instrument. The 3000 cm2 test chamber is perfect for high volume weathering testing of large flat or 3-D specimen. SUNTEST XXL+ offers a complete set of features ideal for standard testing covering all common industry weathering standards. 3x 1700 W air-cooled Xenon Lamps 3000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Measurement and control of Irradiance 300-400 nm / 340nm or 420nm Measurement and control of Black Standard (BST); (Black Panel optional) Measurement and control of Chamber Temperature Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test method Multilingual User Interface Control Panel tiltable for increased operating comfort Ultrasonic humidification system for humidity control Specimen spray system with integrated 60 l water reservoir Static, horizontal exposure area for flat or 3D specimen Test chamber with 5 ° slope for optimum spray water drain Access port ca. 3,0 x 2,5 cm for potential use of additional external sensors inside the test chamber Light cassette including non-ageing aluminium reflector, coated quartz filter and slot for additional optical filters Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Various specimen holders to hold different panel sizes. XenoCal sensors to calibrate BST and irradiance. Large variety of filter systems: coated and uncoated quartz, special UV glass, daylight filter, window glass, Solar ID 65, Solar Standard, to meet various spectral specifications in standards.

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

For forced drying. Drying rooms Drying rooms offer the possibility to make the drying process faster and more comprehensible through forced drying. Depending on the paint systems, the temperature and humidity of the air can be adapted to suit the special requirements. In the high-gloss field in particular, special filters ensure the demanded degree of purity. Depending on the size and the specific task, Rippert also offers its drying rooms with heat recovery.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Standard advantages: RTS-Rotation – low-maintenance dry spray booth Overspray dry separation demonstrates its strengths in practice above all when relatively large quantities of paint have to be processed and the overspray portion cannot be reduced any further. Spray booth with dry separation are usually equipped with disposable filters or manually regenerative filters. These cause costs for spare filters, maintenance and disposal. In addition to that, operation has to be interrupted in order to exchange the filters. The ‘RTS rotation’ system was developed by Rippert in order to reduce these costs and tooling times. Maintenance intervals and filter service lives are prolonged significantly in comparison with conventional systems due to the new brush pre-filtration. How the ‘RTS-Rotation’ system works Overspray separation in the RTS-Rotation system takes place by means of a pre-filter and a fine filter stage. The pre-filter stage is formed by vertical, slowly rotating brush rollers. The bristles present a very large total surface area and absorb the adhesive particles from the overspray. During the slow rotation, the paint particles can dry on the tips of the bristles. This results in slowly growing cakings on the bristles. Scrapers are mounted in the area behind the brush rollers that continuously remove these cakings from the bristles. The dislodged, hardened material falls into the drawers arranged under the brushes and can thus be simply disposed of. The dry paint dust may often be disposed of as ‘commercial waste’. The brushes otherwise require little maintenance and do not need to be exchanged or renewed. The fine filter stage is formed by a special fleece filter, which is arranged above the brush rollers and must be manually maintained or exchanged in the standard version. The maintenance intervals depend on the paint material used. Automatic cleaning or an external fine filter with automatic cleaning is also possible as an option. Over 10 years of operational experience shows that around 75 to 95% of the overspray is separated out by the pre-filter stage and the rest by the fine filter stage. The degree of separation depends strongly on the type of paint and the drying reactivity during the flying phase. Use of the RTS-Rotation with the following paints Before practical use, the paints are tested and approved in Rippert’s own pilot plant. Stove enamels and 100% UV paint systems cannot be used. The horizontal version Furthermore, it is possible to use the system as a horizontal underfloor extraction system. This version is used, for example, by a machine manufacturer for large parts. In addition, a drag conveyor with gulley extraction is used there in order to automatically transport the particles cleaned off the brushes out of the pit. Conclusion The RTS-Rotation system is particularly useful when relatively large quantities of paint with an unavoidable overspray portion have to be processed, as otherwise a great deal of residual waste would result using conventional technology. Compared to water-sprinkled spray walls and normal dry spray booths the amortisation period is shorter; it is frequently less than two years.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

With high-quality filter tubes and PTFE diaphragms. Paint dust filters Wet painting also results in overspray. Overspray is the solid portion of the paint that is not taken up by the workpiece. According to the purpose of use, the overspray is moist and sticky immediately after release. It is captured by the exhaust air stream in the spray booth and fed to a filter. This can be, for example, a baffle plate filter, paper filter, fleece filter, glass fibre filter or also combinations of these. The adhesive effect causes the paint particles to adhere to the contact surfaces of the respective filter medium, as a result of which a good degree of separation is achieved. However, all these filters are storage filters, i.e. the filters clog up more and more during operation and cannot be regenerated. A filter exchange becomes necessary if the exhaust air rate of the spray booth falls below the minimum. This can be very time-consuming under certain circumstances and the work process must be interrupted in order to do it. To make things worse, not only must the filtered and bound paint residues be disposed of, but also the actual filter materials. Such tooling times are not justifiable for automatic, continuous or multi-layer painting processes. Continuous procedures such as automatically cleaned filters are likewise required for this. The humidity and the adhesiveness of the particles to be filtered are thereby the problem. In order to solve this problem, the paint particles should be relieved of their adhesive capability as far as possible whilst still inside the paint booth. Our patented ‘RTS-Rotation’ system is outstandingly well suited for this. The system is comprised of slowly rotating brush rollers, which take up the adhesive paint particles on the surface of the bristles and allow them to dry there. The bristles are automatically regenerated at pre-specified time intervals by combing devices that swing in at the rear of the brush rollers. The dislodged paint residues can then be removed and disposed of either manually during work breaks or automatically during operation. The degree of separation of this system is, however, insufficient to satisfy the environmental protection requirements concerning residual dust content in the exhaust air. A further filter stage is necessary for that. It must be assumed that the paint particles arriving here are to a certain extent still damp and sticky. For this we use special paint dust filters with high-quality filter tubes with PTFE diaphragms. If necessary, precoating agents (auxiliary dust) are used in order to neutralise the adhesive capability of the particles and to keep the dust layer on the filter elements permeable to air. The precoating agent is injected into the raw air pipe by means of special dosing units. The filter tubes are cleaned by means of compressed air impulse cleaning. The use of this technology requires special know-how. We have had the appropriate experience for almost ten years. The implemented plants have capacities ranging from 5,000 to 90,000 m³ /h. Because of the large number of different paint systems, individual experiments are usually necessary in our pilot plant in order to find the correct solution for the individual case.

Request for a quote

STRONG MAGNETS GMBH

Germany

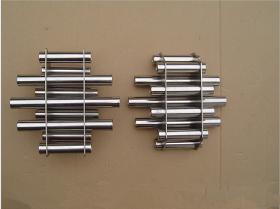

Scope of application Magnetic filter rod (magnetic rod) is mainly used to remove ferromagnetic impurities in powder, granular and liquid or slurry. It is widely used in ceramics, power, mining, plastics, chemical industry, rubber, pharmaceuticals, food, environmental protection, pigments, dyes, electronics, metallurgy and other industries. Working Principle The magnetic rod is made of high quality stainless steel pipe and high B value rare earth alloy NdFeB, and is made by special manufacturing method. The magnetic filter can be assembled on a fixed frame to form a magnetic filter. When the material containing iron passes through, it is attracted by the magnetic rod, and the material containing iron is firmly adsorbed on the wall of the magnetic rod. To ensure the integrity of equipment and product safety. Product features energyfree, pollutionfree, can be installed in any position on the production line with material contact, saving space, easy installation.

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

Application To avoid measurement errors and damage by foreign objects carried in the medium. Reliability Complete emptiying of conical design and drain plug at the lowest point of the filter (filters in cast). Special features Low pressure drop due to large filter surface area (up to 16 times the pipe crosss-section) Flexibility • DN15 to DN400 • -200 °C to +300 °C • to 3.000 m³/h • to PN100 • different materials

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

"The dual channel IR thermopile for NDIR gas analysis of halothane (C2HBrClF3) with a CWL of 7665 ± 77 nm and a HBW of 242 ± 40 nm. The signal strength is of the high sensitivity IR detector is comparable to that of a pyro detector: high detectivity up to 6.27*10^8 cm√Hz/W and high sensitivity up to 171 V/W. These values can be achieved by filling with krypton. The MTS2SENS200 halothane provides reliable readings in environments between -20 and 85 °C, e.g. for anesthetic gas monitoring. The interference absorber, an integrated thermistor for reference temperature determination and the reference channel (CWL: 5060 ± 25, HBW: 100 ± 15 nm) are further important product features for long-term use in demanding medical applications. Two sensor chips with 200 BiSb/Sb thermocouples each form the basis of this premium detector. The narrow-band optical filter windows are specially adapted to the analysis of target gases in the application.

Request for a quote

KASPAR SCHULZ BRAUEREIMASCHINENFABRIK & APPARATEBAUANSTALT GMBH

Germany

Beer loss and oxygen intake are reduced to an absolute minimum, making the SCHULZ filtration system attractive even for small-scale brewers. A continuous dosage of filtering aids (cellulose and/or perlite) ensures that the permeability of the candle and flexibility with fluctuations in the filter inlet are maintained. Furthermore, the use of a downstream particle filter is rendered obsolete thanks to special depth filter cartridges. For operating batches of more than 10,000 hl, the service life of the filter can be increased, as is shown in the unit pictured here, by a separator and adjoining buffer tank. The modular design allows for a gradation of the filtration capacity in a 15 hl/l increment. • Kieselgur-free precoat filtration • Capacity of 15 hl/h/module • Built-in CO2 nozzle cuts down on oxygen intake • Flexibility with regard to different unfiltrate conditions • Dosage vessel can also function as CIP & sterilization tank for the filter • No downstream

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

ZPZ – VPZ 240°C-Filterelemente (Finalfilter) for cellular gas filters: ZPZ 25 – ZPZ 50 – ZPZ 80 – ZPZ 100 – ZPZ 150, type FFX Efficiency: 99,9 > 1µm In the area of fine dust separation, the gas is cleaned with filter cartridges. Our filter cartridges are all tested according to ISO 12103-01 and proven to be efficient, according to the requirements of the internationally valid “Test Aerosol: SAE-Fine Test Dust”. For special fields of application we can offer and develop special filter elements in order to achieve a performance-fulfilling filtration.

Request for a quote

PH-CLEANTEC GMBH

Germany

Mobile. Parts cleaning collector with sturdy drip-off grid, 80 kg load capacity, 30l. Water recycling via special sedimentation system with filter monitoring. 60 l water tank, 5 l cleaning agent reservoir, stepless adjustable pressure, metering device for cleaning agent, water shortage control, overheat fuse. Volume 2,8 l /m. 15 KW, 32A. With closed parts cleaning cabin in stainless steel, incl. vapour exhaust system, integrated light and compressed air supply. Access via brush curtains. 5 m hose with large pistol, hand screw coupling and lance SR-LA 600, 1 m hose with small pistol, quick change coupling and nozzle SR-ST inside cabin. Hoses with quick change couplings at the device.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PH-CLEANTEC GMBH

Germany

All media contacted parts are resistant against acid and demineralised water, media must be compatible with V2A stainless steel, version 1.4301. Mobile. Parts cleaning collector with sturdy drip-off grid, 80 kg load capacity, 30l. Water recycling via special sedimentation system with filter monitoring. 60 l water tank, 5 l cleaning agent reservoir, stepless adjustable pressure, metering device for cleaning agent, water shortage control, overheat fuse. Volume 1,8 l /m. 10 KW, 16A. 5 m hose with large pistol, hand screw coupling and lance ESR-LA 600, 2 m hose with small pistol, quick change coupling and nozzle ESR-ST. Hoses with quick change couplings at the device.

Request for a quote

PH-CLEANTEC GMBH

Germany

Mobile. Parts cleaning collector with sturdy drip-off grid, 80 kg load capacity, 30l. Water recycling via special sedimentation system with filter monitoring. 60 l water tank, 5 l cleaning agent reservoir, stepless adjustable pressure, metering device for cleaning agent, water shortage control, overheat fuse. Volume 2,8 l /m. 15KW, 32A. 5 m hose with large pistol, hand screw coupling and lance SR-LA 600, 2 m hose with small pistol, quick change coupling and nozzle SR-ST. Hoses with quick change couplings at the device.

Request for a quote

PH-CLEANTEC GMBH

Germany

Mobile. Parts cleaning collector with sturdy drip-off grid, 80 kg load capacity, 30l. Water recycling via special sedimentation system with filter monitoring. 60 l water tank, 5 l cleaning agent reservoir, stepless adjustable pressure, metering device for cleaning agent, water shortage control, overheat fuse. Volume 1,8 l /m. 10 KW, 16A. 5 m hose with large pistol, hand screw coupling and lance SR-LA 600, 2 m hose with small pistol, quick change coupling and nozzle SR-ST. Hoses with quick change couplings at the device.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

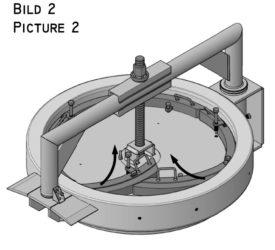

Segment Quick Closure, type VSV special equipment for horizontal filters and separators FEATURES short maintanance time for cartridge replacement reduced personnel deployment fast opening and closing procedure safety device for decommissioning and commissioning segment closure design combined with davit or lifting device suitable for extreme weather conditions (ice, sand …) additional equipment: weather protection hood (rain cap) SAFETY DEVICE Our safety device forces a so-called forced ventilation to open the device. The lid can only be opened in the following step if the appliance is depressurised. When the apparatus is in operation and pressurized, the safety device ensures that the shutter can not be opened during operation. DELIVERY We reserve the right to equip only vessels designed by us with our quick closure (Q/C). Our Q/C can not be purchased as a purchased part. Accessories, Special Equipment DAVIT (SWIVEL AID)

Request for a quote

AROTCO

Germany

Licorice root enters crushing machines after cleaning and drying by modern machines. The crushed roots are transferred to all-steel extractors and boiled in a specific process by steam to extract the root. The root extract is transferred to all-steel tanks and the impurities are completely separated from the extract in this level, and then the extract without impurities is passed through special filters again for more safety. Finally, in order to concentrate, the dilute extract enters the falling film vacuum evaporator and the thin film evaporator. Our trading company offers licorice liquid extract with concentrations of 40 to 70%.

Request for a quote

WESTFALEN CARE GMBH

Germany

"Special features: ›Innovative 1-layer filter material instead of the standard 3-layer material with a significantly lighter weight of ≤ 45 [g / m2] ›Production site: Lichtenau in North Rhine-Westphalia ›Use of 100% renewable energies (RE) in the production process Description: Innovative 1-layer filter material instead of the commercially available 3-layer material with a significantly lighter weight of ≤ 45 [g / m2], Production site: Lichtenau in North Rhine-Westphalia, Use of 100% renewable energies (RE) in the production process. Main features: Particularly suitable due to its pleasantly soft comfort in the common folding design, High quality and skin-friendly material, completely hydrophobic, does not allow liquids to pass through and enables easier breathing, Anatomically adaptable shape with nose clip and elastic ear straps (not latex-free). Instructions for use: For private use only. Not a medical device or personal protective equipment.

Request for a quote

AEROFIL INTERNATIONAL GMBH

Germany

AERO CELL GT are deep pleated box style filters with medium efficiencies. It is made from micro fine fiberglass paper media and comes with metal frames. Filters are available in M6 and F8 efficiencies. We offer this is a double header construction. These filters are specially designed to operate in harsh conditions such as Gas Turbines and Air

Request for a quoteResults for

Special filters - Import exportNumber of results

25 ProductsCountries

Company type