- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special filters

Results for

Special filters - Import export

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Special solutions for extraction from one or more sources of emission, designed and manufactured in accordance with special customer requirements. Special filters Special filter systems are designed for extraction from one or more sources of emission. We design and manufacture them in accordance with the special requirements of our customers. These filters are usually based on our own proven designs, which we then specially modify. Special applications or special solutions implemented: Special versions:

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

The requirements for reliable filter technology are extremely diverse. KOPP is responding to this with a comprehensive range of reliable filter devices. Special designs are also possible. Filter devices Wide range of products for every need Drinking water is supplied by the waterworks clean and without contamination. However, on its way through the extensive network of pipes, water can pick up dirt particles, which cause unpleasant malfunctions and operational interruptions and thus cause costly failures, for example in machines, pumps, valves or household appliances. By installing a filter, you ensure that disruptive particles are retained. This way you avoid operational disruptions and expensive repairs. The requirements for reliable filter technology are extremely diverse. KOPP is responding to this with a comprehensive range of reliable filter devices. Special designs are also possible. Individual solutions for every need – that’s KOPP. Also in the area of filter technology.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

For forced drying. Drying rooms Drying rooms offer the possibility to make the drying process faster and more comprehensible through forced drying. Depending on the paint systems, the temperature and humidity of the air can be adapted to suit the special requirements. In the high-gloss field in particular, special filters ensure the demanded degree of purity. Depending on the size and the specific task, Rippert also offers its drying rooms with heat recovery.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

With high-quality filter tubes and PTFE diaphragms. Paint dust filters Wet painting also results in overspray. Overspray is the solid portion of the paint that is not taken up by the workpiece. According to the purpose of use, the overspray is moist and sticky immediately after release. It is captured by the exhaust air stream in the spray booth and fed to a filter. This can be, for example, a baffle plate filter, paper filter, fleece filter, glass fibre filter or also combinations of these. The adhesive effect causes the paint particles to adhere to the contact surfaces of the respective filter medium, as a result of which a good degree of separation is achieved. However, all these filters are storage filters, i.e. the filters clog up more and more during operation and cannot be regenerated. A filter exchange becomes necessary if the exhaust air rate of the spray booth falls below the minimum. This can be very time-consuming under certain circumstances and the work process must be interrupted in order to do it. To make things worse, not only must the filtered and bound paint residues be disposed of, but also the actual filter materials. Such tooling times are not justifiable for automatic, continuous or multi-layer painting processes. Continuous procedures such as automatically cleaned filters are likewise required for this. The humidity and the adhesiveness of the particles to be filtered are thereby the problem. In order to solve this problem, the paint particles should be relieved of their adhesive capability as far as possible whilst still inside the paint booth. Our patented ‘RTS-Rotation’ system is outstandingly well suited for this. The system is comprised of slowly rotating brush rollers, which take up the adhesive paint particles on the surface of the bristles and allow them to dry there. The bristles are automatically regenerated at pre-specified time intervals by combing devices that swing in at the rear of the brush rollers. The dislodged paint residues can then be removed and disposed of either manually during work breaks or automatically during operation. The degree of separation of this system is, however, insufficient to satisfy the environmental protection requirements concerning residual dust content in the exhaust air. A further filter stage is necessary for that. It must be assumed that the paint particles arriving here are to a certain extent still damp and sticky. For this we use special paint dust filters with high-quality filter tubes with PTFE diaphragms. If necessary, precoating agents (auxiliary dust) are used in order to neutralise the adhesive capability of the particles and to keep the dust layer on the filter elements permeable to air. The precoating agent is injected into the raw air pipe by means of special dosing units. The filter tubes are cleaned by means of compressed air impulse cleaning. The use of this technology requires special know-how. We have had the appropriate experience for almost ten years. The implemented plants have capacities ranging from 5,000 to 90,000 m³ /h. Because of the large number of different paint systems, individual experiments are usually necessary in our pilot plant in order to find the correct solution for the individual case.

Request for a quote

STRONG MAGNETS GMBH

Germany

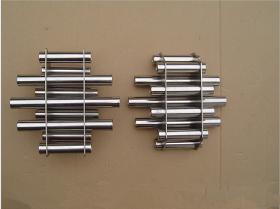

Scope of application Magnetic filter rod (magnetic rod) is mainly used to remove ferromagnetic impurities in powder, granular and liquid or slurry. It is widely used in ceramics, power, mining, plastics, chemical industry, rubber, pharmaceuticals, food, environmental protection, pigments, dyes, electronics, metallurgy and other industries. Working Principle The magnetic rod is made of high quality stainless steel pipe and high B value rare earth alloy NdFeB, and is made by special manufacturing method. The magnetic filter can be assembled on a fixed frame to form a magnetic filter. When the material containing iron passes through, it is attracted by the magnetic rod, and the material containing iron is firmly adsorbed on the wall of the magnetic rod. To ensure the integrity of equipment and product safety. Product features energyfree, pollutionfree, can be installed in any position on the production line with material contact, saving space, easy installation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WESTFALEN CARE GMBH

Germany

"Special features: ›Innovative 1-layer filter material instead of the standard 3-layer material with a significantly lighter weight of ≤ 45 [g / m2] ›Production site: Lichtenau in North Rhine-Westphalia ›Use of 100% renewable energies (RE) in the production process Description: Innovative 1-layer filter material instead of the commercially available 3-layer material with a significantly lighter weight of ≤ 45 [g / m2], Production site: Lichtenau in North Rhine-Westphalia, Use of 100% renewable energies (RE) in the production process. Main features: Particularly suitable due to its pleasantly soft comfort in the common folding design, High quality and skin-friendly material, completely hydrophobic, does not allow liquids to pass through and enables easier breathing, Anatomically adaptable shape with nose clip and elastic ear straps (not latex-free). Instructions for use: For private use only. Not a medical device or personal protective equipment.

Request for a quoteResults for

Special filters - Import exportNumber of results

7 ProductsCompany type