- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- single row bearing

Results for

Single row bearing - Import export

KFB CLARFELD GERMANY GMBH

Germany

Single row cylinder roller bearings with retainer are available as loose bearings, support bearings and fixed bearings. In the range of single row cylinder roller bearings are the model types N, NJ, NU and NUP, whereas the model series NN includes the double row cylinder roller bearings.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Single row deep groove ball bearings (Typ: 6000/6200/6300) Double row deep groove ball bearings (Typ: 4200) RDEEP GROOVE BALL BEARING Single row deep groove ball bearings (Type: 6000/6200/6300) Double row deep groove ball bearings (Type 4200) Deep groove ball bearings are wide ranging, non-separable bearings with solid outer rings, inner rings and bearing housings. These simply built products, steadfast in operation and maintenance friendly, are available as single and double row as well as sealed and open. In technical production, open bearings can have a recess on the outer ring for seals or cover rings. Due to their low moment of friction, deep groove ball bearings are suited to high speeds. Single and double row ball bearings are the most utilised anti-friction bearing. They are simple in construction, non-separable, suited to high speeds and unsusceptible in operation and maintenance. Narrow lubrication between running grooves and balls.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

require high precision, large rated moving load, and high maximum rotation speed. By adopting the new technology of material processing, KFB has successfully manufactured bearings of long service life that are highly fatigue resistant and impact resistant. The types of bearings made by KFB for the metallurgical roller mills are: split bearings; unit rollers; support roller bearings; single row, double row, three row, four row cylindrical roller bearings, fully-loaded cylindrical roller bearings, spherical roller bearings. The use of split bearings appreciably facilitates assembly and repair operations compared to the use of nonsplit (conventional) bearings. It does away with the need for the disassembly and subsequent reassembly of intermediate parts and mechanisms, which is required when replacing conventional bearings. It also reduces costs and production losses. If provided with efficient cooling, reliable lubrication and proper sealing, split-bearing components can be used...

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

double row cylindrical roller bearings ball bearings spherical roller bearings cylindrical roller bearings specified by UIC double row cylindrical roller bearings standardized by UIC single and double row tapered roller bearings standardized by UIC axle box transmission traction motors B-asymmetrical rollers C-symmetrical rollers R-bearings without inner rings M-machined brass cage, roller centered MA-machined brass cage, outer ring centered TN-injection moulded cage of glass fibre according with ISO 281:2007 W33-annular groove and three lubrication holes P6-according with ISO tolerance class 6 No code-standard C3-greater than standard C4-greater than C3 K-tapered bore ratio 1:12 No code-cylindrical

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

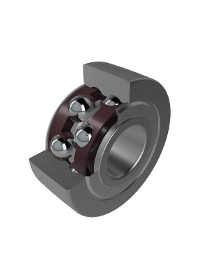

Our KIS track rollers are available as self-retaining, single or double row ball bearings with particularly strong outer rings. In addition to high radial forces, they also absorb axial forces in both directions. Track rollers are characterised by their robust construction featuring particularly thick-walled outer rings with a crowned outer surface (alternatively with a cylindrical outer surface or outer profile). They are designed to carry high radial loads and also tolerate axial loads that can arise due to minor misalignments, skewing or short-term start-up shocks. The assembly is constructed with a fixed inner ring mounted on axles. In this case, the track rollers are not installed in a housing bore, but are supported on a flat raceway (mating track). To ensure a reliable seal, the track rollers are fitted with a lip seal or cover discs on both sides. This prevents the ingress of dirt, dust and other contaminants while maintaining lubrication inside the bearing.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

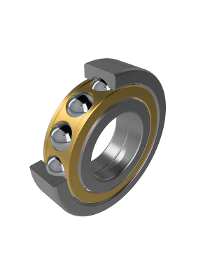

We design our angular contact ball bearings especially for bearing arrangements that have to support combined loads such as radial and axial forces acting simultaneously. As the name suggests, in angular contact ball bearings the forces are transmitted from one raceway to the other at a specific contact angle, oblique to the radial plane. As the nominal pressure angle increases, so does the axial load carrying capacity. Our KIS range includes single-row angular contact ball bearings as well as bearings arranged in pairs. Depending on the application requirement, which for example has a small installation space and requires a rigid bearing arrangement, a double-row design may also be suitable. We are happy to work with you to find the perfect KIS solution for your application.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

close tolerances and longitudinally welded carrying roller tubes made of S235JR steel in accordance with DIN 2458; deep drawn steel bearing retainers with calibrated bearing seats pressed in from the side and circularly welded, material thickness min. s = 2.00 mm; RAL 3000 red powder coated sheath, coating thickness min. 60 U; 20 mm Ø round steel in accordance with ISO h9; single row radial steel ball bearings in accordance with DIN625 type 6204 with suitable grease filling and cover plates on both sides made of sheet steel C3 bearing clearance. The calculated service life of the ball bearings, assuming belt speed 2m/sec. delivery capacity 200 t/he bulk weight 0.75 t/m³ temperature range 0° C 50° C is 30,000 hours. Steel circlip in accordance with DIN 471 Sealing using double labyrinth seal, incl. suitable grease filling, galvanized, sheet steel sealing cap and plastic rain cap

Request for a quoteResults for

Single row bearing - Import exportNumber of results

8 ProductsCountries

Company type