- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- duplex steels

Results for

Duplex steels - Import export

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Suction capacity 6,000 to 11,00 m³/h The NASH 2BQ1 590 has a unique performance range. It combines a high gas flow rate (6,000 to 11,000 m³/h) with a discharge pressure range of up to 3.75 bar abs. The standard 2BQ compressor model is equipped with a duplex steel shaft, ductile iron end shields, a massive stainless steel housing and o-rings to seal housing components. Higher quality materials are available on demand by using the modular 2BE3/4 design. The NASH 2BQ1 is certified for ATEX.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

100 - 1800 CFM / 170 to 3,050 m³/h The GARO line of liquid ring compressors expands the capacity and pressure ranges of the Nash line to meet the ever growing requirements of our customers. Found primarily in petroleum refineries and chemical plants, these rugged and reliable compressors handle highly toxic, explosive and corrosive gases in applications such as flare-gas, chlorine and Vinyl Chlorine Monomer (VCM) recovery. The GARO line, available in single and two-stage designs, comes in: cast iron, stainless steel, carbon steel, spheroidal cast iron, 316 stainless steel, duplex stainless steel, and Hastelloy or Titanium on select models. Together with other NASH liquid ring compressors, including the HP-9, the 14 GARO models form the NASH core compressor product line, which provides compression greater than 200 psig (15 Bar abs). Low pressure compressors are available to 30 psig (3 Bar abs), and 20,000 CFM (34,000 m³/hr). As a result, NASH offers the widest pressure and capacity ranges of liquid ring compressors available worldwide.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

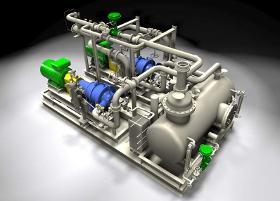

All components pass a quality inspection before being used. Many different methods and procedures are used here (e.g. PMI 0 positive material inspection, crack detection). Our scope of machining reaches from chipping/metal cutting to sandblasting (using granule materials) to welding, assembling and painting. We handle many different metallic and nonmetallic materials as steel, stainless steel, duplex materials, titanium, plastic material We give a big importance to welding: Nash employees are certified according to ASME 9 and therefore qualified to manufacture pressure vessels and piping according to Pressure Equipment Directive (DIN EN 3834) and ASME Standards (31.3). Our systems are painted according to customer specification. We work with all wet paints and 2K paints. Anti-corrosion-coatings up to category C5M are possible. Of course, we meet all the other specifications, e.g. regarding coating thickness, as well. The electrical engineering is also done in the Nash location, from design to cabling. After the completion, the system undergoes a pressure test. Furthermore there is an option to do a complete function test to verify the performance data. Nash is certified according to ISO 9001 and ISO 14001.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

From the first planning to shipment, every project is accompanied by one constant contact person. Depending on industry, process and specification, the best material (steel, stainless steel, duplex materials, titanium, plastic material) is chosen. There is a big importance to consider and meet the different standards and rules. Whether its DIN, ISO, ATEX, GOST ASME or PED (pressure equipment directive) - Nash engineers know all these general frameworks and restrictions. Our team of engineers finds the best solution to realize the customer's requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Duplex steels - Import exportNumber of results

4 ProductsCountries

Company type

Category