- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- duplex steels

Results for

Duplex steels - Import export

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

Stainless steel hollow float balls - with duplex mounting made of AISI 316 - V4A in diameters from 90 - 220mm especially in combination with the float valve series stainless steel Diamond the float for highest demands on material, quality and workmanship. The duplex mounting is innovative and allows the attachment in 2 variants. On external thread and on float rods.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

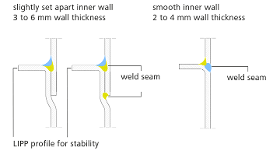

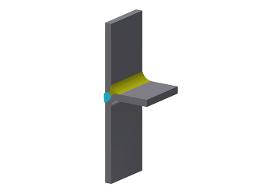

Special features of the Lipp welding technology are the automated on site construction of above the ground cylindrical tanks made of various grades of duplex steel, stainless steel and black steel. Moreover, the technology also incorporates the post treatment of the weld and a visualized welding monitoring and the technical documentation of the process. Due to the flexible and mobile concept of the equipment, the installation can either be done on greenfield construction sites but also inside buildings or in places with limited access and working space.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

TECHNOLOGICAL INNOVATION OPENING UP NEW MARKETS The new automated Lipp welding process will again shake up tank construction market just as the well established Lipp double fold system did decades ago. It is a perfect combination of the long experience in metal forming and state of the art welding technology. KEY BENEFITS OF THE LIPP WELDING TECHNOLOGY Automated welding proces, on site Visual weld monitoring and technical documentation Reinforcement ribs for enhanced structural stability and reduced material costs High quality and repeatability Fast installation Choice of different material grades and types CERTIFICATES SPECIFICATIONS OF THE LIPP WELDING TECHNOLOGY BLACK STEEL SPECIFICATIONS OF THE LIPP WELDING TECHNOLOGY STAINLESS STEEL Beside black steel, various grades of stainless steel and duplex steel can be auto welded. In addition to the new potential markets and applications, the Lipp automated welding technology will increase the competitiveness

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

KB Schmiedetechnik GmbH is a drop forge in West Germany, located between the historic “blade & metal region” Solingen-Remscheid-Wuppertal and the “Borussia soccer city” Dortmund, specialized in small series production of safety-relevant closed die forgings from 200g to 130Kg unit weight of all steel grades and alloys according to following certifications and standards: pressure equipment: valves, boiler systems, piping PED 97/23/EG, AD 2000-W0, ASME/ASTM, CNIM, Alstom, MHPS nuclear power/ atomic energy and plant construction KTA3201.1, KTA1401, AVS D 100/50, Siemens, EDF/Areva/RCC-M naval architecture/ shipbuilding and offshore/ ocean engineering, certified by •American Bureau of Shipping (ABS) •Bureau Veritas (BV) •Det Norske Veritas (DNV) •Lloyds Register (LR) •Nippon KaijiKyōkai (ClassNK) Examples: components and equipment like brackets, holders, chain links, hoists, lifting hooks, fasteners, pressure-bearing parts like valve bodies, pipe connections, and more.

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

Drop-forgings of carbon and alloyed steel, nickel, duplex, titanium and superalloys like Monel® or Hastelloy®, Inconel®, Incoloy® for pressurized components like forged valves or valve parts like bodies and yokes or bonnets, flanges for boiler systems, fittings for piping, non-corroding parts for shipbuilding, marine technology, slings and lifting gear, hooks, eyebolts, nuts, chain links, military vehicles, transportation and defense. Every nut, bolt, and screw - forgings for harsh environments: forged valve bodies, bonnets, yokes and flanges, pipe connections, pressure applications like boiler parts, hoists, chain links, eyebolts, hydraulic components, corrosion and acid-resistant parts for chemical and fertilizer industries, as well as shipbuilding and drill equipment. Pressure equipment and nuclear power (valves, boilers, piping): PED 2014/68/EU, AD 2000-W0, ASME/ASTM, KTA, RCC-M Shipbuilding and maritime industry ABS, BV Marine & Offshore, DNV, LR Shipping, ClassNK

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

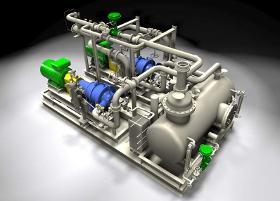

Suction capacity 6,000 to 11,00 m³/h The NASH 2BQ1 590 has a unique performance range. It combines a high gas flow rate (6,000 to 11,000 m³/h) with a discharge pressure range of up to 3.75 bar abs. The standard 2BQ compressor model is equipped with a duplex steel shaft, ductile iron end shields, a massive stainless steel housing and o-rings to seal housing components. Higher quality materials are available on demand by using the modular 2BE3/4 design. The NASH 2BQ1 is certified for ATEX.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

100 - 1800 CFM / 170 to 3,050 m³/h The GARO line of liquid ring compressors expands the capacity and pressure ranges of the Nash line to meet the ever growing requirements of our customers. Found primarily in petroleum refineries and chemical plants, these rugged and reliable compressors handle highly toxic, explosive and corrosive gases in applications such as flare-gas, chlorine and Vinyl Chlorine Monomer (VCM) recovery. The GARO line, available in single and two-stage designs, comes in: cast iron, stainless steel, carbon steel, spheroidal cast iron, 316 stainless steel, duplex stainless steel, and Hastelloy or Titanium on select models. Together with other NASH liquid ring compressors, including the HP-9, the 14 GARO models form the NASH core compressor product line, which provides compression greater than 200 psig (15 Bar abs). Low pressure compressors are available to 30 psig (3 Bar abs), and 20,000 CFM (34,000 m³/hr). As a result, NASH offers the widest pressure and capacity ranges of liquid ring compressors available worldwide.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

All components pass a quality inspection before being used. Many different methods and procedures are used here (e.g. PMI 0 positive material inspection, crack detection). Our scope of machining reaches from chipping/metal cutting to sandblasting (using granule materials) to welding, assembling and painting. We handle many different metallic and nonmetallic materials as steel, stainless steel, duplex materials, titanium, plastic material We give a big importance to welding: Nash employees are certified according to ASME 9 and therefore qualified to manufacture pressure vessels and piping according to Pressure Equipment Directive (DIN EN 3834) and ASME Standards (31.3). Our systems are painted according to customer specification. We work with all wet paints and 2K paints. Anti-corrosion-coatings up to category C5M are possible. Of course, we meet all the other specifications, e.g. regarding coating thickness, as well. The electrical engineering is also done in the Nash location, from design to cabling. After the completion, the system undergoes a pressure test. Furthermore there is an option to do a complete function test to verify the performance data. Nash is certified according to ISO 9001 and ISO 14001.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

From the first planning to shipment, every project is accompanied by one constant contact person. Depending on industry, process and specification, the best material (steel, stainless steel, duplex materials, titanium, plastic material) is chosen. There is a big importance to consider and meet the different standards and rules. Whether its DIN, ISO, ATEX, GOST ASME or PED (pressure equipment directive) - Nash engineers know all these general frameworks and restrictions. Our team of engineers finds the best solution to realize the customer's requirements.

Request for a quote

ASSFALG GMBH

Germany

The automatic recess chamfering machine ASO 910 is for welded seam treatment of, for example, duplex steel. The recess chamfering or resetting of cladding is mastered excellently by the edge chamfering machine. The attachment of chamfers on the top edge of the workpiece is possible up to 65mm. Thanks to the gradual angle adjustment from 90° - 75°, clean transitions are created between two workpieces with different thicknesses. The machine is very durable and shows its’ strength in every material through their sturdy construction. Extremely high tool service life can be achieved with the low-speed chamfering. Sheet thickness started at 8mm can be processed. The front, top and/or bottom side can be processed in one step through a special shape chamfer. Cavities in the front can be chamfered using the disc groove cutter. Advantages: Easy to adjust to material thickness, chamfer angle and working height Cutter head can be set in Z and X-axis No thermal change to the material

Request for a quoteResults for

Duplex steels - Import exportNumber of results

11 ProductsCountries

Company type