- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rubber belts

Results for

Rubber belts - Import export

CARL FRIEDRICH USBECK KG

Germany

cam type closure*cork lined jaws*capacity Ø 60 –170 mm*rod Ø 10 mm

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper CROMA high-performance flat belts are made of fully synthetic polyamide foils, with a one-sided or two-sided adhesion coating of chrome-split leather. Fitted with a polyamide reinforcement. With a one-sided or two-sided coating of chrome-split leather, highly resistant to abrasion and wear. Chrome-split leather is used exclusively as a friction coating on power transmission belts as an alternative to nitrile-butadiene rubber (NBR). CROMA belts with a coating of chrome-split leather are perfect for power transmission applications where the rollers are considerably contaminated by oil and dirt. In view of its slightly porous surface, chrome-split leather is air and humidity permeable and absorbs moisture; thus, it retains friction. However, the coefficient of friction of leather is lower than that for nitrile-butadiene rubber and steadily decreases during operation.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

KEIPER has an extensive range of flat belts, including high-performance flat belts, power transmission belts, folder-gluer belts, machine belts, tangential belts and conveying belts. For the perfect power transmission, conveying or control solution in any industrial sector. Keiper flat belts are designed to meet your specific requirements and applications, and, accordingly, they are made to size. Our flat belts are made of different traction layers and composite structures with different coatings such as nitrile-butadiene rubber, leather and surface structures. FLEXA With a polyamide or polyester reinforcement With a one-sided or two-sided coating of nitrile-butadiene rubber, highly resistant to abrasion and wear Different surface structures CROMA With a polyamide reinforcement With a one-sided or two-sided coating of chrome-split leather, highly resistant to abrasion and wear Butt leather belts Made of pure prestretched butt leather Rubber-and-fabric belts

Request for a quote

FORBO SIEGLING GMBH

Germany

Conveying heavy-duty products presents huge challenges to the conveyor belts used. With four product series, the Siegling Transtex range offers top performance in the most diverse of applications. Global logistics service providers have been using Siegling Transtex successfully for years when typical conveyor belts for light-materials handling reached their limits. In wind and extreme weather conditions, high temperatures and unusual mechanical stress, steel and rubber conveyor belts were the first choice for a long time. Siegling Transtex is the ideal alternative for many applications – with all the benefits of fabric-based conveyor belts: -easy to make endless -low energy consumption -simple conveyor design -low maintenance and repair costs

Request for a quote

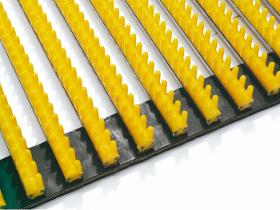

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

The row of fingers is cast on a steel rod and then riveted with other rods on a belt of rubber.

Request for a quote

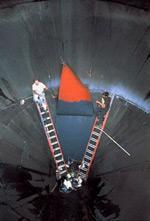

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Finishing on a sanfor line provides the fabric with a more stable structure, a silklike shine, a smoother touch and minimum residual shrinkage. The rubberbelt compacting line is made for the sanforisation and compacting of woven fabric and some kinds of knitted fabric, in combination with a felt belt calender the fabric gets on these lines additionally a special touch. The benefits are among others optimum residual shrinkage due to the hightech drive concept, stabilisation of the fabric structure, silklike shine, soft fabric touch, absolutely constant shrinkage due to a new automatic shrinkage control system available as option, production speeds up to 100 m/min are possible, extended service life of the rubber belt due to the larger diameter of the compacting rollers and an optimised rubber belt cooling system, integrated menudriven rubber belt grinding process, minimisation of vibrations, all bearings arranged outside of the wet area and therefore no corrosion.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Compacting is the last finishing process after relaxation or drying and has thus decisive importance for the residual shrinking, the hand and the aspect and the shine of the fabric before cutting and makeup. The BRÜCKNER compacting calender is characterized by an extremely short fabric path, an optimum traction control and a sophisticated drive technology allowing high production speeds with consistent fabric quality. Depending on the fabric type and the quality requirements, BRÜCKNER can offer the following compacting solutions two felt belt compactors arranged one behind the other, rubber belt shrinking unit according to the Sanfor principle, rubber belt shrinking unit with downstream arranged felt belt compacting calender. In addition, the following units can be integrated into the compacting line equalizing frame for the overspreading and width control, straightener, steamer unit, edge cutter (knife or scissor type).

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

mechanical belt connectors for use with most PVC, rubber and steel elevator belts, e.g. Supergrip belt connectors Easy to install system with 50 mm segment widths Four versions for up to 1,250 kN/m without limiting belt strength Max. temperature 80ºC, lock nut with nylon insert (standard) Type BC belt connector for steel mesh belts Four versions for up to 2,500 kN/m belt tensile force Maximum stability using high load bolts with self locking nuts Top quality construction in steel and extruded aluminium

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Metal connectors with self tapping screws are provided for the fast connection of rubber belts using a cordless screwdriver. FTK connectors are also available for round balers and in a special version for grape harvesting machines. Our steel connectors come in galvanised steel or non magnetic stainless steel. FTK connectors can be installed just using a cordless screwdriver because the screws are self tapping. No hole drilling is needed. FTK connectors are available with screws and connecting cables in lengths up to 3,000 mm, depending on belt width. A variety of connecting rods, lock washers and screws is also available for the initial installation of FTK connectors or as spare parts, plus various cordless screwdrivers, a pneumatic screwdriver, brace, PZ 2 cross head bits and a magnetic bit holder.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

We stock skirting rubber, belt cleaning rubber seals, nap rubber seals. Sheet rubber with or without contact layer available in different specifications and dimensions.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Exceptional working characteristics Suitable for the repair of conveyor belts, rubber coatings and linings, as well as for joint seals Two component polyurethane cartridge system Short working and application times Fast, clean and flexible Dry to the touch after 2 minutes Can be ground back and finished after 30 minutes No volatile components Break , impact and abrasion resistant Max. hardness of 60 Shore A Manual application or using a spray system

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK side guide rubber is used for particularly fine grained and dusty conveyed goods to seal the material guides of the conveyor belt system. FTK side guide rubber protects the conveyor belt and is mounted along the long sides of the conveyor belt. FTK lateral guide rubber is very flexible and adapts variably to the structures of the conveyor belt surfaces. FTK side guide rubber is available in red 40 45 ° Shore, black 60 65 Shore and in 50 ° Shore.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

high level of dust sealing at the location where material is fed onto the belt conveyor minimal wastage a buffer for the material falling onto the belt conveyor reduced cleaning costs increased conveyor belt service life increased operational safety simple assembly no welding necessary exchange of the adapter piece for existing conveyor rollers Measurements of the impact bars approx. 1240 x 100 x 75 (L x W x H) The impact bars can be fitted using the enclosed screws optimal alignment of the skirting rubber on the conveyor belt

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanLine® Black 60 Applications: germanLine® Black 60 is mainly used when wear resistance has to be extremely high, i.e. when dealing with rough abrasive material and great heights of drop. germanLine® Black 60 shows excellent tear and tensile strengths. Available dimensions: Thickness: 5 / 8 / 10 / 12 / 15 / 20 mm Width: 1,500 / 2,000 mm Available length: 10 / 20 m Specifications: Colour: black Hardness: 60 ± 5 ° Shore A Tensile strength: ≥ 17 MPa Elongation at breaj: ≥ 400 % Abrasion: ≤ 130 mm³ at 10 N Downloads: Technical Data Sheet germanLine® Black 60 - English [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanLine® Beige 35 with CN Layer Applications: germanLine® Beige 35 with CN layer protects surfaces against wet wear and round grain as well as fine-grained, sharp or hard conveyor goods or slurries, such as wet grit. Our product is used in granulation drums, bunkers, skids or slides, pumps, skirts, chutes, silos etc. and serves as wear protection, shock absorber, sound insulation, protection against corrosion and caking. Available dimensions: Thickness: 4 / 6 / 8 / 10 / 12 / 15 / 20 mm Width: 1,500 / 2,000 mm Available length: 10 / 20 m Specifications: Colour: beige Density: 1.0 ± 0.03 g/cm³ Hardness: 35 ± 5 ° Shore A Tensile strength: ≥ 19 MPa Elongation at break: ≥ 650 % Abrasion: ≤ 95 mm³ at 5 N Breaking force: ≥ 50 N/mm Downloads: Technical Data Sheet germanLine® Beige 35 with CN Layer - Englisch [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanLine® Red 40 with CN Layer Applications: germanLine® Red 40 is suitable for extremely challenging conditions and has excellent wear resistance and sturdiness when it comes to sharp-edged grain. It can be used universally in dry and wet conditions - as pad, shock absorber and protection against caking. Available dimensions: Thickness: 4 / 6 / 8 / 10 / 12 / 15 / 20 mm Width: 1,500 / 2,000 mm Available length: 10 / 20 m Specifications: Colour: red Density: 1.08 ± 0.03 g/cm³ Hardness: 40 ± 5 ° Shore A Tensile strength: ≥ 17 MPa Elongation at break: ≥ 650 % Abrasion: ≤ 85 mm³ at 5 N Breaking force: ≥ 60 N/mm Downloads: Technical Data Sheet germanLine® Red 40 with CN Layer - English [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanLine® Black 60 mit CN-Schicht Applications: Standard quality with extremely high performance in wear resistance. For rough abrasive material and great heights of drop. germanLine® Black 60 shows excellent tear and tensile strengths. Available dimensions: Thickness: 4 / 6 / 8 / 10 / 12 / 15 / 20 mm Width: 1,500 / 2,000 mm Available length: 10 / 20 m Specifications: Colour: black Density: 1.10 ± 0.03 g/cm³ Hardness: 60 ± 5 ° Shore A Tensile strength: ≥ 20 MPa Elongation at break: ≥ 450 % Abrasion: ≤ 90 mm³ at 10 N Breaking force: ≥ 80 N/mm Downloads: Technical Data Sheet germanLine® Black 60 with CN Layer - English [PDF]

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GERMANBELT SYSTEMS GMBH

Germany

germanLine® Red 35 Applications: germanLine® Red 35 is particularly resistant to fine-grain, sharp-edged slurries such as wet gravel. It also is extremely resistant to wet wear and round-grain goods. germanLine® Red 35 wear protection rubber is an excellent sound absorber and reduces noise emission. It is mainly used as shock absorber and protection against corrosion and caking in bunkers, skids or slides, pumps, skirts, chutes, silos etc. Available dimensions: Thickness: 3 / 5 / 6 / 8 / 10 / 12 / 15 / 20 mm Width: 1,500 / 2,000 mm Available length: 10 / 20 m Specifications: Colour: red Hardness: 35 ± 5 ° Shore A Tensile strength: ≥ 19 MPa Elongation at break: ≥ 650 % Abrasion: ≤ 65 mm³ at 5 N Downloads: Technical Data Sheet germanLine® Red 35 - English [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanBond® 4kR CFC-free Applications: 2 component contact adhesive free of chlorinated hydrocarbon and aromates for cold bonding of conveyor rubber belts, rubber linings, friction laggings for pulleys and rollers as well as for the permanent-elastic and high-strength bonding of rubber, fabrics, leather, polyurethane and other materials. Specifications: Colour: black Hardener: germanBond® RE Cleaner/Diluent: germanBond® CLR Flash-off time: approx. 10 min (at 20°C) Application quantity: approx. 150 g/m² per coat Packing units: 0.65 kg - 4.0 kg - 24.0 kg - 170.0 kg Downloads: Safety Data Sheet germanBond® 4kR - English [PDF] Safety Data Sheet germanBond® RE - English [PDF] Application Instructions germanBond® 4kR - English [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanBond® 2kR Applications: 2 component contact adhesive non-inflammable for cold bonding of conveyor rubber belts, rubber linings, friction laggings for pulleys and rollers as well as for the permanent-elastic and high-strength bonding of rubber, fabrics, leather, polyurethane and other materials. Specifications: Colour: black Hardener: germanBond® RE Cleaner/Diluent: germanBond® CLT Flash-off time: approx. 10 min (at 20°C) Application quantity: approx. 250 g/m² per coat Packing units: 1.0 kg - 3.0 kg - 6.5 kg - 41.0 kg - 290.0kg Downloads: Safety Data Sheet germanBond® 2kR - English [PDF] Safety Data Sheet germanBond® RE - English [PDF] Application Instructions germanBond® 2kR - English [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanBond® REPAIR Applications: One component repair compound for the filling of damaged areas of rubber conveyor belts such as fabric conveyor belts or steel cord conveyor belts, rubber linings, drums/conveyor belt pulleys and cylinders. Specifications: Colour: black Final hardening after: approx. 24 h (at 20°C) Application quantity: approx. 1 kg/m² for 1 mm thickness Oil resistance: oil resistant according to DIN 53521 Shrinkage: 15 - 20 % Hardness Shore A: approx. 65 ° (after complete curing) Packing units: 1.0 kg Downloads: Safety Data Sheet germanBond® REPAIR - English [PDF] Application Instructions germanBond® REPAIR - English [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

Primer germanBond® MP Universal adhesion promoter for rubber to metal bonding. The product significantly improves adhesive strength and provides the conditioned steel surface with temporary protection against corrosion. Applications: such as for conveyor belt pulley rubber lining or conveyor belt pulley laggings of rubber or ceramics, container linings and wear protection linings. ... more

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

Adhesive germanBond® 4kR CFC-free Permanently elastic two-component contact adhesive for conveyor belt splices, conveyor belt repair and conveyor belt pulley lining, particularly for rubber/rubber, rubber/fabric, rubber/metal and fabric/fabric bonding. Applications: such as for cold bonding of rubber conveyor belts (splicing), wear protection linings, conveyor belt pulley and roller or idler laggings. ... more

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanBond® HS CFC-free Applications: For hot vulcanising rubber steel cord conveyor belts and fabric conveyor belts. Specifications: Colour: black Density: 0.75 g/ml Application: Brush Application quantity: approx. 150 - 200 g/m² per coat Storage requirements: dry, cool, in tightly closed buckets Shelf life: minimum of 6 months Packing units: 0.6 kg - 4.0 kg - 20.0 kg Downloads: Safety Data Sheet germanBond® HS - English [PDF] Application Instructions germanBond® HS - English [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

Heating solution germanBond® HS CFC-free Universally usable solution for hot vulcanization of splices at steel cord and fabric conveyor belts made of rubber. Our germanBond® HS heating solution contains a special elastomer compound whose adhesive system significantly improves the stickiness of the connecting parts and thus contributes to an optimal splicing strength. Applications: such as in the vulcanization of conveyor belt splices and conveyor belt repairs. ... more

Request for a quote

IIM AG MEASUREMENT + ENGINEERING

Germany

Device details: ■ Simplifies the cable sample arrangement for measuring under a microspcope or the VCPLab ■ Arranging with friction wheels, cogwheels and a durable rubber tooth belt ■ Easy and quick operation ■ Robust device made of aluminium, stainless steel and brass - no corrosion ■ Quick sample fixing of a cable sample due to a lever mechanism ■ Perfect for e.g. measuring the heat pressure test indentation according to 60811-508

Request for a quoteResults for

Rubber belts - Import exportNumber of results

27 ProductsCountries

Category

- Conveyor belts (9)

- Transmission belts (2)

- Rubber products (2)

- Boring - steels and metals (1)

- Clamp collars, plastic (1)

- Industrial analysis laboratory (1)

- Paper - Printing - Machines & Equipment (1)

- Plastic products for the farm-produce industry (1)

- Textiles - Machines & Equipment (1)

- Varnishing - steels and metals (1)