- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- profile processing

Results for

Profile processing - Import export

ALUMINIUMWERK UNNA AG

Germany

In the aluminium industry, the porthole extrusion process is the standard method for the production of extruded tubes and profiles. The process is limited to a number of aluminium alloys. However, most of the commercially available medium strength aluminium alloys such as EN AW-6060 or EN AW-6082 can be extruded by porthole extrusion.

Request for a quote

MICRO-EPSILON

Germany

scanCONTROL 30x2 laser scanners are powerful profile sensors in terms of size, accuracy and measuring rate. These laser scanners provide calibrated 2D profile data with up to approx. 8 million points per second. With a maximum profile frequency of 10 kHz, the scanners are designed for precise profile measurements in dynamic processes. The sensor matrix offers a resolution of 1,024 points with a point distance from 24 µm. This means that even small details can be detected reliably.

Request for a quote

MICRO-EPSILON

Germany

scanCONTROL 30x0 laser scanners are among the highest performing profile sensors in terms of their size, accuracy and measuring rate. They provide calibrated 2D profile data with up to approx. 10 million points per second. Their profile frequency of max. 10 kHz enables precise profile measurements in dynamic processes. The high-resolution sensor matrix offers a resolution of 2,048 points with an ultimate point distance of just 12 µm. This is how even the finest of details can be detected reliably.

Request for a quote

ALUMINIUMWERK UNNA AG

Germany

With the unique extrusion process, ALUnna has the capability to produce continuous lengths of extruded profiles. Unlike the conventional extrusion process, the continuous extrusion process does not use billets. Instead, raw material is fed into the process from a coil. This process is especially useful for the production of small extrusion profiles used as spacer bars in alloys EN AW-1050A / 1350A or EN AW-3103/3003. If necessary, there is an option to apply a draw pass to the spacer bar profile using an in-line Schumag continuous drawing machine in order to achieve the final dimension and the most demanding of tolerances.

Request for a quote

PRESSTA EISELE GMBH

Germany

4 axis CNC floor type vertical spindle machining centre. 4 axis (X, Y, Z, A) managed by CNC. By means of dedicated tools it’s suitable for working on 5 sides of profiles. Suitable for processing on ANY surfaces, generated by the rotation of the spindle axis (side by side at Y axes) on the positions within 180° (± 90°). The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The locking clamps slide on guide rail. The working table can be divided in two areas so to get two separate working stations. Using a disk cutter, it is possible to work on both sides at the end of the profile (end milling cycle). Milling operations can be performed with linear and circular interpolation of the axes X-Y-Z. The hinging length stop are pneumatically managed. The electric spindle is suitable for quick tool holder change. The tool magazine is mounted on the mobil upright. The tool change can be carried out into any position...

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

FOR STORING BIOMASS TO BE USED FOR ENERGY PRODUCTION OR ANIMAL FEED The LIPP System is based on a world wide unique and genuinely simple principle of tank production. Steel coils, machines and accessories are transported to the construction site, the production of the tank takes place on site – fast, efficiently and flexibly in height and diameter. In an automated, two stage process, a profile is formed from the steel strip which is joined in a second step – at the same time, the container rotates spirally. The tight and stability supporting connection of the steel band can be effected by the LIPP Double Seam as well as the LIPP Welding Technology. Compact and space saving High functional safety Reduced retention time in the digester Reduced energy losses during storage Low maintenance and durable Automatic feeding Storage losses as a result of oxidation are avoided

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The choice of the right profile sanding wheel for wood sanding must be determined based on the customer’s requirements. Our highly experienced engineers and application technicians would be pleased to advise you by phone or email, on a high quality and cost-effective type of profile sanding wheel of the FAPI-SW series for your process. The profile sanding wheels FAPI-SW are made of the same material used for flap grinding wheels. The significant difference lies in the highly elastic surface of the profile sanding wheel FAPI-SW. This is achieved with individual, disconnected slitted, abrasive cloth packages separated by a large distance to one another and fastened to the wheel hub.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

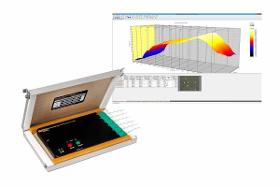

Process engineers worldwide use Datapaq temperature profiling and monitoring systems to optimize product quality, reduce waste, confirm compliance with industry standards and more. If our current offerings of specialty systems do not meet your requirements, the engineering team at Fluke Process Instruments will design a custom thermal profiling solution – complete with data logger, custom thermal barriers and our Insight™ Software. These bespoke systems enable through-process temperature profiles to be obtained in processes where trailing long thermocouples are not an option. Each thermal barrier is designed in close collaboration with the end-user, providing the optimum solution for every application. Data Loggers Fluke Process Instruments has a wide selection of data loggers ranging from the stainless steel cased Datapaq TP6 and the rugged Datapaq DP5 for high temperature heat treating to the Multipaq 21, Datapaq XL2

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

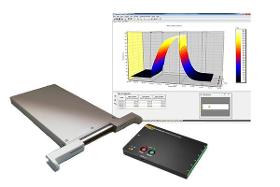

The Datapaq® Reflow Tracker® temperature profiling system travels through the process, enabling you to monitor wave and reflow soldering, as well as vapor phase, selective soldering and rework stations. Comprised of specifically designed thermocouples, data loggers, protective thermal barriers and Insight software, this system will help you optimize product quality, expedite process setup, increase yields and minimize the need for rework. For more details and specifications, download the Reflow Tracker System brochure. Insight Software for Reflow Tracker available in Basic, Standard and Professional versions Insight software is an easy-to-use analysis package designed by Datapaq to meet the needs of the electronics assembly industry. With a typical reflow soldering profile lasting only six minutes, users don't want to spend additional time analyzing the profile. Insight Software ensures that the user is presented with a detailed analysis immediately and it comes

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq Furnace Tracker Specialty Profiling Systems from Fluke Process Instruments features the Datapaq TP6 and Datapaq DP5 data loggers, hundreds of application specific thermal barriers, thermocouples and our intuitive Datapaq Insight™ Software to create a complete solution. These specialty systems enable through-process temperature profiles to be obtained in processes where long trailing thermocouples are not an option. Each thermal barrier is designed with a specific application in mind to provide the optimum solution for your process. If our current offerings of specialty systems do not meet your requirements, the engineering team at Fluke Process Instruments will design a custom thermal profiling solution. For more information, visit our customized profiling systems page. Data loggers The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Tunnel Kiln Tracker® temperature profiling systems are comprised of a data logger, a protective thermal barrier and Insight software. Using a Datapaq® system, you can obtain reliable and accurate in-process temperature profiling in tunnel kilns used to fire brick and roof tiles, tableware, sanitaryware, tile, refractory and more. For detailed information, download the Kiln Tracker System brochure. Kiln Tracker Insight Software Insight software takes the data gathered by the data logger, quickly interprets the information, and reports the analysis you need instantly. Wizards walk you through all the major software functions and simplify setups and analysis. Critical profile results are available on one easy-to-read screen, automatically informing you of any out-of-tolerance parameters. In addition, a software alarm warns you immediately of process issues, allowing you to take corrective action before product damage occurs. Features include

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq Furnace Tracker Temperature Uniformity Survey (TUS) System from Fluke Process Instruments features the choice of data logger (TP6 or XDL12), choice of thermal barrier (TB45 or TB46), thermocouples and our intuitive Temperature Uniformity Survey (TUS) Insight™ Software package to perform accurate in-process product thermal profiling while verifying conformity to all required specifications, including the AMS2750 standard. Data Loggers The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insight™ or Datapaq Insight Furnace Surveying software you can display information from the data logger in real time via the optional Radio Frequency (RF) system or via standard USB/Bluetooth connections. Available in 10 and 20 channel configurations and two case styles Water resistant (IP67 rated) Communication via USB or Bluetooth

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The smart solution: Fully-automatic defatting machine ASD 460 enables removal of fat layers from loins and cutlets in predefined strengths. Advantages Fully-automatic recognition of the fat strength using Weber camera technology, with programmable controlled movementalong longitudinal profile Continuous work process Sensor-controlled electronic spring for perfect pressure application Uniform fat layers Considerable minimisation of reworking (trimming) Back bacon instead of small trimming cuts Clearly improved product image for cooking after slicing Product-specific blade holders Combinable with pre-installed derinder Options: Special Weber transport rollers Product-specific blade holders Product-specific pressure devices for products withand without bones Fixed or adjustable guide plates for supply and output belts

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Datapaq Furnace Tracker temperature profilers are available for all kinds of thermal processes in the metals, steel, and glass industries. The systems based on the Datapaq DP5 data logger are designed for short and medium duration processes. The portfolio includes a comprehensive range of high-accuracy, industrial-strength DATA LOGGERS with six or 12 measurement channels, various THERMAL BARRIERS that protect the electronics from heavy-duty process conditions, the Datapaq Insight ANALYSIS SOFTWARE, and a selection of fast-response, high-temperature type K or N THERMOCOUPLES. Designed to ensure minimum running costs, DP5 loggers store up to 10 profile runs before download to a PC. The built-in harsh-environment radio transmitter provides real-time data from within the process, speeding up fault-finding and process optimizations. The loggers can be recharged from flat to usable in just five minutes. A full charge via high-speed USB takes only 90 minutes and can provide 20 profile runs.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The DATAPAQ temperature profiling systems are comprised of a data logger, a protective thermal barrier, software, and thermocouples. With a DATAPAQ Food Tracker, you can guarantee the quality and safety of your cooked meats, poultry, bakery products and ready-to-eat meals. DATAPAQ systems travel through the oven or freezer with the food product, making a complete record of product temperatures. You can monitor the product temperature of the entire cook/freeze cycle in either static or conveyorized ovens, as well as in steam cookers, deep fat fryers, and blast freezers. • Reliable and accurate HACCP temperature profiling systems for demanding food processing applications • Data logger (6 or 8 channels) with IP67 waterproofing rating • Stores up to eight runs before requiring data download • Comprehensive thermal barrier range • Powerful, yet easy-to-use Insight analysis software, including process lethality calculations • Various thermocouples to suit your range of products

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Tunnel Kiln Tracker temperature profiling systems are comprised of a data logger, a protective thermal barrier, software, and thermocouples. Using a DATAPAQ system, you can obtain reliable and accurate in-process temperature profiling in tunnel kilns used to fire brick and roof tiles, tableware, sanitaryware, tile, refractory and more. • Reliable profiling system for high temperatures and long process durations typical in the ceramics industry • Powerful and user-friendly DATAPAQ Insight analysis software • Highly accurate and programmable 10 or 20 channel data loggers storing up to 3.6 million data points • DATAPAQ TP3 data logger in a stainless-steel casing • Radio Telemetry option for real-time monitoring

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ Reflow Tracker temperature profiling systems Program includes — range of high-accuracy, industrial-strength, compact Datapaq DP5 data loggers — range of low-height thermal barriers — DATAPAQ Insight Reflow Tracker analysis software — selection of fast-response, high-temperature thermocouples for measuring SMD and PCB temperatures and process stability Applications include — WAVE SOLDERING – accessory: DATAPAQ wave pallet with up to 9 contact sensors and 3 preheat sensors; software functions include contact times and parallelism — SELECTIVE SOLDERING – accessory: DATAPAQ PA2200 selective soldering sensor for process stability measurement — VACUUM SOLDERING – optional data transmission via radio enables real-time data analysis — VAPOR PHASE SOLDERING – program includes a special range of sealed and lighter-weight thermal barriers — REWORK STATIONS – the DATAPAQ DP5 data logger with its USB and Bluetooth connectivity is ideal for high-speed, real-time monitoring

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ Furnace Tracker systems offer accurate and reliable in-process temperature profiling and surveying solutions for a wide variety of demanding high temperature heat treatment processes in the glass and metalls industries and in aluminum manufacturing (Annealing * Brazing * Homogenizing * Decorating * Tempering * Forming * Frit Sealing * Normalizing * Billet Reheating * Slab Reheating * Pressure and Vacuum Processes). TB4000 Series Thermal Barriers: Rugged 304 stainless steel construction Microporous insulation provides the best thermal protection of any known material Various heights available to meet limited clearances TB4900 Series Thermal Barriers Exceptional durability and thermal resistance Outstanding resistance to oxidation and distortion One way lid and base alignment avoids thermocouple damage DATAPAQ temperature profiling systems comprise high-accuracy industrial-strength data loggers, thermocouples, thermal barriers, and analysis software.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The DATAPAQ EasyTrack3 thermal profiling system is the third generation of the globally accepted EasyTrack brand successfully used by powder and paint coating applicators and suppliers. The DATAPAQ ET3 datalogger guarantees accurate temperature profiling and is designed with the easy two-button operation. Improved logger memory of x3 permits the profile detail your coating process demands (0.5 s sample interval = 2.5 hours run). A battery life is improved x2.5 over previous gen. Performing safely in up to 85 °C/185 °F, the plastic cool-touch case allows safe and comfortable handling even after the most demanding runs. Supplied with onboard calibration certificate, the logger provides complete traceability to comply with QA standards. • Improved logger design with more memory, battery life and onboard intelligence • New EasyTrack Insight Professional Software option with more operation, analysis & reporting power • New capabilities with multiple runs & SmartPaq PASS/FAIL indicator

Request for a quote

BEHA INNOVATION GMBH

Germany

Robust and accurate guiding clamps for different belt profiles and belt strips. The guide clamps are needed to fix the profiles or flat strips in exact alignment before the welding process.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The tubing specialist with unique precision and working speed for very thin, tension-elastic and pressure-sensitive materials. KL-BV is available in the equipment line Green and as KL-BV Gasket. The Metzner KL-BV cutting machine stands out for its precision, compact design, and the wide range of processing options such as silicone tubes, flexible profiles and gaskets. KL-BV GASKET With its particularly thin blades and precision feed, the KL-BV Gasket is ideal for cutting flat gaskets with a diameter of up to 12 mm.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK is your specialist in the production of cold-rolled profiles tailored to individual customer requirements. With a wide range of different technologies, we manufacture special profiles as customized functional elements up to complete assemblies. SCHOCK's roll forming technology operates economically and material-efficiently, offering significant advantages in product design: Unlimited range of shapes Highly precise functional dimensions Economical material utilization Energy-efficient manufacturing process SCHOCK special profiles are characterized by the highest precision and top-notch workmanship. With SCHOCK's roll forming technology, we produce profiles with extremely tight tolerances and excellent product properties. Thanks to creative tool solutions, we manufacture virtually burr-free profiles and process different materials with a tensile strength of up to 1000 MPa.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The Metzner CCM 2 circular cutting machine processes steel-reinforced profiles and sponge rubber materials with dry cutting (optionally with micro-knife moistening to cool the circular knife). The standard model comes with an integrated discharge conveyor (1300 mm length); range of application both in-line and off-line.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The VEN BRUSH system technology is based on high pressure at low speed. Special hold-down brushes with wide support brushes or narrow support brushes for processing profiled workpieces, ensure the required pressure. For the pretreatment of workpieces of varying shapes or extremely fluctuating sizes, maximum perfection and flexibility are provided by the motor-driven height adjustment of each individual unit as well as by the infinite rotational speed setting. The high-performance vacuum transport belt ensures reliable transport and holds both small as well as large format workpieces in place. A Molton roller is built in to ensure constant cleaning of the conveyor belt. Unit diversity results in a wide performance spectrum and generates a high economic effect. The basis version of VEN BRUSH allows a selection of 2 unit positions to up to 5 unit positions. To be prepared for possibly changing requirements in your production process, you can also select the next larger variant and equip the free unit position as required at a later date. System examples for possible operating widths from 600 to 3,500 and operating lengths from 2,000 to 5,500 mm. Depending on your production requirements, you can individually select from: Short change times and high operating comfort are possible thanks to the quick-exchange brush system using a push-in system together with a coupling. The optional infinite angle setting of the round brushes permits impeccable edge processing. The use of the structured brush unit is intended for special surface processing. This brush is used to structurise furniture parts, hardwood and softwood, flooring boards or to provide an antique look of up to 1 mm deep at a throughfeed speed of 10 m/min. Where required, the VEN BRUSH can be extended by a dust removal system with rotating blow nozzles and ionisation system. Following a brushing or sanding/grinding effect, this complementary function ensures optimum workpiece cleanliness to meet high requirements. As an individual solution, VEN BRUSH convinces as a station in a Venjakob machine line or when integrated in an existing machine line. As such, control system configuration takes all interfaces into account, through to higher ranking control and monitoring. The high-performance system technology can be easily operated directly using a control panel or a touch panel.

Request for a quote

IBG HYDROTECH GMBH

Germany

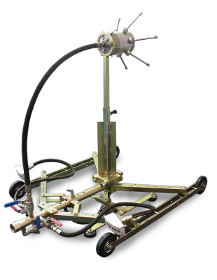

The GP 150 consists of a modular cage system with variable width and height for large profile channels (circular, egg, box profiles as well as profiles with dry weather channel). It is designed to enable the user to process a corresponding profile size with as few components and assembly work as possible. With only five plug-in connections and three screw connections, a maximum body size of DN 4,000 can be achieved.

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

With our fully automatic profile processing centers, we are able to carry out complex processing on profiles. — Elumatec SBZ-151 5-axis profile machining centrum with a machining length up to 9000 mm

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

With our saws and profile processing centers, we are able to precisely cut sheet metal and profiles on request. Elumatec DG244 double miter saw for lengths of up to 6000 mm, high-quality cutting of profiles made of aluminium, PVC and light metal alloys. Cutting profiles made of aluminium, PVC and non-ferrous metals with our SBZ-151 5-axis profile machining center from Elumatec.

Request for a quoteResults for

Profile processing - Import exportNumber of results

28 ProductsCountries

Category

- Temperature sensing devices (7)

- Infrared tubes (5)

- Mechanical engineering - custom work (2)

- Sensors (2)

- Pipes and tubes, aluminium (1)

- Aluminium alloys (1)

- Clamp collars, plastic (1)

- Meat processing machines (1)

- Rails and sliding frames (1)

- Sawing machine tools (1)

- Sections - non-ferrous metal (1)

- Tanks, metal (1)

- Transportation chains (1)

- Wheels, special (1)