- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing of wire

Results for

Processing of wire - Import export

ZOLLER & FRÖHLICH GMBH

Germany

The WPC is an integrated solution to produce wires for switch cabinets: it marks them and crimps the corresponding wire end ferrule. The WPC loads an EPLAN or other CAE file and produces all wires within this list step by step. Cross-sections from 0.5 mm² to 2.5 mm² are supported. For each item in this list, the wire is cut to length sequentially with the help of the multi feeder Z+F EVOFEED® , the corresponding labels are printed and the correct ferrule is crimped to the wire with the UNIC-GV universal crimping machine. The thermal transfer printer (THM-MMP) is suitable for all markers and labels of the MultiMark family as well as for continuous material, fabric and polyester labels, heat shrink tubing or PLC labels. The operation of the individual steps is carried out manually, which allows the operator to route and connect the wires for the complete job in the switch cabinet wire by wire. Due to the high level of automation it is not necessary to change wires and ferrules.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). We can wind onto any desired coil form using many different press-in ferrite and metallic cores. Multiple tap coils are also possible. Pins are automatically applied to the coil connections during the winding process, with wire drawing electrically controlled. Our winding machines handle single-chamber and multi-chamber coils with wire thicknesses from 0.045 to 0.71 millimetres.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electrical flange type immersion heaters The series of electrical Flange Type FHK-L provides a solution for the heating of liquids / molten salts or similar applications in process tanks or underground tanks. It can also be tank filling levels with very low heat, since only the lower horizontal portion is heated. The flange heater consists of a number of heating elements, which are built into the process flange. The electrical wiring is done in a robust electrical terminal box.

Request for a quote

DIETZ GMBH

Germany

Bent wire parts represent a separate part of our production range. Bent parts differ from springs such as extension springs, compression springs and wave springs in terms of how they are produced. This type of spring is not only processed with automated machinery, but also involves a considerable amount of special handling, which we perform using our range of state-of-the-art equipment. Precision production with our high-tech machinery: Our range of machinery with an in-house toolmaking workshop enables three-dimensional bent parts to be produced with a wide variety of forms and with specialised finishes applied to the ends. Our range of machining processes includes: Bevelling, embossing, thread cutting, thread rolling, turning and milling. For bent wire parts, both CNC bending and mould-based bending are possible as production solutions.We process wire thicknesses of 0.20 to 8.00mm.Tool-based: 0.50 to 8.00 mm. Coating of part surfaces: Oiling, Vibratory finishing, Galvanisation.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

State-of-the-art manufacturing techniques are used in our electrical workshop. The world-renowned and appreciated Z+F machines are used for wire processing. These assure a high quality standard of the final product and allow great time savings in the manufacturing process. Thereby we can offer our customers a good and fair price-performance ratio. Individual marking of wires is supported. UL approvals are also possible.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The AM 02.1 is an electropneumatic modular stripper-crimper for rapid and reliable processing of loose uninsulated Z+F ferrules. The stripper-crimper may be adapted by using the corresponding tools for ferrules of cross-sections from 0.25mm2 to 2.5 mm2 (AWG 24 – 14) and crimping lengths from 5mm to 12 mm. Specification For definition of the required tools the correct specification of the processed ferrules as well as the processed wires are needed. Options: Quadrocrimp-tool The stripper-crimper can be equipped with a quadrocrimp-tool which creates 4-side quadratic crimp.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The AM 04 is an electropneumatically driven, modular stripper crimper for the efficient processing of loose, insulated Z+F ferrules. The stripper crimper can be converted using appropriate set-up parts for wire end ferrules with cross sections from 4mm2 to 10 mm2 (AWG 12 - 8) and crimping lengths from 8mm to 18mm. Specification For defining required tools the correct specification of the processed ferrules as well as the processed wires are needed.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The AM 04 is an eletropneumatic modular stripper-crimper for rapid and reliable processing of loose insulated Z+F ferrules. The stripper-crimper may be adapted by using the corresponding tools for ferrules with cross-sections from 4mm2 to 10mm2 (AWG 12-8) and crimping lengths from 8mm to 18mm. Specification For exact definition of the requierd tools, the correct specification of the processed ferrules as well as the processed wires are needed. Option: Quadrocrimp-tool The stripper-crimper can be equipped with a quadrocrimp-tool, which creates a 4-side quadratic crimp.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The AM 04.1 is an electropneumatic, modular stripper-crimper for rapid and reliable processing of loose uninsulated Z+F ferrules. The stripper-crimper can be adapted by using the corresponding tools for ferrules of cross-sections from 4 up to 10 mm2 (AWG 12-8) and crimping lengths from 9mm to 18mm. Specification For definition of the required tools the correct specification of the processed ferrules as well as the processed wires are needed. Options: Quardrocrimp-tool The stripper-crimper can be equipped with a quadrocrimp-tool, which creates a 4-side quadratic crimp.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The UNIC-G is an electropneumatic stripper-crimper. This machine allows a quick and reliable processing of Z+F ferrules on reel in the range of 0.5mm2 up to 2.5 mm2 (AWG 20 – 14) without changing the tools. UNIC-G and UNIC-GS are now available with a fivefold infeed, which allows an even more efficient wire processing. Multi standard ferrules on reel can be used universally.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

The cable feeder trolley represents an innovative solution for the efficient processing of cables with various cross-sections and quantities, especially in conjunction with the Wire Processing Center. With this additional trolley, cable processing is elevated to a new level. The trolley provides the ability to place up to six different cross-sections simultaneously, ensuring flexible and time-saving handling. Using the cable feeder trolley optimizes the entire cable processing process. The versatility of the trolley allows for efficient handling of different types of cables, be it in terms of cross-section or quantity. This helps streamline workflow and increase productivity.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Original Wire Belt dragmats offer you the highest quality with a long service life. Our weatherproof design is ideal for the uncomplicated introduction of fertilizers, granulates, seeds and sand as well as for removing and roughening plazas. The movable links adapt perfectly to unevenness and the ground. A double-sided use is possible without any problems, as is pulling by hand or by machine. They are used in the maintenance of golf, football and rugby fields, in horse stables and riding facilities and are indispensable on tennis, beach volleyball and grand courts. Optimal, particularly thorough and uncomplicated processing of your floor covering with Wire Belt dragmats.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Original Wire Belt dragmats offer you the highest quality with a long service life. Our weatherproof design is ideal for the uncomplicated introduction of fertilizers, granulates, seeds and sand as well as for removing and roughening plazas. The movable links adapt perfectly to unevenness and the ground. A double-sided use is possible without any problems, as is pulling by hand or by machine. They are used in the maintenance of golf, football and rugby fields, in horse stables and riding facilities and are indispensable on tennis, beach volleyball and grand courts. Optimal, particularly thorough and uncomplicated processing of your floor covering with Wire Belt dragmats.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Original Wire Belt dragmats offer you the highest quality with a long service life. Our weatherproof design is ideal for the uncomplicated introduction of fertilizers, granulates, seeds and sand as well as for removing and roughening plazas. The movable links adapt perfectly to unevenness and the ground. A double-sided use is possible without any problems, as is pulling by hand or by machine. They are used in the maintenance of golf, football and rugby fields, in horse stables and riding facilities and are indispensable on tennis, beach volleyball and grand courts. Optimal, particularly thorough and uncomplicated processing of your floor covering with Wire Belt dragmats.

Request for a quote

HEINZE & STRENG GMBH

Germany

Available as rings, bands , stripes or coils for all OEM specifications i.e Samp, Henrich Niehoff..-Nickel (99,2%) Copper / Elmedur in a highly demanding quality cut to exact diameter with precisely cut ends or over lapping ends, exact fit , even roundness, fast and easy exchange , reducing costs due to the very high material

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZNER MASCHINENBAU GMBH

Germany

Metzner has developed a fully automatic processing machine with outstanding cutting quality and great length accuracy for steel cable wires of up to 20 mm diameter. The steel cable wires are fed by a motorised feeding device in combination with a contact-free loop control. Then, program-controlled and positionally accurate marking tapes are applied to the steel cable – with a cycle time of less than two seconds. In addition, a wax printer marks all the fastening and processing points that will be required for subsequent processing. This labelling method is carried out in a continuous process. The cut is then made using a special cutting process. Precise length accuracy is achieved by a special laser measuring system. A material stacker with a storage area of up to 12 metres ensures that the steel cable wires are deposited in an orderly manner. All cut steel rope can be stored and sorted according to length to allow it to be removed at a later point.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

This special Metzner development is able to process cable wires with a diameter of up to 28 mm. The cycle time for this is 2000 mm / 35 seconds. The processing steps include long slitting, sawing, circumferential cutting, stripping, brushing and depositing. An integrated ink jet printer labels the cable wires with information or markings. As the heart of the processing method, Metzner uses a newly developed stripping head that combines a rotary cut with a powerful clamping and simultaneous rotation of the material. This enables a high-precision, multi-stage radial cut through the various layers of material. Microscopic quality inspection confirms that the processing is flawless with no scratches, pressure or abrasion marks. In addition to the high machining quality, the machinery also offers special precision: both the overall length and the machining position are maintained with an accuracy of 0.2 mm. The machine can process cable wires with diameters up to 28 mm.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Multiple EM 600 stations in combination with a cost-effective transfer system provide the additional benefits of the EM 700 series: higher degree of automation, no limit to the number of stations, modular and scalable, single- or double-sided processing

Request for a quote

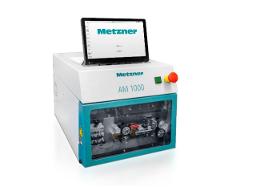

METZNER MASCHINENBAU GMBH

Germany

The Metzner AM 1000 is a sensation among the tabletop units. The automatic cutting and stripping machine processes cables, strands and wires up to 9 mm diameter and 6mm² cable cross-section with a special cutting and pull-off force (optional 10 mm², depending on material). The presettings are conveniently made via the modern 12" touch panel, where the operator can define all processes. Thanks to the sensors for diameter and material recognition, the AM 1000 works extremely precisely. Another special feature is the tool-free replacement of guides and rollers. This means that the AM 1000 can be changed over in just one minute. With the extensive interface preparation, the machine can be optimally expanded with peripheral devices and adapts to all customer requirements. The compact design with retractable touch-screen and the low weight of only 28 kg also offer special comfort. This makes the AM 1000 especially easy to transport.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The Metzner EM 300 platform offers further convenience in high-voltage cable processing through a quick change of process tools and faster cycle times. Depending on the requirements, the HV cable processing machine can thus be equipped with different tools for cable processing. This means that the EM 300 can be used for several processing steps and is prepared for a wide range of processes. In addition, with the EM 300 we protect your investment by offering improved expandability that enables “plug-and-play” integration of future new applications.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Plastic-coated steel cablestrands are cut to length using a special shear cut module and then stripped with the cutting module of the AM3500 without the wires "jumping open".Bare steel cable wires are transported by the modified AM 3500 directly to the special cutting machine, which is coupled between the AM 3500 and the material stacker and which cuts the material to length by a thermal process. Due to the special electric welding process used here, the individual wires do not twist up during cutting, and a smooth rope start and a smooth rope end without thickening are produced. Long steel cable wires/strands are placed in a tray after processing, while short pieces of material fall down a chute into a collecting container. With the high-performance solution developed by Metzner, the customer can process different types of material in different processes. Further advantages of the machinery are high precision, high quality, an increase in productivity and lower personnel costs.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner offers low-cost individual stations in the field of e‑mobility for the entry into high-voltage cable processing. For the first time, the EM 101 module offers a solution for removing the cable foil without affecting the cable shield. The automatic processing of high-voltage cable wires also necessitates the connection of various components of the connector system. The Metzner EM 102 takes care of this. The EM 103 allows the cable shield to be opened and cut using a patented process which ensures that there is absolutely no contact with the inner insulation. The EM 103S offers the functionality of the proven EM 103 to meet the requirements of smaller cable wires of up to 8 mm diameter. These cost-effective models cannot be integrated into an automation line and are equipped with only limited traceability functions.

Request for a quote

W&K METALLVERARBEITUNG GMBH

Germany

• TIG welding: The letters TIG stand for tungsten inert gas welding and generally belong to the inert gas welding process. In this welding process, an arc burns between a tungsten electrode (non-consumable) and the workpiece. The electrode, the arc and the molten bath are protected from the atmosphere by an inert gas. • MIG / MAG welding: The letters MIG stand for metal inert gas, the letters MAG for metal active gas. This welding process is also part of the group of metal inert gas welding processes. In this welding process, a consumable wire electrode is fed continuously. The arc burns between the supplied wire and the workpiece. Throughout the welding process, the arc and the weld pool are protected by either an active gas (MAG process) or an inert gas (MIG process). This welding process can be used for a variety of materials and is also available for a large number of welding consumables.

Request for a quote

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

As a manufacturer of control cabinets, we are always at your side. We process standard cabinets as well as special designs for our customers. We take care of construction and wiring plans directly according to customer specifications, as well as the mechanical processing, the construction and the wiring of the control cabinets. After the actual construction, we also carry out an electrical test and insulation tests. Upon delivery, you will receive the customer-specific labels and accompanying documents. Your advantages with A + B Electronic -Switch cabinets directly according to your specifications -We are not just a service provider, but a technology partner: A + B Electronic thinks your project with you and together we can bring it to series production successfully

Request for a quote

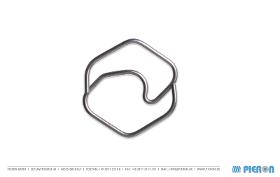

PIERON GMBH

Germany

Dimensions Wire diameter: 0,3 – 4,5 mm spring-hardened Wire diameter: 0,3 – 7,0 mm soft Part length: customer specific after consultation Profiles other than round wire after consultation Material All spring materials and quality steels with lower strengths Coating All commonly coated spring steels Additional coatings available after consultation Meeting the closest tolerances Specialities Partial machining Stamping Thread cutting or rolling Fully automated mating with other parts Mounting and component manufacturing Processing of painted wires Rapid prototyping

Request for a quoteResults for

Processing of wire - Import exportNumber of results

28 ProductsCountries