- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- procedures

Results for

Procedures - Import export

FESSMANN GMBH UND CO KG

Germany

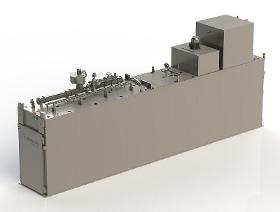

The TFi3000 Autovent is a true efficiencywonder! The patented procedure for lowpressure steam cooking without any fans at all, in combination with automated work processes, reduces the operating costs to a minimum. Cooling of the products in the closed system, directly subsequent to heat treatment, also ensures ideal hygiene conditions and increases durability. Production justintime, controllable process with reproducible work processes Automatic transport system Much lower germ formation and contamination – for longer durability Short cooking times and weight loss reduced by up to 15% Temperature difference across the system no more than 1 °C Uniform products at maximum quality due to turbulences and air velocities up to 200 m/s Very low maintenance and operation costs thanks to dispensing with fans Long service lives due to stainless steel construction and steamtight welding allround

Request for a quote

SPANDAUER VELOURS GMBH & CO. KG

Germany

Our modern machine pool allows us to produce a wide variety of three-dimensional, technical plush fabrics in different heights, yarns and fibre blends. You benefit from our many years of experience in a wide variety of applications, from painter rollers and cleaning plush fabric to plush fabric for textile washing facilities or individual solutions. We use a wide variety of natural and synthetic fibres, which allows us to find a suitable solution for every application. We also offer lint-free products, of course. In addition to our tried and tested basic qualities, we also develop individual solutions for abrasive and non-abrasive cleaning plush. We can produce plush fabrics tailor-made to your needs using a variety of yarns, fibre blends and coatings. This also includes cleaning plush fabrics for use in fully automatic cleaning systems. We make particularly hard-wearing plush fabrics for textile wash facilities, which have been specially developed for use in wet or dry

Request for a quote

TEPROSA GMBH

Germany

We offer laser direct structuring (LPKF-LDS process) for the production of 3D-MID (so-called three-dimensional circuit carriers) as a service in Magdeburg. 3D-MID stands for Mechatronic Integrated Device (or Molded Interconnected Devices). The MID technology makes it possible to use three-dimensional plastic parts as circuit carriers for electronic or mechatronic assemblies. The LPKF-LDS process is one of the technologically leading and at the same time most economically interesting process for the production of 3D-MID. The LPKF LDS process represents the central process step. The process was developed and patented by the company LPKF Laser & Electronics AG in Hanover.

Request for a quote

EBINGER KATALYSATORSERVICE GMBH & CO. KG

Germany

Step by step: From taking the test sample up to the large-scale regeneration of your catalysts Stept 1: Sample taking Let us know when a sample can be taken from the SCR reactor. We will gladly do this for you. Step 2: Analysis Why is the catalyst no longer active? By an analysis of the catalyst sample we get a general overview about the chemical condition of the catalytyst. Step 3: Diagnosis By evaluation of the chemical analysis we find out the cause of the inactivation and determine the necessary regenerations steps. Step 4: Test Regeneration / Measurement Regenerations are executed under laboratory conditions to determine the ideal regeneration procedure. Activity (k) and SO2/SO3 conversion rate will be measured after this in the bench scale. Guarantees The results of the test regeneration are the basis for the guarantee values, which are part of a regeneration offer.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK

Germany

SCHMIDT Zerspanungstechnik is the partner of choice for demanding welding solutions SCHMIDT Zerspanungstechnik's modern machinery offers a variety of welding options for the manufacture and working of components and large machine parts. As a dependable specialist in the processing of large parts, we can weld work pieces with a unit weight of up to five tons and flexibly adjust to accommodate different needs, including heat treatment and documented testing procedures: Our qualified and experienced staff are at home with various different welding techniques, such as MIG/MAG, TIG and arc welding. On request, we can carry out hardfacing of work pieces and large parts and employ special welding methods as part of the contract manufacturing service. Do you have any special wishes or requirements? We also weld custom solutions and highly complex parts with the utmost precision - on time and for a reasonable price. Our welding workshop is certified according to DIN EN ISO 3834.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BLOWERDOOR GMBH

Germany

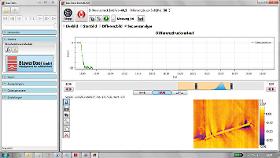

Bau.Tools BlowerDoor software has a new upgrade, offering professional thermographers even more: The differential thermography has been expanded to include sequential analysis, while the user interface has been newly designed at the same time to provide easy and intuitive usability. Bau.Tools BlowerDoor is now avalaible in English, German and French.

Request for a quote

KLN ULTRASCHALL AG

Germany

The riveting process creates irresolvable interlocking bonds. This is achieved by forming or reforming of thermoplastics. In most cases in this procedure only point-shaped or segmented joints are realized. In contrast to welding of two components there cannot be achieved hermetic joints. A particular version of this procedure is the bonding of plastics with metals, textiles and cardboard. The method is frequently used for wooden decoration parts, into which a chrome decoration strip has to be embedded. As a rule the hot form riveting is carried out in a one-cycle process. A heated riveting stamp forms the riveting head under pressure. After forming the stamp is shortly cooled down in order to avoid adhesion of the plastic material on the thermal riveting stamp. After this short cooling phase the riveting stamp is again moved above.

Request for a quote

PERO AG

Germany

The cleaning process must be designed to eliminate specific contaminants and particles from machined workpieces and parts in order to achieve the required technical cleanliness. For the wet cleaning of parts, the four parameters of the Sinner's Circle need to be combined and adjusted for optimised efficiency. PERO units offer efficient cleaning mechanics and reliable process control. According to the Sinner's Circle, the cleaning result is determined by four basic variables. By adjusting and combining these interrelated variables, it is possible to optimise any cleaning process. Good mechanical design of a cleaning unit optimises the mechanics of the process, which generally means that cleaning is completed in less time and with less resources.

Request for a quote

ATN WASSERAUFBEREITUNG GMBH

Germany

We offer a variety of special processes for removing i.a. arsenic, uranium, antimony, micropollutants and so on. Talk to us we will find a solution for your problem!

Request for a quote

ATN WASSERAUFBEREITUNG GMBH

Germany

Navigating the variety of water and wastewater treatment options available requires not only a high level of knowledge about the many possibilites available, but also consistent further development of procedures and experiences. This is the only way to maintain our high level of development and meet everincreasing demands. ATN stands for both excellent expertise and state of the art technology and equipement. The techniques available for water treatment are as diverse as the types of raw waters. This makes a conscientious and thourough consulting and planning phase all the more important. All information is considered during this phase and adapted to your individual needs, resulting in customized planning.

Request for a quote

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

Two modern AOI devices (automatic optical inspection) in 2D and 3D secure the manufacturing process during the SMT assembly. We use our X-ray inspection device to control the soldering process on components with connections under the housing. In addition to quality assurance, we also offer test and inspection procedures that are precisely tailored to your needs. In addition to circuit-specific in-circuit and burn-in tests, we can carry out application-related function tests in our test field. For specific tests, many customers send us the test procedures with the appropriate equipment directly. In this way we can check the functionality of your assembly without you having to tell us what exactly the tests are checking. Your advantages with A + B Electronic -Test procedures tailored to your needs -We are not just a service provider, we are a technology partner: A + B Electronic thinks your project with you and together we can successfully bring it into series production

Request for a quoteResults for

Procedures - Import exportNumber of results

13 ProductsCountries

Company type

Category

- Chemical catalysts (1)

- Cleaning machines, industrial (1)

- Cooking and smoke-curing equipment for delicatessens (1)

- Electrical & Electronic Components (1)

- Fabrics (1)

- Investment consultants (1)

- Laser - cutting and welding machines (1)

- Measurement - Equipment & Instruments (1)

- Milling - steels and metals (1)

- Sawmills - machinery and equipment (1)

- Telecommunications - services (1)

- Thermoforming, plastics - machinery (1)