- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure filters

Results for

Pressure filters - Import export

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: SKE-O-837 Manufacturer: Bolz Description: Pressure filter

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: EF60-125 Manufacturer: Seitz Description: Pressure filters

Request for a quote

OGE GROUP

Germany

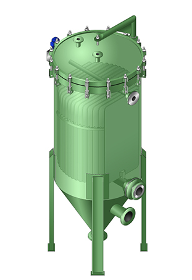

Pressure Filters The Filter is composed of a pressure tank containing the filtering elements and the washing device or dry cake removal system. The filtering elements are vertically mounted cloth covered plates in Stainless Steel/Titanium/PVC/PE/PP (so called leaves) or special candles (made in plastic materials or stainless steel).

Request for a quote

PLANET-AIR GMBH

Germany

The oil-lubricated SILVER-LINE compressor L-S50-25 is standardly equipped with a filter pressure regulator (manual condensate drain) and a 25 liter air tank.

Request for a quote

PLANET-AIR GMBH

Germany

The oil-lubricated SILVER-LINE compressor L-S200-50 is standardly equipped with a filter pressure regulator (manual condensate drain) and a 50 liter air tank.

Request for a quote

PLANET-AIR GMBH

Germany

The oil-free SILVER-LINE compressor OF-S90-15 is standardly equipped with a filter pressure regulator (manual condensate drain) and a 15 liter air tank.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quoteFAUDI GMBH

Germany

Advantages High flow rate No back flushing during the regeneration Easy discharge of the filter cake Short regeneration time Possible use of various filter belts Cleaning station for filter belts New, extremely pressure-stable design Area of application Pressure Belt Filters are used for the filtration of coolants in metal machining processes, preferable grinding sludges from rough-machining. Flow rate Various filter sizes and the modular design enable any required flow rate. Classification number - Filter aid without Filtration degree 30-100 µm Medium oil and emulsion Filter material filter belt

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

CF 30 G equipment is supplied completely assembled and ready for operation. The dust collection unit is suited for intermittent operation only, because regular cleaning of the pocket filter element in certain intervals is an absolutely must for the proper operation of the equipment. The cleaning intervals will depend on the operating conditions and must be established by experience. Normally cleaning intervals will be between operating times of 30 minutes to two hours. It is a prerequisite for sufficient and intensive cleaning of the filter cloth that dust collecting is interrupted during cleaning to achieve static pressures on the filter material. A retention time of 1 - 2,5 minutes between the end of the suction and the beginning of the cleaning process is therefore required. The filtered air must be removed outside - do not lead back to closed rooms!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FILTERTECHNIK JÄGER GMBH

Germany

Special FTJ filter fleeces are particularly suitable as precoat or support fleece on horizontal plate pressure filters or plate filters The following precoat agents are used: Diatomaceous earth Bleaching earth Cellulose Cornmeal The FTJ nonwovens Cora®Dot and Cora®Spun effect corresponding savings on precoat agents with extremely fine filtration.

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT's own filter technology is innovative and fast-growing. Why are we involved in filter technology? The answer is simple: high pressure cleaning technology using water as an environmentally friendly medium requires a high quality filter and recycling solution. In some cases, traditional filter manufacturers are unable to meet these requirements, which is why KAMAT also offers its own customer-specific solutions in the field of filter technology. High-pressure water cleaning technology has many advantages: A water jet can be used gently on the surfaces to be cleaned, water is generally available as a medium and at the same time is environmentally friendly without extensive delivery costs. When it comes to accessories, high pressure cleaning systems have special requirements that are difficult to meet. For this reason, KAMAT has developed its own customised high-pressure filter solutions. KAMAT high pressure filters are available for operating pressures up to 4,000 bar.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GLP is a pneumatic top-entry series agitator that is used for homogenizing, dispersing, emulsifying and suspending in vessels and for viscosities up to 500 mPas for instance in wastewater treatment, chemical and cosmetics as well as in food industries. The agitator speed adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight. Power transmission via elastic coupling in the bearing housing. The agitator shaft has a double bearing in an aluminum housing separated from the drive. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air, expanding in the air engine cools the agitator drive. Includes filters, pressure reducers with pressure gauge that indicates the secondary pressure. Available with a vessel clamp to fix the GLP on a drum.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GLP - Peumatic top-entry agitator The GLP is a pneumatic top-entry series agitator that is used for homogenizing, dispersing, emulsifying and suspending in vessels and for viscosities up to 500 mPas for instance in wastewater treatment, chemical and cosmetics as well as in food industries. The agitator speed adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight. Power transmission via elastic coupling in the bearing housing. The agitator shaft has a double bearing in an aluminum housing separated from the drive. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air, expanding in the air engine cools the agitator drive. Includes filters, pressure reducers with pressure gauge that indicates the secondary pressure. Available with a vessel clamp to fix the...

Request for a quote

F.E.S. GMBH

Germany

Pressure belt filters are used for cleaning contaminated cutting fluids in metal processing and rolling mill applications. Cleaned cutting fluids have longer lifespan, improve surface quality, and contribute to heat dissipation at the processing or forming point. Advantages: High throughput capacity No backwashing during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure rinsing system Affordable price Operation: The F.E.S. pressure belt filter addresses the need for filtration without disposal issues by utilizing a standard feature of a circulating plastic filter belt. A filter belt cleaning device is integrated into the head section of the belt filter. The closing mechanism of the sealing flaps, lowered pneumatic cylinders, and movable protective covers ensure a low height for easy installation and operation.

Request for a quote

BDSENSORS GMBH

Germany

PA 440 field display for for the current loop with contacts Features: — field display for pressure transmitter with output signal 4 ... 20 mA / 2-wire or 0 ... 10 V / 3-wire — 4-digit LC display — pressure compensation element with PTFE-Filter Optional Features: — IS-version — 2 contacts — 4-digit LED display — plastic housing Functionality: — free scalable display — switch mode, hysteresis, parameterizable deceleration of the contacts — no external power supply necessary

Request for a quote

BDSENSORS GMBH

Germany

The differential pressure transmitter DPT 200 has been especially designed for the process industry and can be used for level measurement of closed, pressurized tanks, pump or filter controlling, etc. The possibility passes different pressure seals at the DPT 200 adding with different membrane materials to reach an optimal adaptation to the application. Features: — differential pressure von 1 mbar bis 20 bar — static pressure bis max. 400 bar — turn-down max. 100:1 — accuracy: 0.075 % FSO — HART®-communication — output signal: linear or square root extraction — aluminium housing Optional Features: — IS-version: Ex ia = intrinsically safe Version (group II) EX ia= intrinsically safe Version for firedamp mines (group I) Ex d = flameproof enclosure (group II) — LC-Display — stainless steeel housing

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SFZ are designed for sandwich plate mounting in hydraulic and lubrication applications, with a maximum operating pressure of 315 bar / 4.560 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for sandwich plate mounting ▪ Available as left or right version Operating Pressure ▪ Max. 315 bar / 4.560 PSI Nominal Flow Rate ▪ Max. 30 l/min / 8 US GPM Materials ▪ Filter head: Free Cutting Steel ▪ Filter bowl: Cold Drawn Steel Media Compatibility ▪ Mineral oils, other fluids on request

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF Medium Pressure Filters type SMPF are designed for in-line hydraulic and lubrication applications, with a maximum operating pressure of 110 bar / 1.600 PSI. Used together with STAUFF SME series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass valve Clogging Indicator ( available as an option ) ▪ Visual or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SME series Construction ▪ Medium pressure filter designed for in-line assembly Operating Pressure ▪ Max. 110 bar / 1.600 PSI Nominal Flow Rate ▪ Max. 90 l/min / 25 US GPM Connections ▪ Option of BSP or SAE O-ring thread Materials ▪ Filter head: Aluminium ▪ Filter bowl: Aluminium Media Compatibility ▪ Mineral oils, other fluids on request

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF Medium Pressure Filters type SFA are designed for in-line hydraulic and lubrication applications, with a maximum operating pressure of 160 bar / 2.320 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ Medium pressure filter designed for in-line assembly ▪ Threaded mounting holes on top and fluid ports on side ▪ Low weight and compact design Operating Pressure ▪ Max. 160 bar / 2.320 PSI Nominal Flow Rate ▪ Max. 240 l/min / 70 US GPM Connections ▪ Option of BSP, NPT, SAE thread or SAE flange (ISO 6162-1) Materials ▪ Filter head: Cast...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SF are designed for in-line hydraulic and lubrication applications, with a maximum operating pressure of 420 bar / 6.000 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for in-line assembly ▪ Threaded mounting holes on top and fluid ports on side ▪ Option of standard or two-part top loader version Operating Pressure ▪ Max. 420 bar / 6.000 PSI Nominal Flow Rate ▪ Max. 1.135 l/min / 300 US GPM Connections ▪ Option of BSP, NPT, SAE thread or SAE flange (ISO...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SF-TM are designed for manifold block mounting in hydraulic and lubrication applications, with a maximum operating pressure of 315 bar / 4.560 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for manifold mounting ▪ Threaded mounting holes and fluid ports on top of head ▪ Option of standard or two-part top loader version Operating Pressure ▪ Max. 315 bar / 4.560 PSI Nominal Flow Rate ▪ Max. 1.135 l/min / 300 US GPM Connection ▪ BSP Materials ▪ Filter head: Spheroidal...

Request for a quoteResults for

Pressure filters - Import exportNumber of results

66 ProductsCountries

Company type

Category

- Compressors (14)

- Pneumatic systems and tools (9)

- Oiling - machines and systems (4)

- Filtering equipment and supplies (2)

- Precision measuring instruments (2)

- Filters, liquid (1)

- Air treatment - equipment and systems (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Dust extraction installations and equipment (1)

- Oil filters (1)

- Industrial equipment hire (1)

- Measurement and control instruments (1)

- Measurement and regulation equipment and instruments - pressure (1)

- Swimming-pool maintenance products (1)

- Vacuum cleaners, domestic (1)