- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure filters

Results for

Pressure filters - Import export

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: SKE-O-837 Manufacturer: Bolz Description: Pressure filter

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: EF60-125 Manufacturer: Seitz Description: Pressure filters

Request for a quote

OGE GROUP

Germany

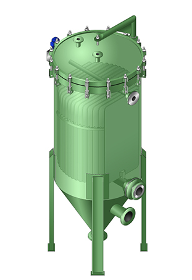

Pressure Filters The Filter is composed of a pressure tank containing the filtering elements and the washing device or dry cake removal system. The filtering elements are vertically mounted cloth covered plates in Stainless Steel/Titanium/PVC/PE/PP (so called leaves) or special candles (made in plastic materials or stainless steel).

Request for a quote

BEKO TECHNOLOGIES GMBH

Germany

The energy costs of a compressed-air system are decisively influenced by the pressure drop occurring during compressed-air filtration. To maintain the required operating pressure, this pressure drop needs to be compensated by correspondingly higher compressor performance. The consequence: increased energy demand, premature wear of the compressor ... and therefore higher costs. The better solution: CLEARPOINT compressed-air filters by BEKO TECHNOLOGIES.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

CF 30 G equipment is supplied completely assembled and ready for operation. The dust collection unit is suited for intermittent operation only, because regular cleaning of the pocket filter element in certain intervals is an absolutely must for the proper operation of the equipment. The cleaning intervals will depend on the operating conditions and must be established by experience. Normally cleaning intervals will be between operating times of 30 minutes to two hours. It is a prerequisite for sufficient and intensive cleaning of the filter cloth that dust collecting is interrupted during cleaning to achieve static pressures on the filter material. A retention time of 1 - 2,5 minutes between the end of the suction and the beginning of the cleaning process is therefore required. The filtered air must be removed outside - do not lead back to closed rooms!

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT's own filter technology is innovative and fast-growing. Why are we involved in filter technology? The answer is simple: high pressure cleaning technology using water as an environmentally friendly medium requires a high quality filter and recycling solution. In some cases, traditional filter manufacturers are unable to meet these requirements, which is why KAMAT also offers its own customer-specific solutions in the field of filter technology. High-pressure water cleaning technology has many advantages: A water jet can be used gently on the surfaces to be cleaned, water is generally available as a medium and at the same time is environmentally friendly without extensive delivery costs. When it comes to accessories, high pressure cleaning systems have special requirements that are difficult to meet. For this reason, KAMAT has developed its own customised high-pressure filter solutions. KAMAT high pressure filters are available for operating pressures up to 4,000 bar.

Request for a quote

F.E.S. GMBH

Germany

Pressure belt filters are used for cleaning contaminated cutting fluids in metal processing and rolling mill applications. Cleaned cutting fluids have longer lifespan, improve surface quality, and contribute to heat dissipation at the processing or forming point. Advantages: High throughput capacity No backwashing during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure rinsing system Affordable price Operation: The F.E.S. pressure belt filter addresses the need for filtration without disposal issues by utilizing a standard feature of a circulating plastic filter belt. A filter belt cleaning device is integrated into the head section of the belt filter. The closing mechanism of the sealing flaps, lowered pneumatic cylinders, and movable protective covers ensure a low height for easy installation and operation.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SFZ are designed for sandwich plate mounting in hydraulic and lubrication applications, with a maximum operating pressure of 315 bar / 4.560 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for sandwich plate mounting ▪ Available as left or right version Operating Pressure ▪ Max. 315 bar / 4.560 PSI Nominal Flow Rate ▪ Max. 30 l/min / 8 US GPM Materials ▪ Filter head: Free Cutting Steel ▪ Filter bowl: Cold Drawn Steel Media Compatibility ▪ Mineral oils, other fluids on request

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF Medium Pressure Filters type SMPF are designed for in-line hydraulic and lubrication applications, with a maximum operating pressure of 110 bar / 1.600 PSI. Used together with STAUFF SME series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass valve Clogging Indicator ( available as an option ) ▪ Visual or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SME series Construction ▪ Medium pressure filter designed for in-line assembly Operating Pressure ▪ Max. 110 bar / 1.600 PSI Nominal Flow Rate ▪ Max. 90 l/min / 25 US GPM Connections ▪ Option of BSP or SAE O-ring thread Materials ▪ Filter head: Aluminium ▪ Filter bowl: Aluminium Media Compatibility ▪ Mineral oils, other fluids on request

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SF-TM are designed for manifold block mounting in hydraulic and lubrication applications, with a maximum operating pressure of 315 bar / 4.560 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for manifold mounting ▪ Threaded mounting holes and fluid ports on top of head ▪ Option of standard or two-part top loader version Operating Pressure ▪ Max. 315 bar / 4.560 PSI Nominal Flow Rate ▪ Max. 1.135 l/min / 300 US GPM Connection ▪ BSP Materials ▪ Filter head: Spheroidal...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF Medium Pressure Filters type SFA are designed for in-line hydraulic and lubrication applications, with a maximum operating pressure of 160 bar / 2.320 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ Medium pressure filter designed for in-line assembly ▪ Threaded mounting holes on top and fluid ports on side ▪ Low weight and compact design Operating Pressure ▪ Max. 160 bar / 2.320 PSI Nominal Flow Rate ▪ Max. 240 l/min / 70 US GPM Connections ▪ Option of BSP, NPT, SAE thread or SAE flange (ISO 6162-1) Materials ▪ Filter head: Cast...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SF are designed for in-line hydraulic and lubrication applications, with a maximum operating pressure of 420 bar / 6.000 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for in-line assembly ▪ Threaded mounting holes on top and fluid ports on side ▪ Option of standard or two-part top loader version Operating Pressure ▪ Max. 420 bar / 6.000 PSI Nominal Flow Rate ▪ Max. 1.135 l/min / 300 US GPM Connections ▪ Option of BSP, NPT, SAE thread or SAE flange (ISO...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SF-SM are designed for manifold block mounting in hydraulic and lubrication applications, with a maximum operating pressure of 315 bar / 4.560 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for manifold mounting ▪ Threaded mounting holes and fluid ports on side of head ▪ Option of standard or two-part top loader version Operating Pressure ▪ Max. 315 bar / 4.560 PSI Nominal Flow Rate ▪ Max. 1.135 l/min / 300 US GPM Materials ▪ Filter head: Spheroidal Graphite Cast Iron ▪...

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Jerko high pressure Filter with 1/2" thread up to 16bar and 80l/min. Special design with round thread for the heavy duty environmental influences

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF provides a complete range of Spin-On filters which can be used either as suction filters or as return line filters for low pressure applications. The various ranges meet international standards. The corresponding STAUFF Filter Elements are available from stock. Clogging Indicators (available as an option) ▪ Visual clogging indicator with coloured segments ▪ Electrical clogging switch ▪ Other types available on request Constructions ▪ In-line Spin-On filter head ▪ In-line Double Spin-On filter head ▪ Tank Top Spin-On filter head Operating Pressure ▪ Max. 14 bar / 200 PSI Nominal Flow Rate ▪ Max. 460 l/min / 120 US GPM Connections ▪ Option of BSP, NPT, SAE flange or SAE thread, others on request Material ▪ Filter head: Aluminium Media Compatibility ▪ Mineral oils, other fluids on request

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF Return Line Simplex Filters SRFL-SW are specially developed for direct installation into the pipeline of industrial water cycles. Depending on their size, SRFL-SW filter housings are suitable for nominal flow rates up to 13.330 l/min / 3.300 US GPM at a maximum operating pressure of 16 bar / 232 PSI. The SRFL-SW have been designed to be used in the steel industry for pre-filtering or coarse filtering in descaling plants. For use with deminerlised water we recommend the Return Line Filters SRFL-SW in Stainless Steel. The filter element construction as a Stainless Steel basket screen filter ensures a long service life. Valves (available as an option) ▪ Drain valve Clogging Indicator (available as an option) ▪ Differential pressure gauge Filter Elements ▪ Filter elements of REL series Construction ▪ Industrial filter, designed for in-line applications in water cycles ▪ Version: Simplex Operating Pressure ▪ Max. 16 bar / 232 PSI Nominal Flow Rate ▪ Max. 13330 l/min / 3521 US...

Request for a quote

PTEC PRESSURE TECHNOLOGY GMBH

Germany

incl. check valve and filter Service pressure: 0-26 Mpa Service temperature: -40°C up to 85°C Reliable in filling and operation direction Small construction Corrosion-resistant All seals are suitable for CNG Certification: ECE R 110 The valve is equivalent of heavy metal regulation Burst pressure: > 100 Mpa, 20° Orfice diameter: 4 or 6mm, connection for 6, 8mm tube or 3/8" Filter: 50µm Dust protection cap, optional Tightness: 1x10-5mbar l/s, 20°C, 100% He

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PTEC PRESSURE TECHNOLOGY GMBH

Germany

incl. check valve and filter Service pressure: 0-26 Mpa Service temperature: -40°C up to 85°C Reliable in filling and operation direction Small construction Corrosion-resistant All seals are suitable for CNG Certification: ECE R 110 The valve is equivalent of heavy metal regulation Burst pressure: > 100 Mpa, 20° Orfice diameter: 9mm, connection for 8, 10, 12, 16mm tube or ½" Filter: 50µm Dust protection cap, optional Tightness: 1x10mbar l/s, 20°C, 100% He

Request for a quote

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

ISO groups / Filter classes ISO e PM 2.5 ISO e PM 1 / F7F9 single inserted bags with threadshaped spacers COMPOPLUS® filter media of 3layer, synthetic nonwoven electrically uncharged, organic, synthetic fibres sheet steel or plastic frame frame depth 20 or 25 mmprogressivelystructured filter media for optimum particle separation conical bag progress for an optimum filtersurface utilisation high duststorage capacity enables long filter lifetimes low pressure drop free of chemical additives

Request for a quote

MAYFRAN GMBH

Germany

This filter is used for the filtration of coolant with high flow rates. Paper- or endless belts are available.

Request for a quote

OGE GROUP

Germany

Candle Pressure Filters The Candle Pressure Filters are suited for applications requiring a high flow rate per unit area with quick cleaning features.

Request for a quote

OGE GROUP

Germany

Horizontal Pressure Leaf Filters The Horizontal Pressure Leaf Filters are an efficient system for Solid-Liquid separation where a high filtration surface is required. Easy to operate and maintain, they are essentially composed of filtering elements and cleaning devices installed in a pressure tank.

Request for a quote

OGE GROUP

Germany

Vertical Pressure Leaf Filters Dry type: The cake is removed by means of a high frequency vibrating system and is drained through the outlet flanged connection located on the bottom. Wet type: The cake is removed by means of spray jets mounted on a horizontal oscillating device with variable speed. The device cleans the whole filtering surface with strong blade jets.

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 1 part to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquid and pulverised media with fibre particles, viscous media, drain water, sludge, food etc. (plastic granulates, sand or similar media on request). Not suitable for steam. Refer to the advices on page 8! Body Stainless steel 1.4408 Sealing • Metal/metal • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4401 (316) Stem Stainless steel 1.4404 (316) Function Pneumatic single acting with spring return, normally closed (NC). Pressure discharge One-sided Pilot pressure 6bar Pilot Media Filtered and dried, slightly oiled air according to ISO 8573 (please refer to the data sheet) Pressure range Please refer to the table Temperature range • metal: on request • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 Installation Only with vertical upwards actuator The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 2 parts to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquids, drain water, sludge, food etc. (viscous media, pulverised media with fibre particles, plastic granulates, sand or similar media on request). Not suitable for steam. Refer to the advices on page 9 and 11! Body GG-25 (grey cast iron), epoxy coated 120 … 180µm (heattreatment 190°C, 20min) Sealing • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (AISI 304) Stem Stainless steel 1.4305 (AISI 304) Function Pneumatic single acting with spring return, normally closed (NC). Pressure discharge bidirectional Pilot pressure 6bar Pilot Media Filtered and dried, slightly oiled air according to ISO 8573 (please refer to the data sheet) Pressure range Please refer to the table Temperature range • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 1 part to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquid and pulverised media with fibre particles, viscous media, drain water, sludge, food etc. (plastic granulates, sand or similar media on request). Not suitable for steam. Refer to the advices on page 8! Body GG-25 (grey cast iron), epoxy coated (heattreatment 190°C, 20min) Sealing • Metal/metal • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (304) Stem Stainless steel 1.4305 (304) Function Pneumatic single acting with spring return, normally closed (NC). Pressure discharge One-sided Pilot pressure 6bar Pilot Media Filtered and dried, slightly oiled air according to ISO 8573 (please refer to the data sheet) Pressure range Please refer to the data sheet Temperature range • metal: on request • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 Installation Only with vertical upwards actuator The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 1 part to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquid and pulverised media with fibre particles, viscous media, drain water, sludge, food etc. (plastic granulates, sand or similar media on request). Not suitable for steam. Body GG-25 (grey cast iron), epoxy coated (heattreatment 190°C, 20min) Sealing • Metal/metal • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (304) Stem Stainless steel 1.4305 (304) Function Pneumatic double acting Pressure discharge bidirectional Pilot pressure 6bar (lower pressure on request) Pilot Media Filtered and dried, slightly oiled air according to ISO 8573 (please refer to the data sheet) Pressure range Please refer to the data sheet Temperature range • metal: on request • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 1 part to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquid and pulverised media with fibre particles, viscous media, drain water, sludge, food etc. (plastic granulates, sand or similar media on request). Not suitable for steam. Body GG-25 (grey cast iron), epoxy coated (heattreatment 190°C, 20min) Sealing • Metal/metal • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4301 (304) Stem Stainless steel 1.4305 (304) Function Pneumatic double acting Pressure discharge One-sided Pilot pressure 6bar (lower pressure on request) Pilot Media Filtered and dried, slightly oiled air according to ISO 8573 (please refer to the data sheet) Pressure range Please refer to the data sheet Temperature range • metal: on request • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Center body consists of 1 part to be mounted between two flanges according to EN 1092-1 type 11 form B – PN10 (former DIN 2501). ANSI 150 on request. Media Liquid and pulverised media with fibre particles, viscous media, drain water, sludge, food etc. (plastic granulates, sand or similar media on request). Not suitable for steam. Body Stainless steel 1.4408 Sealing • Metal/metal • NBR • EPDM (FKM or PTFE on request) Gland 3-piece sealing set: • 1x GFO®-Faser – TWARON® edge reinforced • 1x O-ring (NBR or EPDM or FKM) • 1x synthetic fiber, PTFE-lubricated Knife Stainless steel 1.4401 (316) Stem Stainless steel 1.4404 (316) Function Pneumatic double acting Pressure discharge One-sided Pilot pressure 6bar (lower pressure on request) Pilot Media Filtered and dried, slightly oiled air according to ISO 8573 (please refer to the data sheet) Pressure range Please refer to the data sheet Temperature range • metal: on request • NBR: -25°C … +90°C • EPDM: -35°C … +120°C Attention: Temperature range not for all media. Face to face EN 558-1 Row 20 The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice! TWARON® is a registered trademark of Teijin Aramid

Request for a quoteResults for

Pressure filters - Import exportNumber of results

30 ProductsCompany type