- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- press forming

Results for

Press forming - Import export

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

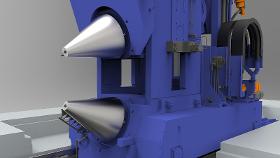

The O-forming press applies a press force of 4,000 metric tons per meter of pipe. This is necessary to form today’s material grades above X100 to the desired round shape at the optimum level of reduction. The control concept with (patented) multi-cylinder parallelism control ensures that the moving beam maintains a position parallel to the press table with a tolerance of +/-1 mm/m over the entire length. Combined with our tools, this results in a precise pipe gap which leads to signicant time and material savings for the subsequent welding process. The intelligent sensor and control concept of all main cylinders ensures that dierent sheet lengths (e.g., residual lengths) can be processed. The press is powered by either conventional drive concepts or via frequencycontrolled drive concepts. Our ECO Drive uses the high moving load of the moving beam to generate energy during the controlled quick lowering of the beam. This energy is fed back to the power network.

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

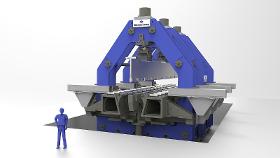

Application areas for straightening presses include the sheet metal processing industry. Here, this type of press is used for the straightening of semi-nished products, such as the levelling of uneven sheet metal and slab surfaces, which are used in subsequent processes. In addition to high straightening accuracy, Siempelkamp straightening presses provide a broad straightening spectrum and high exibility in the further processing of sheet metal. For materials with a tensile strength of 1,300 N/mm2, sheet metal with a thickness of approx. 300 mm can be processed To do so, the presses are equipped with one or several straightening rams which can be operated together or individually. The pressing force needed for straightening is applied across the entire press width. Sheet metal can be straightened by cold or warm forming with sheet temperatures of up to 600°C.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Our isothermal forging presses produce sophisticated, heavy-duty components for high-tech products. We furnish our customers with rst-class solutions including control systems for the ne-tuning of pressing speeds. Our presses are designed for high-precision applications indispensable in the aircraft/aerospace and medical engineering industries. The challenge here is to manage pressing speeds of 0.01 mm/s in controlled operation, which is ensured by our own electrical and hydraulic control engineering Siempelkamp also oers plants to be used for isothermal forging. They comprise the furnace, the feed manipulator, the forging press, the die heater, the hydraulic drive system and the entire automation technology. The plant control for isothermal forging presses monitors and documents the process parameters in compliance with the certication standards to be observed in the aircraft industry.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

As the leading provider of metal forming presses we are setting the standard worldwide. Our expertise in plant engineering and process technology is unique. This is because the individual performance features from the design to the startup of the equipment create a coherent and complete solution from a single source. Our hydraulic presses for metal forming are at home in cold and hot forming. From turbine disks for aircraft to pipeline pipes in the oil and gas industry to longitudinal beams in trucks: In our key industries of automotive, energy, rail and aerospace, we offer the right solution for every product. We supply not only the press, but also the associated process technology. Our range of services includes forging, thick sheet metal forming, raw forming, sheet metal forming and ring rolling. Our special systems for metal forming offer the perfect balance between the use of standard components and a custom-made design.

Request for a quote

SITEMA GMBH & CO KG

Germany

Generates large forces over short distances Clamping head with integrated short stroke function The PowerStroke can be used in any horizontal and vertical applications requiring large forces to be built up over short working distances.The PowerStroke can be used in any horizontal and vertical applications requiring large forces to be built up over short working distances. Series FSK, FSKP Clamping head with additional integrated short stroke function Ideal for pressing, stamping, joining, riveting, clinching, forming, embossing, closing molds etc.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis Advanz™ 6F – e170 is a heat treatable product developed for automotive skin sheet applications. This product is characterized by excellent formability and excellent hemming behavior. Novelis Advanz™ 6F – e170 is predominantly used for critical exterior closure panels, but may also be used for demanding inner applications. Typical areas of application are hood outers, door outers, fenders, deck lids and critical inners. This product offers best in class forming behavior during press forming and exhibits significantly improved hemming properties over standard outer sheet. All values listed are typical.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). At PRUFREX, single-chamber and multi-chamber coils can also be achieved using two-wire windings. For specific magnetic flux requirements, we apply wires of different thicknesses to the coil form. Two different wire thicknesses, from 0.045 to 0.71 millimetres, on coil forms with press-in ferrite or metallic cores.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of all important parts Maintenance of mechanical and industrial machines Advantages and benefits Long and strong hand lever with plastic grip Grease press barrel smooth and without internal profiling Stable grip at the plunger rod that prevents bruising Grease press barrel and rear cover form a unit (in order to prevent accidents) Limit stop for the plunger rod Mounting of firm nozzle tubes easily possible Suitable for grease up to NLGI 3

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

The GESIPA® TRI-FOLD® blind rivet forms three press lashes on the closing head side during setting. The advantages The large moulded lashes distribute the exerted clamping force evenly and gently onto the riveted material. Also, the large surface of the lashes offer excellent protection against the rivet being pulled through very soft, porous or brittle application parts. Thanks to its special design, the TRI-FOLD® is also able to compensate over-dimensional or irregular drill hole diameters. Application areas TRI-FOLD® blind rivets are excellently suited for the automotive field, e.g. for plastic panelling, car body parts and for the interior work inside vehicles, but also for all other applications that are particularly soft, brittle, easily deformed or porous.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

The RUF briquetting systems of the Biomass series process dust, shavings and wooden chips into briquettes of consistently high quality and density. Varying bulk densities are offset automatically during the process. These materials can be pressed into a compact form without the use of binders. It is important that the moisture content of the chips is below 15%, preferably under 12%, and that the chip size does not exceed 50mm. The general rule is that the finer the material is, the smoother and more solid the surfaces and edges of the resulting briquette. The systems can be equipped with a multitude of options, thus optimally adapting them to customer needs. This series offers maximum flexibility. All systems are extremely energy efficient thanks to the innovative RUF hydraulic system. Depending on the model, the machines are equipped with motors ranging between 4 kW and 90 kW. The throughput capacities of the RUF Biomass presses range between 50 and 1,300 kg/h.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

This hydraulic crimper with patented C-form pressing tool facilitates the radial infeeding of complex hose assemblies. It is particularly well suited for hoses used in automotive manufacturing. * According to the fitting

Request for a quote

FRIMO GROUP GMBH

Germany

Hydraulic presses for a broad variety of pressing, foaming, punching and forming tasks FRIMO HyPress standard machines can be adapted to fit table size, stroke, clearance, and press force requirements. Numerous options are available including safety packages, pivoting rams and tables, tool change systems, automation solutions, and complete customizations. The standard presses are designed as bolted, welded structures. The machine feet, head and sides are manufactured with high precision and fastened with fitting keys. The ram is guided via prisms and can be easily readjusted. It can alternatively be column-guided.

Request for a quote

FRIMO GROUP GMBH

Germany

"Combi" tools allow different technologies to be combined in a single step (in one tool) for more efficient plastic component production. Typical technologies applied in combined processes (depending on the requirements) are foaming, forming, laminating, edge folding, punching and joining. These processes allow different materials and material combinations to be used. "Combi" tools enable a very fast and cost-effective production process with minimized space requirements. Based on their longtime expertise and completion of numerous serial projects, FRIMO is able to supply optimized tooling solutions that perfectly meet the product and customer requirements. These range from small tools to special tools for large components for a nearly unlimited range of plastic applications. Our tools are available in steel or cast steel, as well as in aluminum, cast aluminum or nickel shells. For special applications, FRIMO also offers tools with interchangeable inserts, allowing the most efficient

Request for a quote

FRIMO GROUP GMBH

Germany

The combination of multiple technologies/procedures in one step is called OneShot technology. Semi-finished products (e.g. renewable raw materials such as natural fibers) and decorative materials (e.g. textiles) have to be handled in one production step to finish a component, such as a door panel. FRIMO has developed a modular system that allows for simple and customized configuration of a OneShot plant with all necessary tools. The following units can be integrated into such a plant: feeding station, heating station, calibrating station, material assembly station, press with OneShot tool, part-removal station.

Request for a quote

FRIMO GROUP GMBH

Germany

Composites are engineered materials made from two or more materials with significantly different physical or chemical properties. Their mechanical and physical properties depend on the type and proportion of the base materials and the parameters of the manufacturing process. Due to composites, very light and durable plastic parts can be produced. Composites may be prepared as layers , fibers, particles or penetrating composites , but the actual composite material usually only arises during the shaping process in the tool . FRIMO has extensive technical expertise and many years of experience in developing and manufacturing plants and tools to process composite materials such as CFK, GFK, NFPP, HFPP, LFT, GMT and BMC and supplies for the production processes such as RRIM, SRIM / GMPU, Long Fiber Technologies, NFI, or RTM tailor-made manufacturing equipment.

Request for a quote

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser supplies high-precision mechanical presses for sheet metal forming. The decades of experience and the technical execution of the stamping and forming machines guarantee exceptional precision, high productivity and reliability as well as a significant reduction in operating costs. However, a forming line consists not only of the press but of a number of ancillary equipment and auxiliary units, which only result in a functioning system as a whole. We have more than 70 years experience in the integration of press and peripherals. Our experts know exactly the mutual dependencies and requirements of the individual sub-systems. Profitability and productivity are the result of an optimally coordinated system. We are happy to advise you on the planning of your forming plant. However, a forming line consists not only of the press but of a number of ancillary equipment and auxiliary units, which only result in a functioning system as a whole. We have more than 70 years...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser is among the most experienced suppliers of presses and automation for sheet metal forming on the market. High precision, long lifetime of machine and tool, and low maintenance costs speak for the quality of our machines. ANDRITZ Kaiser produces customized solutions for every application – from the stand-alone press or roll feeder to complete production lines with coil handling equipment, finished part handling, scrap handling, and automation system. With over 8,000 automatic punching and metal forming presses worldwide, our customers produce high-quality formed and punched products. Our sheet metal forming solutions find applications in the automotive (OEMs and suppliers), white goods, electronics, electromotor lamination, construction, and consumer goods industries. Numerous well-known companies place their trust in our equipment. Our range of products Complete production lines for blank cutting, electromotor lamination, or conventional stamping Automatic...

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

With the ring rolling mill Siempelkamp completes its range of products for the manufacture of rings. From forging the pre-forms to manufacturing the ring blanks to ring rolling, we supply everything from a single source. Siempelkamp’s ring rolling mill manufactures seamless rings made of steel and special materials such as nickel-base, titanium, or aluminium alloys using maximum radial and axial pressing forces. The radial pressing force is hydraulically generated and applied to the part via a mandrel roll. Radial rolling is carried out by reducing the roll gap between the driven external roller and the mandrel roll. The axial pressing force is also hydraulically generated and applied to the part via the upper axial roller. Axial rolling is carried out by means of the vertical forward feed of the upper axial roller. A centring device provides for the correct position of the ring during the rolling process.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp is number one in tailor-made plants for the leading manufacturers of pipeline pipes. These large-diameter pipes with longitudinal weld seams are manufactured using crimping, U-forming, and O-forming presses. Compared to other processes on the market, these three presses achieve high production outputs of up to 30 pipes per minute regardless of the pipe diameter. For these large presses featuring our proven metal frame construction, the heavy component parts and tools are manufactured in our in-house foundry. The three hydraulic presses present the essential forming units of a modern production line for longitudinally welded pipes with lengths of up to 18 m in three forming steps. For each of the three forming steps, Siempelkamp oers the optimal press and the associated equipment for the forming line (e.g., pipe transport, lubrication, measuring).

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

A press for all processes Beside the pressing systems for industrial production, Siempelkamp manufactures laboratory press systems – both “try-out” presses for laboratoryscale tests with a starting pressing force of 150 t as well as presses for “fullscale testing”. The laboratory press systems are designed for maximum exibility. With it, all processes of composite production can be investigated. For example, it can be investigated whether press technology is an economic alternative for “autoclave” processes. All processes SMC with glass ber or carbon ber RTM PCM Organo-sheet consolidation Thermoplast forming Hybrid forming Integrated molding and joining of hybrid materials All control methods Force control with position monitoring Position control with force monitoring Each process step can be individually dened and programmed: All relevant process data are recorded and displayed.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp hydroforming presses are used for the production of complex and intricate workpiece shapes. This complexity relates to both longitudinal and cross sections. Next to large batch production in the automotive industry, the tting industry is one of the numerous application areas for this type of press. Compared to conventional forming methods, the forming possibilities are signicantly increased when forming with high pressure. Features hydraulic clamping forces: < 100 MN high pressure intensier: < 10.000 bar axial forces / axial cylinder: < 5 MN short cycle times due to "quick lling" systems Advantages weight savings of 40 to 50 %, in some cases up to 75 % wall thickness distribution optimized to component requirements high work-hardening continuous material grain ow for optimum component performance high dimensional accuracy

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Our open-die forging presses play an important part among the forming presses. Siempelkamp supplies complete open-die forging presses equipped with manipulators and ancillary equipment such as lifting turntables and quite a number of additional components. Our presses operate reliably, fast and precisely, operating at pressing forces between 10 and 160 MN. The range of presses available comprise push-down or pull-down designs, two- or fourcolumn designs with oil-hydraulic or water-hydraulic drives. High-stroke frequency contributes to the eciency of these presses. Our customers produce bars, discs, rings, and anges from materials such as steel, high-alloy steel, nickel-based alloys, titanium, and aluminium on these presses. They prefer to order turn-key plants including integrated manipulators, turntable, die magazine, and die-changing system.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The ContiRoll® press is the core element of the forming and press line and at the same time the focus of Siempelkamp’s innovations. More than 300 presses have been sold to all parts of the world since its launch 30 years ago. The concept has been continuously developed by Siempelkamp ever since, especially product quality, user friendliness and resource eciency. The exible infeed section adjusts to the formed mat in dependence on the recipe thus oering an optimal combination of a quick pressure build-up and a reliable evacuation of air from the mat. The booster heater integrated in the infeed end transfers a maximum of thermal energy into the mat. Very fast pressure and temperature build-up ensure an optimal density prole and excellent physical properties of the engineered board. Today, the 8th ContiRoll® generation is in use. It oers almost isobaric pressure distribution. Patented pressure distribution plates ensure consistent pressure in working direction acting on the product.

Request for a quote

ULBRICH GMBH

Germany

We build production-presses in form of column-presses, pillar-presses etc. after your specification up to a max. force of 1600 tons. According to customer-wish with simple, doubles or triply cylinder system.

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Chemical Process Industry / Oil & Gas Industry Our vacuum and compressor systems maximize output and efficiency while minimizing maintenance and environmental pollution. Made of stainless steel and other sophisticated materials, they handle explosive and corrosive gases safely and efficiently. Pulp & Paper Industry Providing vacuum pumps and related equipment to the pulp & paper industry is a Gardner Denver Nash specialty. We are well known as an industry leader in engineered vacuum systems and water removal for paper machines. NASH vacuum pumps are used throughout the forming and press sections of a paper machine. Power Industry For over half a century, NASH has been the manufacturer of choice for air removal systems in steam cycle power generation plants throughout the world. NASH condenser exhauster packages efficiently remove inward air leakage from the condenser and improve the efficiency of the turbine under all operating conditions. Other Industries For more than 100 years, Nash has engineered liquid ring vacuum pumps, liquid ring compressors and engineered systems for the toughest applications. Our systems operate dependably for decades in filter applications, refineries, the sugar industry, in the food processing industry, mining and many more applications.

Request for a quoteResults for

Press forming - Import exportNumber of results

27 ProductsCountries

Category