- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- paper manufacture

Results for

Paper manufacture - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel cnc machining.

Request for a quote

KNÜPPEL VERPACKUNG GMBH & CO. KG

Germany

Intermediate layers of corrugated cardboard separate the individual pallet layers and prevent them from slipping.

Request for a quote

KNÜPPEL VERPACKUNG GMBH & CO. KG

Germany

Intermediate layers of grey cardboard separate the individual pallet layers and prevent them from slipping.

Request for a quote

KNÜPPEL VERPACKUNG GMBH & CO. KG

Germany

PadPak Junior converter paper on a roll with a grammage of 70g/m².

Request for a quote

KNÜPPEL VERPACKUNG GMBH & CO. KG

Germany

Paper for the FillPak TT paper filling system in fanfold.

Request for a quote

KNÜPPEL VERPACKUNG GMBH & CO. KG

Germany

High quality kraft paper for the operation of the WrapPak®Protector paper cushioning system.

Request for a quote

KNÜPPEL VERPACKUNG GMBH & CO. KG

Germany

PadPak Senior 2-ply paper on roll for our PadPak Senior converters.

Request for a quote

KNÜPPEL VERPACKUNG GMBH & CO. KG

Germany

The strong packaging paper blanks for all applications where a stronger paper is required.

Request for a quote

KNÜPPEL VERPACKUNG GMBH & CO. KG

Germany

Slip-resistant intermediate layers made of paper secure the load against slipping during transport.

Request for a quote

BAGOBAG GMBH

Germany

The Paper Sack Is Back: Renaissance of the Printed Paper Sack in Retail Sales: For a long time, paper sacks weren't making much of a splash. Assumed to be disposable bags, plastic sacks and cotton bags dominated the streets. Discounters and supermarkets offered plastic sacks by the thousands to their customers at the counter. But with the population's growing ecological awareness, paper sacks have returned to their previous place of significance. Since owners don't give out free bags anymore to package goods, the customer is the one who chooses and often prefers paper sacks. As anyone who has used them knows, they are unexpectedly robust even under heavy loads. Marketing departments have also discovered how inexpensive paper sacks are as effective advertisements, combining promotional potential for the business with value for the customer. Supermarkets, retail stores, and their agents are printing paper sacks in mass numbers again. Printed paper sacks with logos are absolutely...

Request for a quote

BIO STROHHALME GMBH

Germany

Allover-print on Paper Drinking straws Sustainable paper drinking straws are not only a mere straw but a stylistic element in your CI or with your logo, slogan or statement. On the one hand, they are indispensable sanitary product but, on the other hand an expression for individuality and lifestyle. Our paper drinking straws are sustainably manufactured and 100% biodegradable after use. With 48 colors and ca. 10 standard designs in different sizes we already offer more than 700 options and designs – but, with your straw, you are setting an example! A paper drinking straw with your logo or in your CI thus becomes an individual promotional product – “advertising on everyone´s lips”. Available straws Straight: ca 6 x 210 mm + 6 x 250 mm MOQ: 35.000 straws Straight: ca 8 x 200 mm + 8 x 250 mm MOQ: 32.500 straws

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Recovery of flexoprint dye Picture: printing dye (red); ultrafiltrate (orange); nanofiltration permeate (clear) Application: Conditioning and concentration of cardboard printing dyes (flexo print), e.g. paper bag manufacturing, corrugated board manufacturing. Conditioning of the rinse waters by ultrafiltration(UF): Recovery and recycling of dyes, separated by tonality Further conditioning of the permeate by nanofiltration(NF): Recovery of the rinse water Further conditioning of the UF-concentrate by evaporation / distillation as pre-stage for external disposal Advantages of the process: Recovery of dyes separated by tonality is possible and established Recirculation of the rinse water is possible and established Reduction of the waste water amount At existing waste water treatment plants (based on precipitation) amounts of sludge can be reduced enormously Compact and modular design Fully automized process - low personnel costs High degradation rate and efficiency (concerning CSB, Cu,

Request for a quote

J.D.F. IMPORT-EXPORT GMBH

Germany

tem copy paper Material 100% virgin wood pulp Size A4, A3, 8.5x11,8.5x14 Base Weight 80gsm, 75gsm, 70gsm Whiteness 102%-104% 110% Packing 500 sheets per ream, 5 reams per carton(box) Load Qty(20ft) GSM A4 A3 8.5x11 8.5x14 80gsm 7800 reams 4000 reams 8200 reams 6300 reams 75gsm 8000 reams 4100 reams 8500 reams 6500 reams 70gsm 8200 reams 4200 reams 8800 reams 6700 reams Key performance No jam in photocopy machine No double feed Stay flat after copying Leave no dust in the copy-machine Nice appearance-white and clean Nice touch-smooth and bulky No see through-print both sides Been developed for: Photocopy Machines, Laser Printers, Ink-jet Printers, Fax Machines

Request for a quote

DSMART GMBH

Germany

Production Process of kraft paper bag with zipper and window A: Artwork confirmation B: Printing cylinders making C: Prepare raw material accordingly D: Printing E: Lamination F: Slitting or folding G: Bag making/cutting H: Final inspection J: Delivery Other information of kraft paper bag with zipper and window A: We are specialized in making all kinds of packaging materials, such as food bags, coffee bags, zipper bags, ziplock bags, stand up pouches, black bottom bags, aluminium foil bags, pet food bags, tobacco bags, fruit packaging bags, vegetable packaging bags, paper bags, tin boxes, hole puncher for plastic bags. B: We do printing according to your design artwork, just send us layered design in AI or PDF or PSD format. C: The MOQ is 10,000 pcs, the more the cheaper D: Similar samples are available Disclaimer: All trademarks and pictures shown here are as example of our production capability, they are not for sale, and they are the property of their owners.

Request for a quote

GARNTEC GMBH

Germany

Diameters from 1,8 mm up to 30 mm! Our paper cords are made of high-quality craft papers and can be supplied in soft and hard version. Conditioning of cross spools up to 100 kgs. In additional the parallel wound cords can be supplied as rings or on plastic-, metal-, or wooden drums. By application of most commonly used wooden drums it is possible to use GarnTec filling strings in the stranding machines. Range of application: - telephone cable, energy cable and special cable manufacturing, as center string, filling string or blind string - to bundle up paper and waste paper - paper handles for paper bag manufacturing - as decoration material - to close garbage bags - packaging networks and packaging bars manufacturing - as packing material in all paper areas - in turn-up-systems of paper machines - paper webs as fabrics for furniture, doors and room dividers

Request for a quote

GARNTEC GMBH

Germany

Decoration Yarns made from paper - Creation in all colours! GarnTec Decoration-Yarns are suitable for tinkering or in the floristic due to the simple handling. Manufactured from paper and fine wires our yarns are pollution free and biologically degradable. Diameters of 0,8 mm with 0,4 mm wire or 1,5 mm with a wire inlay of 0,4 mm or 0,6 mm are available. The yarns will be supplied on coils with different length. Naturally we can supply cut length, multiple yarns, paper tapes and paper cords for decoration.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA NONWOVENS GMBH

Germany

The modular design of the OPTIMA PAKSIS D5 allows customization for individual packaging needs. The stacker, fully equipped with two manual filling stations, is often used at the beginning of a diaper production. As the need for automatization rises, the base bagger can be added from the beginning or at a later point in time. Designed and manufactured in co-operation with Fameccanica Data S.p.A.Modular machine structure Sturdy design

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA OSR bag packer and packaging machine can handle tissue products of all types, supporting all required roll product formations of kitchen towels and bathroom tissue in one or multiple layers. Optima Nonwovens machines and modules are designed to meet your specific requirements. Bathroom tissue and kitchen towel rolls can be packed on Optima equipment in pre-made polyethylene bags. This is how Optima Nonwovens has maintained its status as a leader in the industry. Full servo technology Modular machine structure Taylor made solutions to match individual requirements Small foot print Quick and easy change-over Single and double layer packages possible Premade polyethylene bags on wickets Point of sale packages Carry-handle possible Perforation for easy bag opening possible

OPTIMA NONWOVENS GMBH

Germany

Fully integrated counting, stacking, and packing machine for maximum process control and operability. The Packaging Machine OPTIMA PAKSIS A6 assures quick and easy installation and start up. Full servo technology for all operating units to provide maximum flexibility for diverse packaging requirements as well as quick change overs. The OPTIMA PAKSIS A6 offers a sturdy design and easy accessibility to the process units. All parts in contact with the product are designed in stainless steel or surface coated. Designed and manufactured in co-operation with Fameccanica Data S.p.A. Further information is also available at PAKSIS A6 - Breakthrough packaging systemsOptimized process control Full servo technology Quick and easy change-over Sturdy design

OPTIMA NONWOVENS GMBH

Germany

Whether compressed large packages or sales packages with excellent visual and haptic quality, this segment is characterized by strongly varying requirements. Modular packaging machines such as the OPTIMA LS/OS8 can meet all these needs at the same time. Industry-leading outputs combined with very high machine reliability ensure productivity, while additional quality control functions for both, process and product, further sets these units apart from the competition. The OPTIMA OS8 bagger can be ideally combined with the OPTIMA LS stacker. Not only can an unrivalled range of formats be flexibly processed with this system; the integrated modules and additional (control) functions open up a new dimension of packaging process design. Modular machine structure Multiple product rows possible Stack turning possibility Quick and easy change-over Premade polyethylene bags on wickets

OPTIMA NONWOVENS GMBH

Germany

Fully integrated counting, stacking, and packing machine for maximum process control and operability. The OPTIMA PAKSIS D7 assures quick and easy installation and start up. Full servo technology for all operating units to provide maximum flexibility for diverse packaging requirements as well as quick changeovers. The packaging machine OPTIMA PAKSIS D7 offers a sturdy design and easy accessibility to the process units. All parts in contact with the product are designed in stainless steel or surface coated. Designed and manufactured in co-operation with Fameccanica Data S.p.A. Further information is also available at PAKSIS D7 - Breakthrough packaging systemsOptimized process control Full servo technology Quick and easy change-over Sturdy design

OPTIMA NONWOVENS GMBH

Germany

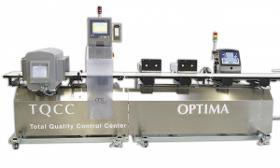

Metal detection based on measurement of magnetic permeability Check-weighing process with industrial load cells Rejection pushers mounted on a separated frame to avoid any vibrations 5 separate servo driven belts Interface between TQCC and bagger included One HMI for metal detector, check-weigher and rejection Modular design for easy service

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA OS5 bag packer and packaging machine offers a new method for packaging tissue paper into either polyethylene bags or polyethylene film with the integration of reasonable product compression during the packaging process. The final packed product comes out as a nice, tight, compact package which is easy to palletize. Carton boxes for the secondary packaging are not needed anymore. The press capacity allows perfectly adapted product compression without any quality deficits. Due to the tight and compact film package, the number of truck loads required for transporting only the packaging material is significantly reduced as well as for the transport of the final package. Altogether, the new packaging method gives a high potential in cost saving on packaging material warehouse storage, shelf space and logisitcs and it is environtmentally friendly. Quick and easy change-over Premade polyethylene bags on wickets Carry-handle possible

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA WWM loads pre-packed wet wipes into PE bags. The machine concept is based on the LBV series which can be found in most of the countries around the globe. Packaging of paper hygienic products asks for minimum volumes at maximum speeds. From standard machines to high-performance packaging lines, machines from Optima Nonwovens are modular in construction and allowing to implement your special requirements. Secondary packaging of pre-packed wet wipes Handling of up to 4 rows possible Quick and easy change-over Cross direction feeding of pre-packed wet wipes

OPTIMA NONWOVENS GMBH

Germany

For packaging light incontinence products, high performance and a huge variety of packages are in demand. Adapted to these requirements, the OPTIMA HS/OSI bag packer and packaging machine offers maximum flexibility and ideal product protection. Stackers from Optima Nonwovens can synchronously accommodate the infeed of incontinence products from manufacturing machines. The products are counted by the stacker and arranged in pre-defined layouts. As the link to the packaging machine, the stacker quickly and gently supplies the products to the further packaging process. The OPTIMA OSI bagger delivers high outputs and can accommodate an extremely broad range of formats and larger packages. Modular machine structure Quick and easy change-over Multiple product rows possible Tilting cassette Premade polyethylene bags on wickets

OPTIMA NONWOVENS GMBH

Germany

For packaging baby diapers and training pants, high performance and reduced package dimensions are in demand. Adapted to these requirements, the OPTIMA LS/OS3 packaging machine offers maximum flexibility and ideal product protection. Modular machine structure Taylor made solutions to match individual requirements Quick and easy change-over Premade polyethylene bags on wickets User friendly touch screen Designed for easy maintenance

OPTIMA NONWOVENS GMBH

Germany

The OPTIMA HS/OS7 bagger and packaging machine combines multiple decades of experience as the technological leader with unrivalled quality in machine engineering. The user’s individual requirements set the standard for how the packaging process is designed. With these high-performance machines, a multitude of new options are possible in the packaging process, for example for producing small packages at high speed. Multiple stack handling options Low count tilt module for low count bags Automatic lubrication system Motorized change-over High speed packaging

OPTIMA NONWOVENS GMBH

Germany

High packaging quality is always the crucial factor. The OPTIMA HS/OS3 bag packer and packaging provides the right packaging to best showcase logos and printing at the point of sales. The adjustable high compression further enhances quality and brings with it a number of advantages in logistics. Optima Nonwovens packaging machines are flexible: The machines can be adjusted quickly and easily for a large range of formats, format sets and modules. Fully automatic high-speed stacker for baby diapers Quick and easy change-over Quality gate Modular machine structure Designed for easy maintenance

Results for

Paper manufacture - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Paper and cardboard manufacturing - machinery and equipment (13)

- Paper, packaging - manufacture (10)

- Paper - manufacturing machinery (5)

- Paper, stationery - manufacture (2)

- Paper, printing - manufacture (1)

- Paper, special and technical grades - manufacture (1)

- Cables and wires, electric and telephone (1)

- Gardening and horticulture - equipment and supplies (1)