- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vibrators

Results for

Vibrators - Import export

HOCHRAINER GMBH

Germany

The availability and output of a production system is only as high as the process reliability of its feeding systems allows. Thanks to more than 35 years of experience as a system supplier for assembly technology and custom machines, we can implement a large variety of applications tailored to customers' requirements;

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

Rotating Piston Absorbers are displacement absorbers using hydraulic flow resistance. They are used to damp rotational vibrations, e.g. absorbers for ropeway cabins (see VDIRichtlinie VDI 3833 German Association of Engineers, sheet 1). The design is customized. Due to different operating conditions, no standard design is possible. (see also VDIGuideline, VDI 3833 sheet 1)

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

Vibration absorbers are produced in several configurations SINGLE TUBE VIBRATION ABSORBER for pull and push absorption at random mounting positions. The length is increased to keep the diameter dimension at a minimum. TWIN TUBE VIBRATION ABSORBERS for pull and push absorption. The preferred mounting position is vertically aligned. Compared to single tube absorbers, the length is decreased, while the diameter is enlarged. The characteristic of damping for both types can be progressive or degressive. (Detailed information concerning application and calculation can be found in the VDIGuideline VDI 3833 Bl.1+2 – German Association of Engineers Guideline.)

Request for a quote

HOCHRAINER GMBH

Germany

The availability and output of a production system is only as high as the process reliability of its feeding systems allows. Thanks to more than 35 years of experience as a system supplier for assembly technology and custom machines, we can implement a large variety of applications tailored to customers' requirements;

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

Based on a individual needs assessment we tailor-make briquetting solutions including peripheral devices.

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

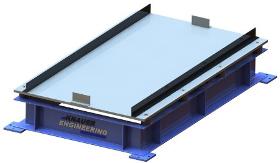

To view and download the brochure please click on the left image. Video Vibrating table to compaction of materials Video Vibrating beams to produce concrete elements

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

To view and download the brochure please click on the left image.

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

To view and download the brochure please click on the left image. Vibrating table for the produktion of prefabricated mineral cast This plant has been developed for the company EPUCRET for the production of machine frames out of mineral casting. EPUCRET has been active for over 20 years at the cutting edge of polymer-bonded mineral casting technology and offers its customers from the mechanical, plant and appliance engineering industries a competent all-round service for system solutions using mineral castings. (for further information see www.epucret.de). During the development of the machine it had to be considered that the production program reaches from small over medium sized to large products und that these had to be produced efficiently on this plant. The plant consists of 2 vibrating table which are suspended by air springs and which can be run simultaneously or independently. The working level is being kept constant by a level control. During the production of small and...

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

We offer custom made vibrating Systems, tailored to our customers Needs.n

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

KNAUER Vibrating tables are used in many fields of various industries, such as Compaction of concrete elements, fast and economic filling and emptying of containers with bulk goods, sorting and distributing of bundled tubes or similar elements. Besides some standard vibrating tables most vibrating tables are being designed and manufactured according to customer requirements. From small, simple vibrating tables up to very large tables with, e.g. hydraulic mould clamping, electronic amplitude adjustment and automatization.

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

For KNAUER ENGINEERING-Vibrating Tables there are many fields of application in several industry branches. Examples: • Compaction of concrete elements • fast and economic filling and emptying of containers with bulk goods; • deairation of viscous liquids; • sorting and distributing of bundled tubes or similar elements. Besides some standard vibrating tables most vibrating tables are being designed and manufactured according to customer requirements. From small, simple vibrating tables up to very large tables with, e.g. hydraulic mould clamping, electronic amplitude adjustment and automatization.

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

The H igh F requency vibrators of this series have to be operated with a frequency converter or inverter. If operated with a frequency inverter an rpm adjustment can be realised with little effort. Matching standard or custom made power supplies for the vibrators can be offered. Special Features are: • Centrifugal force from 4 kN to 20 kN • Speed from 1000 RPM to 6000 RPM

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

Due to an elastic swivel joint on the mounting base of this vibrator series an elliptical, almost linear force is being generated instead of the circular force of normal vibrators. For some applications this allows to use only one vibrator of this series instead of two normal vibrators. Fields of application are e.g.: Vibrating troughs and screens, Bunker vibration, shaking stations. Special Features are: • Centrifugal force from 2 kN to 39 kN • Speed from 1500 RPM to 3000 RPM

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

The very robust design allows extremely high mechanical and electrical (Heat) loads, which occur in machines with e.g. very short cycle times. Fields of application are e.g.: Table vibration of block making and pipe machines, etc, knock out grates, Vibrating beams. Special Features are: • Centrifugal force from 14 kN to 40 kN • Speed from 1000 RPM to 3000 RPM

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

The compact design allows to generate high centrifugal forces and requires minimum space. This is often necessary when used in machines. Fields of application are e.g.: Ram vibration of block making machines, vibrating table, battery formworks. Special Features are: • Centrifugal force from 0,5 kN to 16,5 kN • Speed from 1500 RPM to 3000 RPM

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

The range of external vibrators from Knauer Engineering includes normal frequency, high frequency and oscillating vibrators in various executions for applications in the construction and concrete industry as well as in other industries. Besides the proven vibrator system of Losenhausen, Knauer Engineering also offers now a considerably vibrator program for multi-purpose working areas. Applications are used in Construction industry, Industry of building materials, Mining-, Chemical-, Packaging and food industry, mechanical engineering as well as quality inspection and quality assurance.

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

Vibrating tables suitable for testing and quality inspection of sensitive components The vibratingsystems are employed for simulation of stress created by mechanic vibrations on mechanical and electrical components and subassemblies with the following features: Direction of oscillation: linear - horizontal (sinusoidal oscillation), adjustable by means of a selector. Either oscillation in x-axis or alternatively in y-axis

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our cable protection program for noise reduction / vibration protection impresses with its high flexibility and high mechanical strength. It enables fast cable pulling and reliable protection of the cable in areas with strong vibrations. The corresponding, wide range of accessories can also be found in our product portfolio.

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

Sensors and accessories for vibration measurement and Condition Monitoring Large selection of vibration sensors accelerometers, displacement sensors, VIBCODE transducer and triaxial sensors Accelerometers measure vibration acceleration, shock pulse (roller bearing condition) and pump cavitation Also available in compact size, for lowspeed machines and as combi sensors for vibration and temperature Patented tandempiezo technology eliminates the disadvantages of conventional sensors Highquality signal transmission over long distances up to 1,000 meters (3,200 feet) with current line drive (CLD) signal amplification Various mounting types EX / ATEX versions available Temperature probes, keyphasers, cables, adaptors and tools available

Request for a quote

IBG HYDROTECH GMBH

Germany

The removal of mineral deposits, concrete, slag, filling compound or similar substances in pipe and sewer systems is made possible by this newly designed nozzle. The substances are separated in their structure by the vibrations in a specific frequency field and detached from the pipe wall. In particular, drainage pipes in landfill or tunnel areas can also be cleaned without any problems. - Not suitable for vitrified clay or clay pipes.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

With VIBRONET Signalmaster, up to 162 measuring points can be installed and entire production areas can be included in the monitoring. The distance between the basic unit and the sensor does not play a decisive role, because the wiring concept used reduces installation costs to a minimum. VIBRONET Signalmaster is therefore one of the most efficient and costeffective monitoring systems for large machinery and extensive plants with productioncritical units. Vibration, temperature, RPM and other process parameters can be integrated into a monitoring network that covers whole plant sections.The robust cabling installation guarantees reliable machine monitoring even in harsh environments such as cement plants, openpit and underground mining or refineries. VIBRONET Signalmaster is easily expandable. The data recorded can be analyzed in OMNITREND CENTER, the universal software platform for PRUFTECHNIK's Condition Monitoring systems.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

Safe, simple, precise The new VibScanner 2 Ex is a nextgeneration, explosion protection system for quickly detecting machine vibration in hazardous work environments. Measuring simultaneously on three axes, the VibScanner 2 Ex sets the benchmark for fast and accurate measurements of machine, gear, and bearing issues. This is the ultimate tool for fast and accurate machine vibration measurements. The VibScanner 2 Ex heightens efficiency and data quality. In just a quarter of the time of a standard datacollector, it precisely measures available data in three axes. Equipped with a triaxial sensor, it requires only one measurement point and the click of a button to begin collecting machine data. This device is ideal for routebased maintenance jobs in environments where explosion protection standards are required. Its rugged magnetic foot of the triaxial sensor fits perfectly on the housing of any motor, pump, fan, or other rotating device, detecting vibration right near the source.

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

Vibration analysis in explosive environments VIBXPERT EX is a highperformance, intrinsically safe, fullyfeatured data collector, vibration analyzer and field balancer for easy condition monitoring and troubleshooting of rotating equipment in explosive environments such as petrochemical plants, refineries, offshore oil rigs, etc. VIBXPERT EX collects field data including vibration information, bearing condition, inspection and process data and seamlessly integrates with the OMNITREND Center software platform for indepth analysis. The modular firmware structure allows you to upgrade the VIBXPERT EX from a route data collector to a fullblown troubleshooting device with advanced features such as coast down/runup measurements, event recording, ODS & modal analysis and crosschannel phase measurement.

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

The Fluke 3563 combines a highfrequency piezoelectric sensor and insightful software analytics, enabling maintenance teams to regularly monitor and analyze vibration readings for a facility’s productioncritical assets. Its smart battery management lets maintenance pros determine the data transmission rate and adapt and extend the sensor battery’s life while still getting the data required. The sensor’s LIVEAsset Portal software application includes customizable frequency band measurements, automatically generated thresholds based on asset details, trend visualization, and frequency identification graphs. These views enable users to determine which fault is causing a problem to an asset and the cause of the fault. With this analysis, users can evaluate critical nextstep actions to take. The result is extended peak operating performance and more efficient maintenance team use – delivering increased business value from maintenance operations.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

Imbalances on rotating drive shafts can be detected and eliminated with the VIBXPERT II balancer. The smart measuring principle and the powerful computing capacity enable balancing on one or two planes. Various operating modes are available for balancing, so that a perfect result is always achieved. VIBXPERT II Balancer can be upgraded to a highperformance condition monitoring device VIBXPERT II, including all operating modes for machine condition monitoring.

Request for a quoteFLUKE DEUTSCHLAND GMBH

Germany

The mobile solution for machinery health monitoring The VIBXPERT II from PRUFTECHNIK is the mobile power package for fast and reliable recording and analysis of machine condition data. After a very short measuring time, the current machine status data is shown on the color display. The maintenance expert can analyze the data on site. From the recorded machine condition data, all values can be read from the various characteristic value modes that are important for an exact machine condition analysis. The device is used directly on site at the machine, from the machine hall to the diesel generator of an oil tanker or from a bucket excavator to a hydroelectric turbine. The robust design enables both fast and complex interventions. Whether in clinically clean systems, or harsh industrial environments. VIBXPERT II sets the standard in mobile machine and plant condition monitoring.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

A unique handheld measuring device with which even untrained personnel can easily and effectively measure machine vibration on rotating machinery. Thanks to its forwardlooking measuring principle and data acquisition across three axes with the triaxial sensor, all relevant condition information is recorded with the touch of a single button. And at a measurement speed that opens up fully new dimensions. Not only is the VIBSCANNER 2 a breakthrough in terms of measurement speed and precision, but also through its robustness and its intuitive operating concept. The intuitive graphical user interface assists the employee en route in taking repeatable errorfree measurements. The device provides him/her with the exact information about the status of the measurement locations and the progress of the route.

Request for a quoteResults for

Vibrators - Import exportNumber of results

28 ProductsCompany type