- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuum systems

Results for

Vacuum systems - Import export

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our corrugated tubes and smooth tubes with connecting elements are made to customers specifications for use in low pressure duct systems. This guarantees a reliable connection and an easy and time-saving assembly and disassembly. Our product line includes a wide range of nominal sizes and line of matched accessories. Available materials/maximum operating temperature: PP/PA 110°C PA6 120°C PA12 120°C Application: Automotive, agricultural machinery and construction engines; in applications that require a small bend radius and/or dynamic stress environments, ventilation systems, connecting lines between various components for vacuum conveying systems

Request for a quote

HEAVYDRIVE GMBH

Germany

Vacuum suction systems with special plates for rough surfaces such as stone slabs, plastic panels, wooden panels, wood based boards and much more up to 6000 kg.

Request for a quote

HEAVYDRIVE GMBH

Germany

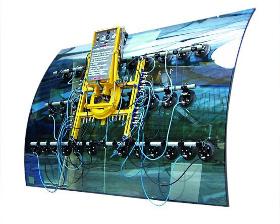

Suction systems for flat glass with up to 14000 kg capacity. For the most part variable to fit pane size.

Request for a quote

HEAVYDRIVE GMBH

Germany

Vacuum lifting devices for curved panes, concave and convex, inner and outer radius from 450 mm of up to 6000 kg for sale or hire. Also for wavy panes available.

Request for a quote

HEAVYDRIVE GMBH

Germany

Coated and vapour coated panes etc. are delicate therefore we have special non rub off suction plates for all our vacuum lifting devices ready for residue free handling. Non-marking plates leave no traces on vapour coated or mirrored panes for instance.

Request for a quote

HEAVYDRIVE GMBH

Germany

These extremely long and thin panes require special suction systems. Heavydrive® offers these suction systems in a wide range of sizes and loading capacities.

Request for a quote

HEAVYDRIVE GMBH

Germany

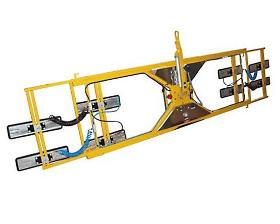

Due to its construction and suction plate form this panel suction system can be employed for both wall and roof panels It can be adjusted to fit the individual panel forms and profiles. By the deployment of extension arms even very long panels can also be safely and stabily transported.

Request for a quote

HEAVYDRIVE GMBH

Germany

Heavydrive®'s special rubber compound keeps the suction pads soft and flexible at temperatures below zero, just like snow tyres. This way, they can be used at temperatures as low as -20°C.

Request for a quote

HEAVYDRIVE GMBH

Germany

Counterweight system for suction units with a bearing load of over 1000 kg. Secure mounting under protrusions of up to 1.5 m. Can be hitched onto any construction tower or truck crane.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For removing dust prior to maintenance and repair work, e.g. on magnetic plates, reading heads, audio-visual magnetic tape recording and playback heads, phonograph pick-ups, record turntables or phonograph records For cleaning vacuum sealing surfaces, sealing rings, high-voltage insulators, sample containers etc. For vacuum systems and device groups under clean-room conditions for semiconductor production Cleaning of opto-electronic reading units for bank checks and contactless cleaning of optical devices For maintenance of automated teller machines, quartz clocks or display panels For dedusting precision mechanical parts and assemblies in office machines, copiers, fax machines etc. Advantages and benefits Excellently suited for dedusting, blowing out and blowing off dust and liquids of all kinds Dry, oil-free compressed gas leaves behind no residues Replacement for ultrapure compressed air

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product range name was changed. The old product range name was Castrol Inertox range. Inertox Heavy) Fully synthetic inert high-temperature lubricating greases Description The lubricating greases of the Castrol Braycote Inertox series (previous product name Castrol Inertox series) are chemically inert and thermally stable high-temperature greases based on high-quality, fully synthetic base oils and a thickener made of polytetrafluoroethylene. They are used for the long-term lubrication of roller and plain bearings that are subject to high thermal loads. Castrol Braycote Inertox high-temperature greases are used under aggressive environmental conditions and are resistant to inorganic and organic acids and alkalis, even in vacuum systems and clean rooms where a low evaporation rate of the base oil is required.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product range name was changed. The old product range name was Castrol Inertox range. Inertox Heavy) Fully synthetic inert high-temperature lubricating greases Description The lubricating greases of the Castrol Braycote Inertox series (previous product name Castrol Inertox series) are chemically inert and thermally stable high-temperature greases based on high-quality, fully synthetic base oils and a thickener made of polytetrafluoroethylene. They are used for the long-term lubrication of roller and plain bearings that are subject to high thermal loads. Castrol Braycote Inertox high-temperature greases are used under aggressive environmental conditions and are resistant to inorganic and organic acids and alkalis, even in vacuum systems and clean rooms where a low evaporation rate of the base oil is required.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product range name was changed. The old product range name was Castrol Inertox range. Castrol Inertox Medium) Fully synthetic inert high-temperature lubricating greases Description The lubricating greases of the Castrol Braycote Inertox series (previous product name Castrol Inertox series) are chemically inert and thermally stable high-temperature greases based on high-quality, fully synthetic base oils and a thickener made of polytetrafluoroethylene. They are used for the long-term lubrication of roller and plain bearings that are subject to high thermal loads. Castrol Braycote Inertox high-temperature greases are used under aggressive environmental conditions and are resistant to inorganic and organic acids and alkalis, even in vacuum systems and clean rooms where a low evaporation rate of the base oil is required.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product range name was changed. The old product range name was Castrol Inertox range. Castrol Inertox Medium) Fully synthetic inert high-temperature lubricating greases Description The lubricating greases of the Castrol Braycote Inertox series (previous product name Castrol Inertox series) are chemically inert and thermally stable high-temperature greases based on high-quality, fully synthetic base oils and a thickener made of polytetrafluoroethylene. They are used for the long-term lubrication of roller and plain bearings that are subject to high thermal loads. Castrol Braycote Inertox high-temperature greases are used under aggressive environmental conditions and are resistant to inorganic and organic acids and alkalis, even in vacuum systems and clean rooms where a low evaporation rate of the base oil is required.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers you a wide range of pneumatic conveying systems, taking into account the substances, the conveyor section and the feed rate. Our product range covers pneumatic thick stream conveying, thin stream conveying, dilute phase conveying as well as plug conveying in the positive pressure and vacuum range. Pipe or hose lines enable vacuum conveyance or pressure conveyance of bulk materials or liquids by means of positive pressure or vacuum. All conveying systems can be customised to meet your specific needs.

Request for a quote

SÜD-OPTIK SCHIRMER GMBH

Germany

We produce our anti reflective coatings with the most modern high vacuum coating systems both according to customer specifications and according to our own layer design, anti reflective glass, AR coating

Request for a quote

SÜD-OPTIK SCHIRMER GMBH

Germany

We produce our optical filters and other coatings with the most modern high vacuum coating systems both according to customer specifications and according to our own layer design, vacuum coating

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SÜD-OPTIK SCHIRMER GMBH

Germany

We produce our optical filters and other coatings with the most modern high vacuum coating systems both according to customer specifications and according to our own layer design, vacuum coating

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

Leak detection in the age of digitalization SONOCHEK is a digital ultrasonic testing device to detect inaudible waves and frequencies in the air or in a metal machine frame. It is primarily used to detect leaks in any industrial air and gas pressure pipes and vacuum systems. Leaks of compressed air and gas systems in particular can be very costly because more energy needs to be produced to compensate for the loss. Its detecting range reaches from 20 up to 100 kHz. These frequencies are inaudible to human ears, but SONOCHEK can detect them and make them audible and visible, while specifying the leak and evaluating the total amount of loss, all of which can be combined in a full report. An integrated camera and microphone enable the engineer to comment on his findings and refine the final report.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

150 - 3000 CFM The pre-engineered VectraPaks are a versatile and readily available system for any industrial vacuum need. The Vectrapak comes with the accessories already mounted and piped for ease of installation. They are available from 150 to 3000 ACFM, suitable for operation to 29" HgV, and are available in both iron and stainless steel construction.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

For over half a century, NASH systems have been the products of choice for air removal systems in steam cycle power plants throughout the world. By reducing the energy loss due to air leakage into the condenser, our vacuum systems save millions of dollars worth of energy every day.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

These Duplex Vacuum Systems consist of an air ejector, two Vectra XL350 liquid ring vacuum pumps, interconnecting piping and related instrumentation. The vacuum pumps and ejector are manufactured in Aluminum Bronze and the piping interconnections are manufactured in Fiberglass Reinforced Epoxy. These special materials of construction ensure the usual Nash reliability even in the harsh conditions of offshore production.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Priming Valves for Liquid Ring Vacuum Pumps Gardner Denver Nash priming valves were designed specifically to be used in Nash vacuum pump priming systems. They are extremely simple, dependable and durable. It has been proven in successful service for nearly fifty years. A Nash vacuum system is often used to prime one or more centrifugal pumps located above the free liquid levels of their suction sources. Vacuum draws liquid up until it fills each pump's suction line and floods its volute. This condition can be established before the pump is started up, so that it is always primed and ready to begin pumping. A Nash vacuum system is often used to prime one or more centrifugal pumps located above the free liquid levels of their suction sources. Vacuum draws liquid up until it fills each pump's suction line and floods its volute. This condition can be established before the pump is started up, so that it is always primed and ready to begin pumping

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Chemical Process Industry / Oil & Gas Industry Our vacuum and compressor systems maximize output and efficiency while minimizing maintenance and environmental pollution. Made of stainless steel and other sophisticated materials, they handle explosive and corrosive gases safely and efficiently. Pulp & Paper Industry Providing vacuum pumps and related equipment to the pulp & paper industry is a Gardner Denver Nash specialty. We are well known as an industry leader in engineered vacuum systems and water removal for paper machines. NASH vacuum pumps are used throughout the forming and press sections of a paper machine. Power Industry For over half a century, NASH has been the manufacturer of choice for air removal systems in steam cycle power generation plants throughout the world. NASH condenser exhauster packages efficiently remove inward air leakage from the condenser and improve the efficiency of the turbine under all operating conditions. Other Industries For more than 100 years, Nash has engineered liquid ring vacuum pumps, liquid ring compressors and engineered systems for the toughest applications. Our systems operate dependably for decades in filter applications, refineries, the sugar industry, in the food processing industry, mining and many more applications.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

100 - 3600 CFM / 170 to 6,100 m³/h The NASH SC vacuum pump and compressor, which replaced the popular NASH CL pump in the 1980's, is still being manufactured at Gardner Denver Nash. The SC pump, more flexible and simpler to install and easy to maintain, made it a very reliable pump to be used in many applications. SC pumps are found in applications including: autoclaves, chucking, container filling, labeling and forming, cooking, deaerating, deodorizing food and fats, drying, evaporating, eviscerating, exhausting, extruder venting, fiber setting, filtering, forming, gas stripping, laboratory central vacuum systems, medical and dental vacuum draining, molding, pickup and conveying, priming, slot extraction, and solvent recovery. All SC models are still available from Gardner Denver Nash, the original designer and manufacturer. Whether you have an existing SC pump running in your plant that is in need of service, repair, or replacement with a new or remanufactured duplicate SC pump, Gardner Denver Nash is there for all of the above.

Request for a quote

FRIEDENSTAB KUNSTSTOFFTECHNIK GMBH

Germany

With a modern machine park, we are able to produce injection molded parts up to approx. 400 grams. The materials used for this are e.g. PS, ABS, PP and PE, but also technical plastics. With a modern machine park, we are able to produce injection molded parts up to approx. 400 grams. The materials used for this are e.g. PS, ABS, PP and PE, but also technical plastics such as PA6, POM or IXEF are often used. Brief overview ARBURG injection molding machines Component weight: approx. 2 - 400 grams Closing forces: 50 - 220 tons Hybrid components (insert / outsert technology) Removal robots / vacuum gripping systems Automation around the injection molding process Central material handling system Material preparation Material drying

Request for a quoteResults for

Vacuum systems - Import exportNumber of results

27 Products