- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- systems engineering

Results for

Systems engineering - Import export

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Chemical Process Industry / Oil & Gas Industry Our vacuum and compressor systems maximize output and efficiency while minimizing maintenance and environmental pollution. Made of stainless steel and other sophisticated materials, they handle explosive and corrosive gases safely and efficiently. Pulp & Paper Industry Providing vacuum pumps and related equipment to the pulp & paper industry is a Gardner Denver Nash specialty. We are well known as an industry leader in engineered vacuum systems and water removal for paper machines. NASH vacuum pumps are used throughout the forming and press sections of a paper machine. Power Industry For over half a century, NASH has been the manufacturer of choice for air removal systems in steam cycle power generation plants throughout the world. NASH condenser exhauster packages efficiently remove inward air leakage from the condenser and improve the efficiency of the turbine under all operating conditions. Other Industries For more than 100 years, Nash has engineered liquid ring vacuum pumps, liquid ring compressors and engineered systems for the toughest applications. Our systems operate dependably for decades in filter applications, refineries, the sugar industry, in the food processing industry, mining and many more applications.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

The new NASH XT Systems use the Nash pump advantages within a water-saving, self-contained system. Their capacity range is 200-1300 CFM (340-2210 m3/h). Designed for use in clean applications, such as medical centers, labs, paper converting, semiconductor applications, dairy and more, XT Systems give you the benefits of a liquid ring vacuum pump without the problem of providing constant seal liquid.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

The NASH Vectra XL series of liquid ring pumps was designed to operate as both a vacuum pump and a compressor with a maximum pressure differential of 30 psig. This allows a negative pressure to be applied to the wells and can: assist in the production of low pressure natural gas and/or remove low pressure gas to aid in the production of oil. The discharge gas can be sent to a high pressure reciprocating compressor for pipeline transport. The systems are built on a platform that can be moved from well to well as needed.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

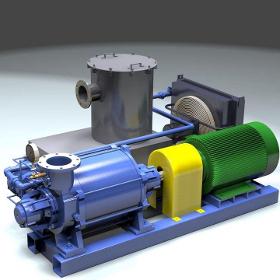

150 - 3000 CFM The pre-engineered VectraPaks are a versatile and readily available system for any industrial vacuum need. The Vectrapak comes with the accessories already mounted and piped for ease of installation. They are available from 150 to 3000 ACFM, suitable for operation to 29" HgV, and are available in both iron and stainless steel construction.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

40-150 CFM Pre-engineered SX Packages are a versatile and readily available system for any industrial vacuum need. The SX Packages come as either once-through or recirculated packages with the accessories already mounted and piped for ease of installation. Built with Nash patented gas scavenging, to increase high vacuum performance, they are available from 40 to 150 ACFM (70-250 m3/hr), suitable for operation to 29" HgV (31 mbar abs), and are available in cast iron construction.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

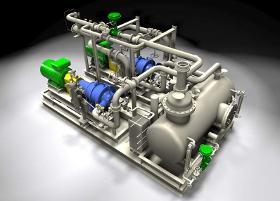

These Duplex Vacuum Systems consist of an air ejector, two Vectra XL350 liquid ring vacuum pumps, interconnecting piping and related instrumentation. The vacuum pumps and ejector are manufactured in Aluminum Bronze and the piping interconnections are manufactured in Fiberglass Reinforced Epoxy. These special materials of construction ensure the usual Nash reliability even in the harsh conditions of offshore production.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

0-29 in HgV (to 33 mbar abs) If you thought you couldn't afford the water costs associated with operating a liquid ring pump…think again. One of the wonderful features of the liquid ring pump is that it can be operated with a multitude of different fluids. A self-contained oil sealed system has a number of benefits over a traditional water sealed system: It eliminates water usage and disposal costs; it allows you to install it in remote locations where water may not be available; it allows you to attain higher vacuum levels than with water; it can prevent the condensing or dissolving of a process gas; it permits anhydrous processing with a liquid ring pump. Self contained system complete with off of the components for your basic operating needs. Standard components include: pump, TEFC motor, coupling or v-belt drive, drive guard, separator with oil mist eliminator, air cooled heat exchanger, recirculated seal line controls and high temperature alarm switch. Options include: inlet isolation valve, inlet check valve, vacuum relief valve, inlet filter, control panel and system skid plate. An oil sealed liquid ring system is more tolerant of carryover and wear, and it provides quiet operation. The oil is not required for lubrication which means it can operate at extremely long intervals between oil changes, easily going more than 10,000 hours with no down time. Aside from a periodic oil and filter change, the system can run for years with no scheduled maintenance. If your process requires very deep vacuum, Gardner Denver Nash has the solution. Using a two-stage liquid ring pump in an oil sealed system, vacuum levels lower than 10 Torr (29.6" HgV) can be attained.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

All components pass a quality inspection before being used. Many different methods and procedures are used here (e.g. PMI 0 positive material inspection, crack detection). Our scope of machining reaches from chipping/metal cutting to sandblasting (using granule materials) to welding, assembling and painting. We handle many different metallic and nonmetallic materials as steel, stainless steel, duplex materials, titanium, plastic material We give a big importance to welding: Nash employees are certified according to ASME 9 and therefore qualified to manufacture pressure vessels and piping according to Pressure Equipment Directive (DIN EN 3834) and ASME Standards (31.3). Our systems are painted according to customer specification. We work with all wet paints and 2K paints. Anti-corrosion-coatings up to category C5M are possible. Of course, we meet all the other specifications, e.g. regarding coating thickness, as well. The electrical engineering is also done in the Nash location, from design to cabling. After the completion, the system undergoes a pressure test. Furthermore there is an option to do a complete function test to verify the performance data. Nash is certified according to ISO 9001 and ISO 14001.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Steam Ejectors & Liquid Ring Vacuum Pumps Engineered for optimum efficiency, Nash Hybrid Systems now offer a 15% reduction in steam consumption. This was achieved through extensive R&D efforts, resulting in innovative design improvements. Nash has designed and manufactured hybrid systems since 1979, and our hybrid systems are recognized worldwide for reliable performance and low greenhouse gas emissions. As the new standard for Nash hybrid designs, these systems maintain traditional benefits, while offering accelerated payback through increased energy savings, condensers designed per HTRI specifications and a faster response time through regional sourcing. Nash is the only company to manufacture both the pumps and ejectors that go into a hybrid system, and offers a complete system warranty. All Nash hybrid systems are backed by global aftermarket support, decades of engineering expertise, and a proven history of reliable, dependable installations. Existing all ejector systems can be upgraded to more efficient hybrid systems by replacing or modifying stages. Nash engineers can evaluate your specific systems and recommend a custom hybrid design that will optimize your energy savings. Through reduced operating costs, upgraded systems can offer a payback of 2 years or less. Nash hybrid systems are used in industries and applications where deep vacuum is required and system reliability is critical. In operations where efficiency is key, emissions are a concern, or if there is a scarcity of steam in the plant, Nash hybrid systems are the optimal solution for efficiency.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Gardner Denver Nash’s HP and NAB compressors are the ideal choice for recovering fuel gas and condensing valuable hydrocarbons, making more money for the refinery. When reviewing the total life cycle cost of a flare gas compressor system, the NASH liquid ring system provides more value and better reliability than any other technology, hands down. Liquid ring compressors run cool and they clean the gas as they compress it–eliminating the need for downstream aftercondensers and scrubbers. The result is a simpler, more reliable system.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

From the first planning to shipment, every project is accompanied by one constant contact person. Depending on industry, process and specification, the best material (steel, stainless steel, duplex materials, titanium, plastic material) is chosen. There is a big importance to consider and meet the different standards and rules. Whether its DIN, ISO, ATEX, GOST ASME or PED (pressure equipment directive) - Nash engineers know all these general frameworks and restrictions. Our team of engineers finds the best solution to realize the customer's requirements.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

For over half a century, NASH systems have been the products of choice for air removal systems in steam cycle power plants throughout the world. By reducing the energy loss due to air leakage into the condenser, our vacuum systems save millions of dollars worth of energy every day.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers the complete range of conveying systems, storage systems and handling systems in mechanical engineering. Our plants and systems can be integrated into your own conveyor line or designed as completely automated systems. External plant components can also be integrated into our superordinate control system. Our plants and systems are mainly used for bagging or bottling or batch loading systems. Application of conveying, storage and handling systems: Dosing and application of liquids in the plant process Dosing and mixing of powders, fibres and liquids Bagging and bottling systems integrated into a production line Silo systems and tank systems with conveying paths and mixing systems Pipe shell plants

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The adjustable sliding gate orifice type 8090 in reinforced version is suitable for precise and continuous adjustment of a defined flow. It can be adjusted and secured manually in the installed state during operation. Among other things, the orifice facilitates the hydraulic adjustment of cooling systems, e.g. when commissioning large engines in CHPs and on ships.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The adjustable sliding gate orifice type 8090 is suitable for precise and continuous adjustment of a defined flow. It can be adjusted and secured manually in the installed state during operation. Among other things, the orifice facilitates the hydraulic adjustment of cooling systems, e.g. when commissioning large engines in CHPs and on ships.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Antifreeze for motorcycles and scooters Description Castrol Motorcycle Coolant is a ready-to-use, premixed antifreeze based on ethylene glycol. It ensures frost protection down to -25 °C and should be changed every 2 years or according to the manufacturer's instructions. Suitable for all aluminum engines. Caution: Not suitable for use in magnesium alloy engines. Advantages - Optimal corrosion protection in the cooling system, thereby extending engine life - Excellent cooling and heat transfer properties - Protection of all cooling system components - Compatible with motorcycle paintwork - Offers frost protection down to -25° Celsius Specifications Based on coolant concentrate conforming to: ASTM D3306 (I) BS 6580:2010

Request for a quote

MICRO-EPSILON

Germany

Rotation speed sensors are used to monitor, regulate and control mechanical drive systems and play a major role when it comes to protecting elements of a rotational system (e.g., in the engine, drive) from mechanical overload. Micro-Epsilon offers two sensor systems for rotation speed measurement. The capaNCDT CST6110 is a universal rotation speed sensor for counting tasks and rotation speed applications of any type. Moreover, the turboSPEED DZ140 measuring system is specifically designed for the detection of turbocharger rotation speeds.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

The range of external vibrators from Knauer Engineering includes normal frequency, high frequency and oscillating vibrators in various executions for applications in the construction and concrete industry as well as in other industries. Besides the proven vibrator system of Losenhausen, Knauer Engineering also offers now a considerably vibrator program for multi-purpose working areas. Applications are used in Construction industry, Industry of building materials, Mining-, Chemical-, Packaging and food industry, mechanical engineering as well as quality inspection and quality assurance.

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

Viscous Fan Drives and Controllers VMaster Di is an economically priced, reliable system that provides variable-speed fan control specifically tailored to your engine cooling requirements. J1939 compatible, VMaster Di is a plug-and-play system that keeps your engine at optimal operating temperature while reducing operating noise, saving fuel and increasing performance. The VMaster Di system also increases available horsepower for auxiliary components. This maintenance-free system is engineered to turn any 20-inch [508 mm] to 44-inch [1118 mm] plastic, metal or composite fans. Benefits - Reduces noise and saves fuel - Optimized cooling under all conditions - Better performance - Increased available horsepower for auxiliary components - More economical and safer than hydraulic systems Features - Variable-speed control - Customized algorithms for specific requirements - J1939 compatible - 12V/24V - Integral diagnostics - 70 percent fan speed override to meet the European noise directive - 105C temperature rating - Maintenance-free - Compatible with a wide range of fan sizes Applications - Skid steers - Truck cranes - Cement trucks - Refuse trucks - Medium-duty day cab class 7 – 4 trucks - Power generators - Other on- and off-highway Related Products - Stratis Viscous Fan Drives - Stratis Di Viscous Fan Drives and Controllers - VMaster® Air-Sensing Fan Drives - VMaster Directly Controlled Fan Drives - WindMaster Fans Links - Order or View Literature - On-line Catalog

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

VMaster® Viscous Directly Controlled Fan Drives Now there's a viscous fan drive that responds to changing cooling requirements. Based on pulse-width-modulation (PWM) signals from the engine management system, VMaster viscous directly controlled fan drive adjusts its output to provide just the degree of cooling needed. Benefits - Rapid responsiveness - Optimum idling speed - Greater torque transmission - Modular and can be used with fans from other manufacturers - Endurance tested Features - Improved outer tube design - Simplified mounting - Integrated speed monitoring system applications - Compatible with engine management systems Applications - Heavy-duty trucks - Medium-duty trucks - Light-duty trucks - Automotive - Off-highway equipment Related Products - MagForce Electromagnetic Fan Drives - VMaster Viscous Air-Sensing Fan Drives - WindMaster Fans - WindMaster Ring Fans Links - Order or View Literature

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

Stratis Di Viscous Fan Drives and Controllers Stratis Di is an economically priced, reliable system that provides variable-speed fan control specifically tailored to your engine cooling requirements. J1939 compatible, Stratis Di is a plug-and-play system that keeps your engine at optimal operating temperature while reducing operating noise, saving fuel and increasing performance. The Stratis Di system also increases available horsepower for auxiliary components. This maintenance-free system is engineered to turn any 20-inch [508 mm] to 44-inch [1118 mm] plastic, metal or composite fans. Benefits - Reduces noise and saves fuel - Optimized cooling under all conditions - Better performance - Increased available horsepower for auxiliary components - More economical and safer than hydraulic systems Features - Variable-speed control - Customized algorithms for specific requirements - J1939 compatible - 12V/24V - Integral diagnostics - 70 percent fan speed override to meet the European noise directive - 105C temperature rating - Maintenance-free - Compatible with a wide range of fan sizes Applications - Skid steers - Truck cranes - Cement trucks - Refuse trucks - Medium-duty day cab class 7 – 4 trucks - Power generators - Other on- and off-highway Related Products - Stratis Viscous Fan Drives - VMaster® Air-Sensing Fan Drives - VMaster Directly Controlled Fan Drives - VMaster Di Viscous Fan Drives and Controllers - WindMaster Fans Links - Order or View Literature - On-line Catalog

Request for a quote

NORIS GROUP GMBH

Germany

Compact and robust safety system for engines Safety system for engine emergency shut-down Compact and robust design for applications directly on engines Large number of preprogrammed engine types All inputs are monitored for wire breaks All connections are plug-in for easy installation Ideal for use in shipbuilding thanks to approvals from classification societies The safety system N3000-SAP has been developed for electrically monitoring the basic operating parameters of a combustion engine. It is the central unit for triggering an emergency shut-down of the engine to avoid damage. Thanks to its compact and robust design, it is particularly suitable for use on ships, directly on combustion engines. Signal processing with the safety system is purely digital. Together with fast, crystal-accurate speed acquisition, it ensures maximum safety and system reliability.

Request for a quote

NORIS GROUP GMBH

Germany

The emergency order telegraph system allows the bridge and engine room to communicate with one another quickly and reliably in case of an emergency. An order is transmitted from the bridge to the engine room at the touch of a button, where it is then signalled visually and acoustically on one or more telegraphs. The staff in the engine room need to acknowledge the order to make the visual and acoustic alarm stop. Up to 12 telegraphs can be integrated in one system. Each telegraph is equipped with 11 illuminated order buttons and an integrated buzzer. Furthermore, other functions, such as changing over between two telegraph systems, "wrong-way alarm" or the activation of external alarm indicators, can be integrated, too. The emergency order telegraph system is flexible and scalable, meaning it is suitable for small applications with just two devices (e.g. bridge and in engine room) right up to large installations with several systems (multiple bridges and engine rooms).

Request for a quote

NORIS GROUP GMBH

Germany

The N3500 (NORIMOS 3500) is our cost-efficient alarm, monitoring and control system for engines and auxiliary systems. The system is based on two central, redundant PC master stations. They collect and monitor the measurement data from the connected I/O modules. With up to 9,000 I/Os, a matching alarm extension system for accommodation and a monitoring display for the bridge, the system can be easily extended and adapted to any application. The N3500 is based on robust components and can be used flexibly: from simple data acquisition systems up to complex alarm and monitoring systems with integrated control functions for pumps, valves and fans. The system is approved by all conventional shipbuilding classification societies (ABS, BV, CCS, DNV-GL) and thus, is the ideal companion for all aspects of the monitoring and control of shipboard propulsion systems.

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our ducts and corrugated tubes for engine air intake can feature flexible sections, smooth sections and matching connections to meet customers specifications. This is a reliable way to connect a corrugated tube to the connecting cuff and allows for time-saving assembly. The advantages are obvious: Weight can be reduced, and great flexibility with high flow quantity and high strength in the cuff section are guaranteed. Available materials/maximum operating temperature: PP 100°C PA6 120°C PA12 120°C Application: Automotive, agricultural machinery and construction engines, in applications that require small bend radii and/or dynamic stress environments, connecting lines between various components, engine air intake

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Push Pull chains transmit compressive and tensile forces – usually without additional guidesAnti-backbend chains or push pull chains are flexible only on one side for pushing loads and for bridging gaps without guides. Custom anti-backbend chains or push push chains developed by iwis are used all over the world in applications such as medical technology, conveyor systems, building services engineering or machine tools.

Request for a quote

STOBA SONDERMASCHINEN GMBH KG

Germany

Many years of expertise in system engineering for industrial cleaning technology Suitable for processes such as precleaning, postcleaning, conserving and drying Mobile and stationary multichamber cleaning systems for aqueous cleaning media Standardized or individual solutions tailored to the needs of the customer Manual or fully automated concepts Subsequently extendable and expandable Low operating costs with high availability Can be combined with stoba ECM/PECM systems Controller Siemens

Request for a quoteResults for

Systems engineering - Import exportNumber of results

28 ProductsCategory

- Pressure regulators (2)

- Lubricants, industrial (1)

- Mechanical engineering - custom work (1)

- Automation - systems and equipment (1)

- Electronics - ships (1)

- Foundry machines - centrifugal (1)

- Goods handling systems, continuous (1)

- Hoses, pipes and tubes - plastic (1)

- Mechanical transmission systems and components (1)

- Sensors (1)

- Vibrators, industrial - installations (1)

- maritime security system (1)