- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spirals

Results for

Spirals - Import export

BILLI DICHTUNGSTECHNIK GMBH

Germany

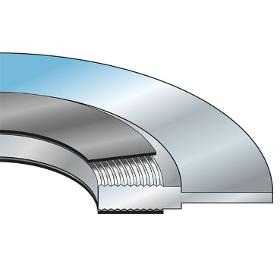

In order to be able to meet the individual requirements of our customers, we offer various types of spiral wound gaskets: For example, you can choose between standard versions with a smooth surface and various special models. All articles are based on a stainless steel strip and high-quality filling materials such as graphite and PTFE, which underlines the excellent quality standard. The spiral wound gaskets of billi are characterized by a constant elasticity during hot-cold cycles. Classical applications in the chemical industry include all types of gas lines, directional valves and pumps. Furthermore, spiral wound gaskets are the optimal solutions for pressure vessel openings in steam systems as well as low and high pressure in nuclear power plants. For the best possible functionality of spiral wound gaskets, the careful considered choice of model is of central importance: the versions with centering ring, for example, assures an ideal fit between the bolts.

Request for a quote

SPIROL

Germany

SPIROL’s heavy duty & fatigue resistant Coiled Spring Pins are available in diameters ranging from 1.5mm (.062") up to 20mm (.750"). Standard materials include high carbon steel, 302/304 nickel (austenitic) stainless steel, and 420 chrome (martensitic) stainless steel. Diameters larger than 12mm (.500") are available in 6150 alloy steel. SPIROL invented the Coiled Spring Pin in 1948. Coiled Pins are available in light duty, standard duty and heavy duty to match the required strength and flexibility for each application. A pin too strong for the applied load will not flex and may damage the hole. A pin that is too flexible may fatigue prematurely within the assembly. The Coiled Pin with the optimal balance of strength, flexibility and diameter will result in the prolonged useful life of the assembly.

Request for a quote

WOLF BUTTERBACK KG

Germany

Delicious fried pastries in fine variations

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

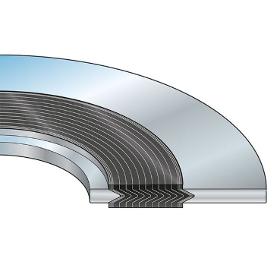

D 7 ProCor Camprofile Gasket, Rip profiled metal base covered with graphite or PTFE, optional with or without center ring(s). 1] pay attention to the temperature limit of PTFE Characteristics For flange connections in high pressure piping and in fittings Extremely low leakage values with PTFE inlay. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance up to 550 °C with graphite inlay Technical parameters Covermaterial PTFE Temperature range: -200... +260 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 Covermaterial Graphit Temperature range: -200... +500 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 1] pay attention to the temperature limit of PTFE Main application For all flanges inside the main traction line High level of temperature and pressure resistance Suitable for Power plants Petrochemical...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Spiral wound gasket made of crimped metal tape with sealing wraps of non asbestos gasket material. Optional: inner and/or outer metal ring. Characteristics For flange connections in high pressure pipe line construction and fittings Extremely low leakage with PTFE spiral. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance to 550 °C with graphite spiral Media resistance: pH 0 - 14 Max. pressure load: p = 400 bar Temperature range: t = -200 to +550 °C Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C Pressure: p = 400 bar Main application High temperature and high pressure flanges Piping Pressure vessels Heat exchangers Fittings Suitable for Power plants Petrochemical plants Chemical industry Material Centerring ring OD: Carbon Steel galvanized Spiral: 316L Centerring ring ID: Carbon Steel galvanized Other material combinations on request Product Types SF 11 Spiral wound gasket without any center ring for flanges with tongue and groove connection SF...

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

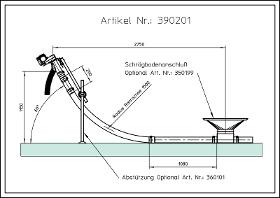

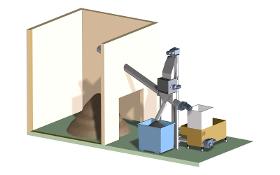

For stationary hackers, we offer flexible and rigid discharging systems. With both systems we assume the material directly in the hacker and convey it to the desired discharge point. The transport takes place without any pressure. Due to our compact design you do not need ground indentations. Depending on the intended use, our rigid or flexible spirals will be fitted in. These systems could be combined with modules like magnetic separators or interim outlets.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Are you looking to transport pellets inexpensively and save energy? The flexible spiral conveyors from the Bavarian manufacturer Steiner Spiralen (Kirchdorf am Inn) can meet your needs under the most varied conditions. Vertical or horizontal transport of wood pellets can be easily achieved just as well as overcoming large differences in elevation and long transport routes. Steiner Spiralen pellet conveyor systems guarantee you efficient and worry-free transport of pellets. When transporting pellets is the issue, our customers have trusted our conveyor systems for 30 years.

Request for a quote

STEINER GMBH & CO. KG

Germany

Impurities of your transported goods are often problematic and can be also guilty of disorders. They may even cause damage. But do not desperate! Our tried and tested magnetic separators will help you. These magnetic separators take care to filter out foreign substances. Simply and reliably.

Request for a quote

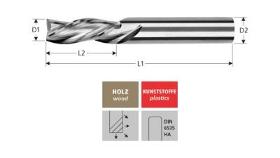

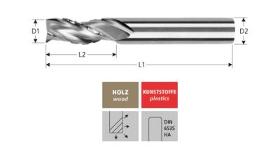

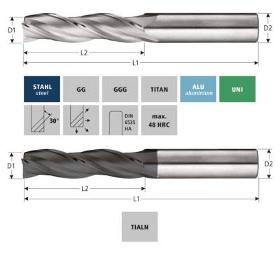

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

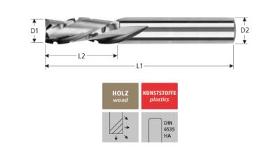

fine-grain solid carbide finishing end mill: with triple flute, right-hand cutting, downcut spiral, shank without clamping surface DIN 6535-HA

Request for a quote

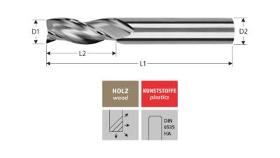

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide finishing end mill: with triple flute, right-hand cutting, upcut spiral, shank without clamping surface DIN 6535-HA

Request for a quote

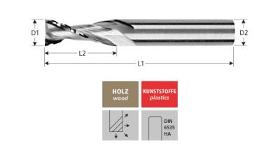

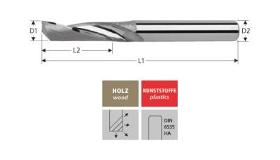

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide roughing end mill: with double flute, right-hand cutting, upcut spiral, shank without clamping surface DIN 6535-HA

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

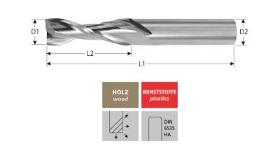

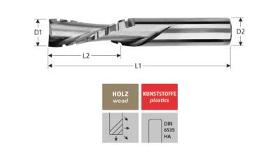

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide finishing end mill: with double flute, right-hand cutting, upcut spiral, shank without clamping surface DIN 6535-HA

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

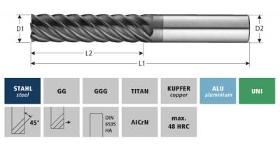

fine-grain solid carbide finishing end mill: with 4-8 flutes

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide end mill: with triple flute, with toric cut

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

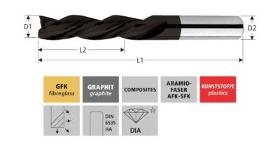

fine-grain solid carbide triple flute end mill: with triple flute, right-hand cutting, downcut spiral, shank without clamping surface DIN 6535-HA, suitable for fibreglass-reinforced plastics and graphit, with diamond-coating

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide roughing end mill: with triple flute, right-hand cutting, downcut spiral, shank without clamping surface DIN 6535-HA

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide roughing end mill: with triple flute, right-hand cutting, upcut spiral, shank without clamping surface DIN 6535-HA

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide single flute end mill: with single flute, right-hand cutting, upcut spiral, shank without clamping surface DIN 6535-HA

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide roughing end mill: with double flute, right-hand cutting, downcut spiral, shank without clamping surface DIN 6535-HA

Request for a quote

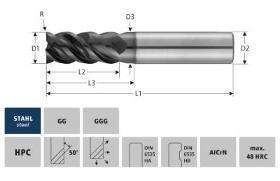

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide hpc end mill: with 3-4 flutes, with toric cut

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

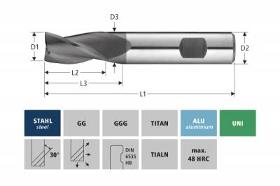

fine-grain solid carbide end mill: with triple flute, without toric cut, 30°-spiral

Request for a quoteResults for

Spirals - Import exportNumber of results

28 ProductsCompany type