- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pins

Results for

Pins - Import export

SPIROL

Germany

You can rely on SPIROL to be a design partner to help solve unique problems. Because we supply numerous customers with similar products in similar industries, we are able to meet most needs with our standard products at no additional cost. When the solution falls outside the normal requirements, we have the expertise and engineering personnel to solve those problems. By working with you at the design stage, we will develop a solution that lowers your overall product cost, improves product quality, increases the robustness of your manufacturing process, and gets you to market faster.

Request for a quote

SPIROL

Germany

Series RH600 Twist-Lok™ Pins replace costly screw machined pins and eliminate problematic installation of screws and rivets. The helical knurl minimises stress during installation by rotating as it engages the hinge. Corrosion-resistant material and a rounded burr-free head improve installed appearance. Axial and radial forces induced in the hinge eliminate the tendency for the pin to creep and maintain hinge tension.

Request for a quote

SPIROL

Germany

SPIROL's Series LP500 Latch Pins for Plastics are designed with a barb located under the head with a barb length equal to the width of the outermost section of the assembly. The remaining length of the LP500 Latch Pin is smooth without any other retention features. This allows the LP500 Latch Pin for Plastic to easily align and freely install through all of the holes with a plastic assembly until the barb makes contact with the final hole to securely lock the pin in place. Once fully installed, the handle will pivot freely around the non-barbed end of the stationary pin. The head prevents the LP500 Latch Pin from being over-installed, and enables the pin to be mechanically oriented for automatic installation. Manufactured from lightweight, lead free aluminium, SPIROL's LP500 Latch Pins for Plastics are available in three standard diameters: 3mm, 4mm and 5mm.

Request for a quote

SPIROL

Germany

SPIROL designs and manufactures specific types of Solid Pins to meet the performance and assembly requirements of common niche applications. These Solid Pins are variations of our standard product either manufactured from specific material, have a specific finish or undergo specific processing to meet performance, corrosion, compatibility and assembly requirements for the specific application. These pre-designed application-specific series of Solid Pins help companies shorten the design cycle to confidently launch their product quickly to the market with a pinning solution that has been tested and proven within their assembly.

Request for a quote

SPIROL

Germany

SPIROL's FH400 Headed Barbed Pin has a series of barbs extending down the entire length of the pin. Headed Barbed Pins are a great replacement for self-tapping screws in plastic assemblies as Barbed Pins are installed into standard moulded (or drilled) holes, they install much faster than screws, and they eliminate issues associated with cross-threaded or skewing during installation. Unlike screws that resist back-out (or loosening) by being tightened to a preset torque, Barbed Pins are retained by the plastic backfilling over the aggressively-designed barbs. The head provides a positive stop and is also used to retain a thin component to a thicker component within an assembly. SPIROL's FH400 Headed Barbed Pins are available in metric diameters ranging from Ø2mm to Ø6mm and inch diameters ranging from Ø.078" (5/64) to Ø.250" (1/4) in low carbon steel and austenitic stainless steel.

Request for a quote

SPIROL

Germany

SPIROL's BP100 Press-N-Lok™ Pin has opposing barbs on each end of the pin and is designed to permanently retain two plastic components to each other such as two halves of a plastic enclosure. Press-N-Lok™ Pins are installed in two stages: First, press the pins into one half of the plastic housing. Next, align the other half of the housing with the exposed pins and press into place. During installation, the plastic will backfill into the area around the barbs resulting in maximum resistance to axial force. SPIROL's Press-N-Lok™ Pins are manufactured from lightweight, lead free aluminium as a standard, and available to order in austenitic stainless steel. BP100 Press-N-Lok™ Pins are available in diameters ranging from 2mm to 4mm.

Request for a quote

SPIROL

Germany

SPIROL's Barbed Pins were created specifically for use in flexible plastics where optimum resistance to axial force is desired. The raised barbs are angled backwards, opposite the direction of insertion. After installation, the plastic will backfill into the area around the barbs resulting in maximum retention. Barbed Pins are ideal for applications requiring high pull-out (tensile) strength, and to prevent disassembly (i.e. tamperproof ). Barbs are not appropriate for brittle plastics or those containing high percentages of fillers. As barbs are a radial feature, they do not resist rotation of two components relative to one another. For this requirement, a straight or helical knurl should be used. All Barbed Pins are provided with a generous pilot to facilitate alignment with the hole and ease installation.

Request for a quote

SPIROL

Germany

SPIROL's FH300 Headed Helical Knurled Pin has the same body style as the KP300 Helical Knurled Pin, with the addition of a head. A Headed Pin is typically used to provide a positive stop or to retain a thin component to a thicker component within an assembly. FH300 Headed Helical Knurled Pins have a flat head, however they are available to order with a round head (RH300) to meet specific application requirements. Similar to the SPIROL Series KP300 Helical Knurled Pin offering, SPIROL's FH300 Headed Helical Knurled Pins are available in metric diameters ranging from Ø2mm to Ø6mm and inch diameters ranging from Ø.078" (5/64) to Ø.250" (1/4) in low carbon steel and austenitic stainless steel.

Request for a quote

SPIROL

Germany

SPIROL's FH200 Headed Straight Knurled Pin has the same body style as the KP200 Straight Knurled Pin, with the addition of a head. A Headed Pin is typically used to provide a positive stop or to retain a thin component to a thicker component within an assembly. FH200 Headed Straight Knurled Pins have a flat head, however they are available to order with a round head (RH200) to meet specific application requirements. Similar to the SPIROL Series KP200 Straight Knurled Pin offering, SPIROL's Series FH200 Headed Straight Knurled Pins are available in metric diameters ranging from Ø2.5mm to Ø6mm and inch diameters ranging from Ø.094" (3/32) to Ø.250" (1/4) in low carbon steel and austenitic stainless steel.

Request for a quote

SPIROL

Germany

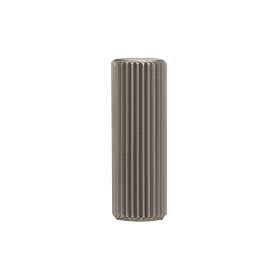

SPIROL's KP300 Helical Knurled Pins have helical knurls that span the full length of the pin. The 30° helical knurls cause the pin to rotate during installation into the hole. Helical Knurled Pins offer higher insertion and retention than Straight Knurled Pins. However, KP300 Helical Knurled Pins are not typically recommended when the pin will be subjected to rotational forces as the helical knurl will cause the pin to either "unscrew" itself from the hole or further imbed itself into the hole. KP300 Helical Knurled Pins are available in metric diameters ranging from 2mm to 6mm and in inch diameters ranging from .078" (5/64) to .250" (1/4) in low carbon steel and austenitic stainless steel.

Request for a quote

SPIROL

Germany

SPIROL's KP200 Straight Knurled Pins have straight knurls that span the full length of the pin. Straight Knurled Pins are commonly used in applications where the pin is subjected to rotational forces to transmit torque as well as to resist rotational movement of a mating component. KP200 Straight Knurled Pins are available in metric diameters ranging from 2.5mm to 6mm and in inch diameters ranging from .094" (3/32) to .250" (1/4) in low carbon steel and austenitic stainless steel.

Request for a quote

SPIROL

Germany

SPIROL's Knurled Pins are manufactured with two different knurl types: straight knurls and helical knurls. Unlike a Straight Pin, where retention is provided by the uniform interference between the pin and hole, Knurled Pins are designed to cut into the host. The displacement of the host material into the valleys of the knurls yields more frictional contact area between the Knurled Pin and hole; thus resulting in higher retention. Solid Pins with retention features such as knurls and barbs allow for wider hole tolerances than Solid Pins without retention features (i.e. Straight Pins).

Request for a quote

SPIROL

Germany

SPIROL's FH100 Headed Straight Pin has the same body style as the DP100 Straight Pin, with the addition of a head. A Headed Pin is typically used to provide a positive stop or to retain a thin component to a thicker component within an assembly. FH100 Headed Straight Pins have a flat head, however they are available to order with a round head (RH100) to meet specific application requirements. Similar to the SPIROL Series DP100 Straight Pin offering, SPIROL's Series FH100 Headed Straight Pin is available in metric diameters ranging from Ø2mm to Ø6mm and inch diameters ranging from Ø.078" (5/64) to Ø.250" (1/4).

Request for a quote

SPIROL

Germany

SPIROL's DP100 Straight Pins have smooth outer diameters with no retention features such as knurls or barbs. When used as a press-fit pin, the DP100 Straight Pin is pressed into a hole sized slightly smaller than the diameter of the pin. SPIROL's DP100 Straight Pins are suitable for press fit in host materials that can withstand compression in the order of 0.05mm – 0.08mm (.002” – .003”). The actual recommended hole size for a press-fit depends on the actual host material. It is for this reason that SPIROL Engineering should be consulted for the recommended hole size when DP100 Straight Pins are intended to be press-fit into an assembly. Straight Pins are a great option for applications that do not require the tight tolerances of Machined Solid Pins or Ground Solid Dowels. SPIROL Series DP100 Straight Pin consists of metric diameters ranging from Ø2mm to Ø6mm and inch diameters ranging from Ø.078" (5/64) to Ø.250" (1/4).

Request for a quote

SPIROL

Germany

Offered with or without a head, Straight Pins are distinguished by their uniformity. The chamfered ends are more consistent than tumbled edges—making installation with automatic assembly equipment more reliable. Straight Pins are retained by compressing the host, not the inflexible solid pin. They are suitable for use in plastics for press-fit applications limited to those cases where the host material can withstand compression in the order of 0.05mm – 0.08mm (.002” – .003”). Straight Pins are often used to replace Ground Dowels in applications that do not require the tight tolerances of a Ground Dowel.

Request for a quote

SPIROL

Germany

This exceptionally versatile tool is ideally suited to all levels of production: from a single unit for prototype assembly, to multiple units on an assembly line. The Model PM Manual Pin Inserter easily accommodates quick change-overs. The part holding device (fixture) is simply replaced from the base of the machine. The pin diameter is easily changed, positive pin depth easily adjusted, and part size variation easily accommodated. The use of high-tech shafting and bearings results in smooth operation, precise positioning, repeatability, and durability. The Model PM Manual Pin Inserter installs pins ranging in diameter from 0.8mm-4mm (.031”-.156”) with a maximum insertion force of 0.9 kN (200 lbs).

Request for a quote

SPIROL

Germany

This versatile installation machine is suited for moderate to high production applications requiring up to 1.3 kN (300 lbs.) of installation force. The pin insertion head advances and retracts for ease of loading and unloading of the components to be pinned. The machine’s insertion bushing is positioned close to the part for smooth installation. A vibratory feeder and orientation head transfers the pin from the feeder bowl to the installation position, eliminating the need for the operator to handle the pins. A quick-clear mechanism allows for easy clearing of the feed tube without the need for tools when changing pin size or performing maintenance.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SPIROL

Germany

SPIROL's Model HC Dual Pin Inserter is a lightweight, portable, horizontal Pin Inserter designed to install SPIROL Series 550 Cosmetic Coiled Pins into plastic hinges. The cylinder/driving head modules can be moved in and out with ease, and fixture changes are simple which enables quick conversion from one assembly to another. This machine quickly and effectively delivers the pins automatically to the installation site eliminating the need for the operator to touch them during the entire assembly operation. This machine dramatically increases production efficiency with minimal operator training and effort.

Request for a quote

SPIROL

Germany

SPIROL offers a line of light duty and heavy duty Pin Driving Chucks designed to be used in SPIROL’s Manual Pin Inserters (Model PM, Model PMH or Model PMX). A Pin Driving Chuck may also be used in a drill press or arbor press with an adaptor. All Pin Driving Chucks are designed with spring tension at the tip to hold the pin securely in place prior to and during installation. The exposed end of the pin is then placed into the hole and the tool is advanced to complete the installation. The tools are supplied with a flush, above-flush or below-flush setting, depending on the application requirements.

Request for a quote

SPIROL

Germany

This versatile tool is ideally suited for low to moderate levels of production for assemblies that require installation forces up to 22.2 kN (5,000 lbs). The Model PMX Extra Heavy Manual Pin Inserter easily accommodates quick change-overs. The fixture is simply replaced at the base of the machine, and the pin diameter is easily changed by switching the pin driving chuck. This Extra Heavy Duty Manual Pin Inserter will provide smooth operation, repeatability and durability.

Request for a quote

SPIROL

Germany

The Model PMH easily accommodates quick change-overs. The fixture is simply replaced at the base of the machine, and the pin diameter is easily changed by switching the pin driving chuck. The precisely machined rack and casting results in smooth operation, precise positioning, repeatability, and durability. The Model PMH Heavy Duty Manual Pin Inserter installs pins ranging in diameter from 0.8mm-10mm (.031”-.375”) with a maximum insertion force of 6.7 kN (1,500 lbs).

Request for a quote

SPIROL

Germany

SPIROL Pin Inserters feed all common types of pins — headed or straight — as well as Bushings, Rivets, Press-In Inserts and many other similar components. Whether your requirements are for a standard Pin Inserter (with or without fixturing) or a custom designed system, our objective is to build reliable and cost effective equipment that provides the right degree of automation based on the volume and complexity of the assembly process involved; the degree of automation that yields the lowest per unit assembly cost and the optimum pay back.

Request for a quote

SPIROL

Germany

In addition to SPIROL Standard Metric Slotted Spring Pins, SPIROL offers a line of ISO 8752 Slotted Pins to meet market demand for these pins. SPIROL offers Slotted Spring Pins manufactured to the ISO 8752 specification in diameters ranging from 2mm to 12mm in both high carbon steel and austenitic stainless steel in plain finish. ISO 8752 Slotted Pins are not available with supplemental coatings such as zinc plating or passivation due to their propensity to interlock during the finishing process.

Request for a quote

SPIROL

Germany

SPIROL Standard Slotted Spring Pins SPIROL Standard Slotted Spring Pins have a slot width narrower than the wall thickness and thus do not nest or interlock. This feature, combined with a smaller expanded (pre-insertion) diameter, results in a number of advantages for SPIROL Standard Slotted Pins compared to ISO 8752 pins including: • Lower insertion force and smoother insertion. • Rounder pins, which in turn results in better conformance of the pin to the hole wall and eliminates the edge of the slot damaging the hole during insertion. • Lower stress in the spine of the installed pin. This results in longer pin life in shock or fatigue applications. • Ability to use automatic vibratory feeding of pins for installation without interlocking. • Plating of pins for additional corrosion resistance or appearance without “touch marks” or the bonding of nested pins. Please visit www.SPIROL.com to learn more!

Request for a quote

SPIROL

Germany

SPIROL manufactures Coiled Spring Pins out of 316 stainless steel to meet specific application requirements. Type 316 stainless steel is similar to 302/304 stainless steel with a slightly higher nickel content and the addition of molybdenum. The molybdenum content increases the chemical resistance of this alloy greatly. 316 exhibits superior pitting resistance against sea water, acetic acid vapors, chlorides, sodium and calcium brines, hypochlorite solutions, phosphoric acid, and the sulfite liquors and sulfurous acids used in the paper and pulp industry. This alloy is also austenitic, non-magnetic and non-hardenable using conventional methods. 316 stainless steel has better mechanical properties at elevated temperatures than 302/304 and offers excellent mechanical integrity at subzero temperatures. Typical applications for SPIROL's 316 Stainless Steel Coiled Pins include the following: marine, processing equipment, industrial, oil and gas and medical.

Request for a quote

SPIROL

Germany

SPIROL's Series 600 Superflex Coiled Pin has a loosely wrapped outer coil and a diameter at 90° to the seam equal to the hole size to provide a low insertion force and enhanced flexibility after insertion. The Superflex Pin eliminates insertion problems associated with hardened holes with sharp edges. A Superflex Coiled Pin is not distorted during insertion and maintains its straightness. One example of a great application for the Superflex Pin is when the pin is inserted into a shaft with both ends exposed for engagement into a slotted clutch component.

Request for a quote

SPIROL

Germany

The Series 500 Extra Light Duty Coiled Pins were specifically designed for use in soft or fragile materials. The 1½ coil formation ensures that the radial force exerted against the hole wall does not exceed the strength of the hole material to prevent deformation. These pins are also an economical solution where pin strength is not a major design consideration. Typical applications for Series 500 Extra Light Duty Pins include: hinge pins in plastic or ceramic assemblies, alignment pins, and fastening applications where the hole is close to an edge of an assembly component.

Request for a quote

SPIROL

Germany

You can rely on SPIROL to be a design partner that helps solve unique problems. Because we supply many customers with similar products in similar industries, we are able to meet most needs with our standard products at no additional cost. When the solution falls outside the normal requirements, we have the expertise and engineering personnel to solve those problems. By working with SPIROL in the design stage of your project, we will develop a solution that lowers your overall product cost, improves product quality, increases the robustness of your manufacturing process, and gets you to market faster. There are a number of common special Coiled Spring Pins that SPIROL has designed over the years to meet specific performance requirements. This includes making Coiled Pins from special materials such as 316 stainless steel, beryllium copper, and Inconel, or designing Coiled Pins to meet unique application requirements resulting in custom diameters, custom lengths, special features, etc.

Request for a quote

SPIROL

Germany

SPIROL's Series 880 Coiled Spring Pin was designed specifically for use as the hinge pin for PC board card lock and ejector clip mechanisms. The quality of the hinge is unsurpassed by other fastening methods due to the low insertion force and compression of the pin during and after installation. As with all Coiled Spring Pins, the Series 880 hinge pin for PC board card locks and ejector clips is self-retaining, and thus no secondary processes are required for retention. The Coiled Pin's uniform radial spring force results in a controlled hinge movement that remains consistent throughout the life of the assembly.

Request for a quoteResults for

Pins - Import exportNumber of results

58 ProductsCompany type

Category