- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special coating

Results for

Special coating - Import export

IFA TECHNOLOGY GMBH

Germany

As a specialist company according to the German Water Resources Act (WHG), IFA Technology offers expert planning and consulting for the storage of liquids or bulk materials. In the area of so-called LAU plants and systems (plants and systems for storage, filling and handling), our product range includes tank farms and silo systems which, depending on the requirements, consist of mild steel, stainless steel, plastic and GRP tanks. To meet the legal requirements, LAU plants and systems from IFA Technology can be supplied specially coated (HALAR, Teflon, etc.), varnished or painted.

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing steel / Special PTFE coated Maintenance-free dry sliding bearing | DIN 1494 / ISO 3547 TEF-MET/P is a versatile dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, it is very well suited for lubricated applications (e.g. hydraulic oil lubrication). For technical details, please visit the product page on our website!

Request for a quote

DIETZ GMBH

Germany

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

With FTJ-filter cloths, you can choose from approx. 40 high-quality fabric qualities, which fit your needs. The cloths consist mainly of polypropylene, polyester, polyamide and cotton. We would be pleased to advise you competently in the selection of the right filter cloth. In order to achieve the best results, fabric quality, grammage, air permeability and surface finish must be optimally tailored to your individual requirements. You can also get under-cloths at Filtertechnik Jäger. Drainage and cake drying can be improved. They also protect the upper cloths from mechanical wear. Special versions: Edge reinforcement Edge coating Reinforcement at supporting cam area Cloth collar from different materials Velcro fasteners Under-cloths/supporting fabric

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Gasket Sheet of Expanded Graphite, both sides with impregnation Characteristics Soft and extremely adaptable non reinforced graphite sheet with a purity of 99.85 %. Special coating on both sides raises sealabilty. Practically no cold flow or creep under temperature. Non hardening Excellent in use at cycling temperatures Excellent sealability even at low gasket stress. Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C, in oxidizing atmosphere 450 °C Pressure: p = 40 bar Main application Sensitive Flange connections like sight glasses, glass- or glass lined flanges in all industries. Suitable for In all industries Approvals BAM DVGW KTW Variant Economic grade alternative D 5.0 on request. Form of delivery Gasket sheet size of 1,000 x 1,000 mm in thickness of 1.0 / 1.5 / 2.0 mm or cut gaskets according to drawing, or EN and international Standards Special dimensions on request.

Request for a quote

MKV METALL- UND KUNSTSTOFFVERARBEITUNG GMBH

Germany

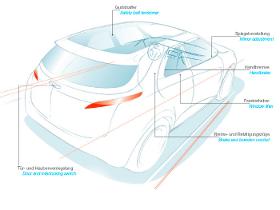

Supplementing material properties Whether it’s the automotive industry, medical technology, or machine construction: the demand for material and resource-saving development runs throughout many industries. New, lighter weight materials and new kinds of material combinations offer possible solutions. However, such solutions frequently require a specialized surface coating that balances material properties, technological requirements, and specialized operating conditions to be successful. This balancing act places high demands on system technology, which must ensure these key attributes for ever more complex components in perfectly controlled processes.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Profile gaskets and Special solutions, Expansion joints Characteristics Perfect axial and radial flexibility, good stress relaxation and protection against wear Very low leakage values through outstanding cross section and surface density. Without organic carrier fibers, no shrinkage under temperature Resistant against gases, vapours, oils, caustics and most of acids, also suitable for NH3 - gases, hydrogen, nitrogen and methanol Non hazardous to health (no Al2O3 content !) A specific vulcanisation technique for temperingsystem applications simplifies the installation and improves adaption to uneveness Main application Developed for highest thermal and mechanical strains, particularly proven in heat treatment systems, door and cover washers in foundries, power plants. Construction Wrapped gaskets from texturised glass cloth with high temperature resistant, gas proof elastomeric binders. Standard: Graphitised nonstick Coating Special: Raw, elastomercoated or PTFE impregnated...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre compressed Packing set of expanded graphite with Inconel Matrix reinforcement and special PTFE coating Characteristics Ring Set made from special high temperature resistant yarn and pore filling cross section impregnation fulfills with a tested leakage rate of 8.4 x 10 -3 mbar · l/(s·m) the leakage criteria of VDI 2440 +400 °C with a maximum allowable leckagerate of 1 x 10 -2 mbar l/(sm) and is suitable for temperatures up to +300 °C. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 100 [bar] Temperature without LiveLoading: t +300 °C Temperature with LiveLoading: t +300 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Control Valves Suitable for Power plant technology Chemical industry Petrochemical plants Boiler houses Approvals TA Luft / VDI 2440 Certificate ISO 15848-1 CC1 ISO 15848 test was conducted with 20,000 mechanical cycles and 2 thermal cycles (RT, +200 °C) and passed with a leckagerate of 6.1 x 10 -4 mg/s/m.

Request for a quote

MKV METALL- UND KUNSTSTOFFVERARBEITUNG GMBH

Germany

By specially coordinating goods movements, LNG terminals, and shaker technology, even the smallest drill holes can be optimally flushed and coated. Specialized system technology ensures optimal layer thickness distribution, on both a micro and macro level. By continuously monitoring all process parameters, such as temperatures, flow rates, conductance, pH levels, shaker function, and processing time, we are able to achieve an error rate of almost 0 ppm.

Request for a quote

FATH GMBH

Germany

To mount leveling feet, rollers, hooks or similar components; connects to the profile sideways Various shapes and designs on request Material: Die-cast aluminum, Aluminium die-cast Surface: Plain, black powder coated Specials: Other surfaces, other colors on request

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

iwis side bow chains are generally used as conveyor or drag chains in applications that require curved tracks. The chains may have different bow radii. As a rule, the pin diameter of these chains is smaller, but conical pins or bi-conical bushes are also a possibility. Highlights: • Construction dimensions of side bow chains follow standard ISO 606 • Standard sprockets can be used • Side bow chains can be supplied with special lubricants or special coatings on request • We supply side bow chains with attachments such as bent attachment plates or extended pins on request • All ELITE chain plates 1 are tapered and shot-blasted; production processes such as fine blanking and ball-drifting ensure a particularly high contact ratio • Seamless, cold-extruded, shot-blasted rollers 2 with extremely regular wall thickness • Reduced pin diameter 3 enables sideflexing (curved running)

Request for a quote

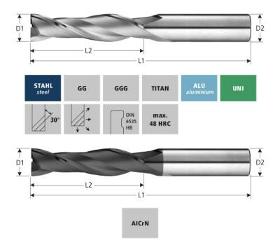

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

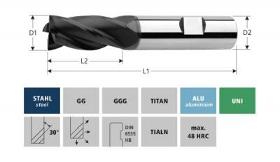

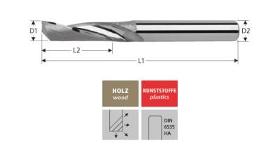

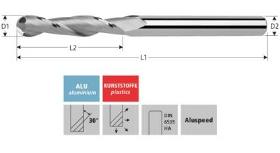

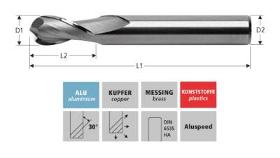

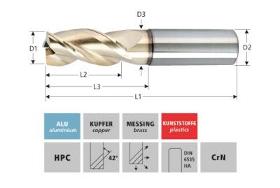

Machining non-ferrous metals is really only different from the normal machining of steel by the use of special cutting tips and coatings.

Request for a quote

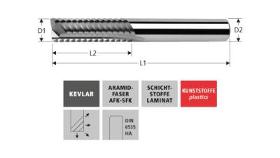

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide end mill for kevlar: with double flute, right-hand cutting, available with special coating(price on request)

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide slotting end mill: with double flute, without toric cut, extra-long, also available wit special coating

Request for a quote

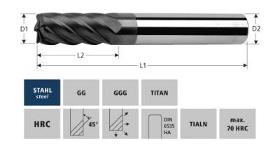

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

micrograin solid carbide end mill for hard materials: with six or up to ten flutes, right-hand cutting, upcut spiral, 45°-spiral, shank without clamping surface DIN 6535-HA, with special coating

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

micrograin solid carbide finishing end mill: with triple flute, without toric cut, right-hand cutting, upcut spiral, shank with clamping surface DIN 6535-HB, with special coating

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide toric end mill: with double flute, right-hand cutting, upcut spiral, shank without clamping surface DIN 6535-HA, also available with special coating (price on request)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

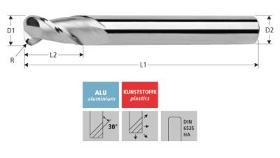

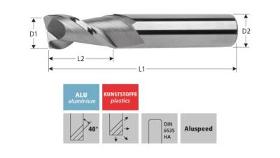

fine-grain solid carbide ball nose end mill: with double flute, right-hand cutting, centre cut, shank without clamping surface DIN 6535-HA, also available with special coating

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide finishing end mill: with triple flute, with toric cut, right-hand cutting, upcut spiral, shank without clamping surface DIN 6535-HA, also available with special coating (price on request)

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide finishing end mill: with triple flute, without toric cut, right-hand cutting, upcut spiral, shank without clamping surface DIN 6535-HA, also available with special coating (price on request)

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

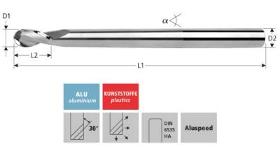

fine-grain solid carbide single flute end mill: with single flute, right-hand cutting, upcut spiral, shank without clamping surface DIN 6535-HA, also available with special coating

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide ball nose end mill: with double flute, extra-long version, right-hand cutting, centre cutting, shank without clamping surface DIN 6535 = HA / shank with clamping surface DIN 6535 = HB, also available with special coating

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide ball nose end mill: with double flute, right-hand cutting, centre cutting, shank without clamping surface DIN 6535 = HA, shank with clamping surface DIN 6535 = HB, also available with special coating

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

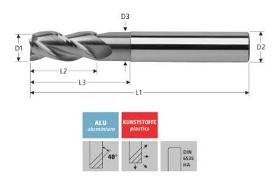

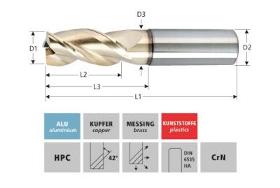

fine-grain solid carbide HPC end mill: with triple flute, right-hand cutting, upcut spiral, with toric cut, particularly suitable for high performance milling of aluminium, shank without clamping surface DIN 6535-HA, with special coating

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide HPC end mill: with triple flute, right-hand cutting, upcut spiral, with toric cut, particularly suitable for high performance milling of aluminium, shank without clamping surface DIN 6535-HA, with special coating

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide double flute end mill: with double flute, right-hand cutting, upcut spiral, shank without clamping surface DIN 6535 = HA / shank with clamping surface DIN 6535 = HB, also available with special coating

Request for a quote

ELKY GESELLSCHAFT FÜR TECHNISCHE ENTWICKLUNGEN MBH

Germany

Coated and un-coated manufactured special cables and wires made from a variety of raw materials can be used in various safety, control and attenuator elements in automotive engineering. We stock a wide, extremely varied, range of connection components in a variety of designs, sizes and materials, such as brass, tinplated copper, aluminium and stainless steel. Our products are made to customer specifications, in order to best meet their requirements (including breaking strength, elongation, flexing properties, corrosion resistance, DC resistance, low twist and low tension design, workability). Our manufacturing processes are permanently monitored and secured using appropriate procedures. As standard, we use both galvanised and stainless steel wire in accordance with DIN EN 10 264 with nominal strength of over 3000 Mpa with adequate ductility. We also use the non-corroding materials 1.4301 (AISI 304), 1.4310 (AISI 301) and 1.4401 (AISI 316) as standard.

Request for a quoteResults for

Special coating - Import exportNumber of results

28 ProductsCompany type