- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sensors

Results for

Sensors - Import export

QUELLTECH GMBH

Germany

The new QuellTech Q5 Laser Scanner Series combines the advantages of small form factors with both high resolution and scan rate. The sensor disposes of different set-up possibilities with respect to the analysis algorithm. Measurement results are delivered via Ethernet, calibrated in the X / Z plane. Special adjustable algorithms can be selected, extremely useful particularly also for optically most demanding surfaces. Time-consuming calibration tasks for the user are no more required, as the calibration routine runs on board. High Scan Rate with up to 14,000 Profiles per Second Due to an appropriate limitation of the image range (AOI) in X and Z direction, the scan rate could considerably be increased. High resolution and detection frequency with up to 14.000 profiles and 28 Mio. points per second •X measuring range from 10 to 1022 mm •Z measuring range (height) from 5 to 878 mm •Laser wave length blue 405/450nm, red 650nm

Request for a quote

QUELLTECH GMBH

Germany

Laser sensor Q4 – with a small form factor – Q4 for standard 2D / 3D measuring applications: Low sensitivity against influences of secondary light Measuring ranges from 5 mm to 1000 mm Laser wave lengths starting from UV via blue, red and green through to IR Average measuring speed up to 350 Hz frame The Q4 laser sensor has been designed to meet the requirements of standard measuring applications. Thanks to its increased flexibility, it can be used for several tasks also in complex projects. The dimensions of the ultra-compact version amount to only 86x40x25, at a weight of 140 g. Protective panes and cooling modules are available as an option. The Q4 laser sensor model enables users to obtain stable measuring results also on difficult surfaces, whether mirroring or transparent. The QS-View Standard Software comprises a comprehensive selection of application modules, to be invoked at once without previous programming steps. Customized adaptations are possible any time.

Request for a quote

QUELLTECH GMBH

Germany

Q6-Lasor sensor – High Speed, High Resolution – Q6 Sets New Standards for 2D / 3D Measurement: Resolution of up to 0.6 µm Profile speed of up to 25.000 profiles/s Measuring ranges between 2 mm and up to 370 mm available Laser wave lengths starting from UV via blue, red and green through to IR The Q6 laser sensor series has already proven its ability in numerous industrial applications demanding a high degree of precision and process stability at increased travel speed. For common environments, connection is established via GIGE interface and GeniCam. Integration with linear axes and robots is possible by means of encoder inputs and trigger option.

Request for a quote

QUELLTECH GMBH

Germany

Four QuellTech Q6 3D- laser scanners are installed, mutually displaced by an angle of 90°. In this configuration, they are able to monitor the complete surface of the cable running through. It is important that the test does not lower the production speed, therefore very high sampling rates are required, supported by convenient data processing. The measured position of a defect is recorded in cable direction.

Request for a quote

QUELLTECH GMBH

Germany

Plastic Mold Part (AC Controller) Inspection At this point the manufacturer is looking for scratches and chips and dimension specifications manually. In this respect manual inspection is not a repeatable or trustworthy method to guarantee steady quality of goods. It will be demanding for a human worker to detect this for a long period. QuellTech Solution Plastic Mold Parts are easily measurable materials for QuellTech scanners. Using the QuellTech Q4-120 Laser Line Scanner it is possible to obtain very precise reflection free 3D point clouds. A Software making necessary detections in 3D point clouds can effortlessly check dimensions and find scratches or any other defect which allows the manufacturer to automatically parse outparts that do not pass the tolerance levels.

Request for a quote

QUELLTECH GMBH

Germany

Wear is a damage consisting in gradual removal or deformation of material on solid surfaces, caused by mechanical (e.g. erosion) or chemical (e.g. corrosion) influences. In machine elements, wear may give rise to material failure or loss of functionality. For the application in question, our client has to measure wear on the surface of rollers in cement mills. Up from a certain depth, reactions are required, generated by a warning system to be developed In this project, we used several robust QuellTech Q6 scanners to cover fully the roller width. Due to the high rotational speed of the rollers, we preferred our fastest scanners for this application. We furthermore developed a software solution and implemented a warning system, based on the critical depth of the wears on the surface. By means of this system, the customer can determine the correct time for exchange of the rollers.

Request for a quote

QUELLTECH GMBH

Germany

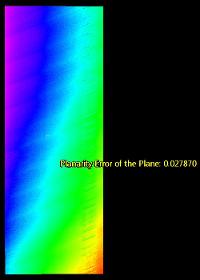

Defects to be examined in this application are very small, their size is often lower than 0.5 mm – hard to discover by human eye. Rework in the course of the production of the final product however, proves to be complicated and expensive. Large rolls with a diameter of 2 m and a length of 10 m are very difficult to remove and to reinstall. In order to avoid corresponding inconveniencies, it is essential to support the manufacturing process of the rolls themselves by a reliable quality control in the form of an automated final inspection.As the Quelltech Q6 laser scanner features an extremely precise resolution of 4096 Pixels/Profile at a high scan rate, this model proved to be able to meet the requirements and was mounted onto the positioning stage of the grinding machine. Furthermore, an industrial measurement computer was added, used for the analysis software of the point cloud. On the basis of this configuration, the entire roll surface could be recorded on a helical path.

Request for a quote

QUELLTECH GMBH

Germany

QuellTech Solution: The performance of a manual inspection cannot be compared with the speed and the repeatability of a contactless QuellTech Q4-1000 laser scanner. It is even possible to install several instruments in parallel to cover the whole width of the ingot with one single scan. These instruments are mounted on an existing portal and correctly synchronized, so that interaction of the laser light originating from the other scanners is excluded. The QuellTech laser line scanners produce 3D point cloud of the raw ingot surface, and the software calculates the coordinates of the highest and deepest levels of this surface. After scalping the flat surface can be scanned again for any defects. Benefits for the Client: Thanks to QuellTech’s wide area laser line scanners, the cycle times for ingot scalping could considerably be reduced, and excessive material scrap due to a too low scalping level is prevented.

Request for a quote

MICRO-EPSILON

Germany

The Industrial Performance Unit is a powerful computing platform for the efficient commissioning of Micro-Epsilon 3D sensors. The fully compatible controller is ideally suited to inline processes in 3D measurement tasks. The intuitive 3DInspect software with Valid3D technology enables simple and fast sensor parameter setting, which allows measurements to start immediately. The Industrial Performance Unit directly processes three-dimensional data, which is subsequently evaluated and assessed via the 3DInspect software. Results can be output via the integrated PROFINET, EtherCAT and EtherNet/IP interfaces.

Request for a quote

MICRO-EPSILON

Germany

3D sensors from Micro-Epsilon are equipped with an easy-to-integrate SDK (Software Development Kit). The SDK is based on the GigE Vision and GenICam industry standards including the following function blocks: Network configuration and sensor connection Extensive sensor control Transmission control of measurement images Management of user-defined parameter sets C++ sample programs and documentation Access to the sensor via GigE Vision is also possible without SDK using a GenICam client.

Request for a quote

MICRO-EPSILON

Germany

3DInspect is a uniform and user-friendly software tool for all 3D sensors from Micro-Epsilon. Parameter setting of the 3D sensors and recording of the measurement data are done directly in the 3DInspect software. Powerful tools allow point cloud alignment and filtering, intuitive detection and selection of relevant areas, and program combination. The 3D point clouds can be processed as required and measured values can be output to the controller.

Request for a quote

MICRO-EPSILON

Germany

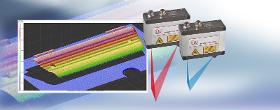

scanCONTROL 3D scanners are used for precise inline 3D measurements in numerous applications. Scans are performed by moving the scanner or the target. Due to their low weight, the scanners are ideally suited both for robotic applications and inline production monitoring. These 3D laser scanners are characterized by high dynamics, absolute precision and their compact size. With the scanCONTROL 3000 and the new scanCONTROL 3002 series, Micro-Epsilon offers a comprehensive portfolio with numerous measurement areas, Red and Blue laser technologies and extensive accessories. The scanCONTROL 3D laser scanners are based on the latest GigE Vision and GenICam standards and can therefore be integrated into a wide range of image processing environments. The powerful 3DInspect software is available for parameter setting, evaluation and output.

Request for a quote

MICRO-EPSILON

Germany

The reflectCONTROL RCS110-245 with integrated controller is designed for stationary measurements or integration into machines. This compact sensor detects anomalies on shiny surfaces which are processed and displayed as reflectivity and curvature image by software. GigE Vision enables the transfer of surface images to a wide range of image processing software packages for further analyses.

Request for a quote

MICRO-EPSILON

Germany

The high-precision surfaceCONTROL 3D 3500 snapshot sensor is used for automated optical inspection of geometry, shape and surfaces on diffusely reflecting surfaces. The surfaceCONTROL 3D 3500 is characterized by its compact design and high measurement accuracy combined with high speed data processing. With a z-axis repeatability of up to 0.4 µm, the sensor sets new standards in high-precision inline 3D measurement technology. It reliably detects the smallest flatness deviations and height differences. Two models cover different measuring fields.

Request for a quote

MICRO-EPSILON

Germany

surfaceCONTROL sensors are used for 3D measurements and surface inspections. The sensors use the fringe projection principle to detect diffuse reflecting surface and to generate a 3D point cloud. This point cloud is subsequently evaluated in order to recognize geometry, extremely small defects and discontinuities on the surface. Sensors with different measurement areas are available. This enables the inspection of the finest of structures on components as well as form deviations on large-area attachments. Powerful software packages are available for evaluation and parameter setting.

Request for a quote

MICRO-EPSILON

Germany

The interface and signal processing units extend the field of application of Micro-Epsilon sensors. The interface modules are used to convert sensor signals into digital or bus-compatible interfaces. This enables interfaces such as USB, RS422, Ethernet/IP, Profinet and EtherCAT for numerous sensors. The signal processing units are also used to record several sensor signals, to calculate and output them together. This is necessary, for example, for planarity measurement or thickness measurement.

Request for a quote

MICRO-EPSILON

Germany

The optoCONTROL CLS1000 optoelectronic fiber optic sensor is suitable for use in automation thanks to its variable switching outputs. The CLS1000 is used for reliable position monitoring as well as for position and presence detection. The fiber optic sensor comprises a CFS sensor and a CLS1000 controller. The wide detection and operating ranges of up to 2000 mm make the fiber optic sensor ideal for the detection of components even at great distances. Due to the small design of the CFS sensors, the CLS1000 optoelectronic fiber optic sensor series is particularly suitable for use in confined installation spaces.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MICRO-EPSILON

Germany

Draw-wire sensors of the wireSENSOR series measure almost linearly over the entire measuring range and are used for distance and position measurements between 50 mm and 50,000 mm. Draw-wire sensors from Micro-Epsilon are ideal for both direct integration and subsequent assembly in serial OEM applications, e.g., in medical devices, lifts, conveyors and automotive engineering.

Request for a quote

MICRO-EPSILON

Germany

mainSENSOR is based on an innovative measuring principle, which has been developed by Micro-Epsilon in order to combine the advantages of both inductive and magnetic sensors. Magneto-inductive sensors are frequently used as alternative to inductive sensors and proximity sensors in process automation, the packaging industry and in machine monitoring. Measuring the distance to a magnet which is fixed at the measurement object, the sensor outputs a continuous, linear signal. As different strength magnets are applied, measuring ranges of between 20 mm and 55 mm can be achieved. However, in order to adapt the measuring range, it is only necessary to change the magnet.

Request for a quote

MICRO-EPSILON

Germany

Micro-Epsilon offers a large range of inductive sensors for displacement and position measurement from conventional LVDT sensors and inductive sensors with integrated controller to customer-specific high-volume versions. The induSENSOR displacement sensors from Micro-Epsilon are used in automated processes, quality assurance, test rigs, hydraulics, pneumatic cylinders and automotive engineering.

Request for a quote

MICRO-EPSILON

Germany

Laser distance sensors are designed for non-contact distance measurements: laser gauges for measuring ranges up to 10m, laser distance sensors for up to 270m. These sensors are used for positioning and type classification in machine building and handling equipment.

Request for a quote

MICRO-EPSILON

Germany

White light interferometers use infrared light in the non-visible range (approx. 840 nm wavelength), which means that the measurement position cannot be seen. To visualize the measuring position, Micro-Epsilon systems are equipped with a pilot laser which projects a light spot onto the measuring position. In addition, the pilot laser uses a patented method to provide feedback on the distance in addition to the measurement position. If the measuring object is at the correct distance and within the measuring range, a constant glow is emitted by the pilot laser. If the measuring object is outside the measuring range, the pilot laser flashes.

Request for a quote

MICRO-EPSILON

Germany

New interferometer sensors with different designs and properties are available for the integration in demanding environments. Due to its 90° beam path, the IMP-DS0.5/90/VAC can also be mounted in low installation spaces. The new IMP-DS1/VAC miniature sensor is one of the smallest optical sensors from Micro-Epsilon. With a diameter of 4 mm and an integrated cable, the sensor can also be used in extremely confined installation spaces. Sensors and cables can be used both in the clean room and in a vacuum.

Request for a quote

MICRO-EPSILON

Germany

The innovative white light interferometers from Micro-Epsilon set a benchmark in high-precision distance and thickness measurements. These sensors enable stable measurement results with sub-nanometer resolution offering a comparatively large measuring range and offset distance. The interferometers are available in 3 series: the IMS5400-DS for high-precision industrial distance measurements, the IMS5400-TH for accurate thickness measurements and the vacuum-suitable IMS5600-DS for distance measurements with picometer resolution.

Request for a quote

MICRO-EPSILON

Germany

The confocalDT 2465 and 2466 confocal controllers are used for fast, high-precision distance and thickness measurements and achieve resolutions in the nanometer range. These multi-peak models simultaneously measure the thickness of up to 5 transparent layers. The controllers are characterized by high luminous intensity combined with a high measuring rate of up to 30 kHz. This enables high signal intensity even on dark or rough surfaces. The fast exposure control perfectly compensates for changing surfaces.

Request for a quote

MICRO-EPSILON

Germany

The confocalDT 2421 and 2422 controllers are used for distance and thickness measurements of diffuse reflecting and specular surfaces. Available as either a single- or a dual-channel version, these confocal chromatic measuring systems offer a low cost solution especially for series applications. The active exposure regulation feature in the CCD array enables accurate, fast surface compensation on changing surfaces. This controller is compatible with all sensor types of the IFS series covering numerous measurement tasks. The controller is optionally available as a multi-peak version for multi-layer thickness measurements. Using a special calculation function, the confocalDT 2422 dual-channel version evaluates both channels. Measurement acquisition is synchronous and can be carried out while exploiting the full measuring rate for both channels.

Request for a quote

MICRO-EPSILON

Germany

The confocalDT IFD2415 and IFD2410 are powerful confocal sensors with integrated controller. The space-saving IP65-housing enables fast integration into plant equipment and machines as no optical fiber is required. Furthermore, the IFD2410 and 2415 are ideally suited to high precision distance and thickness measurements in industrial series applications. In addition, the IFD2415 can be used with transparent materials for multi-layer thickness measurements of up to 5 layers. The active exposure time regulation of the CCD line enables fast and stable measurements of varying surfaces even in dynamic processes up to 25 kHz. The measuring system is also characterized by high luminous intensity which enables fast and reliable measurements even on dark surfaces.

Request for a quote

MICRO-EPSILON

Germany

The compact confocal IFD2411 measuring system is a factory-calibrated measuring system for industrial series applications. As well as displacement and distance measurements, the system enables even thickness measurements of transparent materials. The IFD2411 confocal chromatic measuring system is a complete channel which contains a controller and an adapted sensor with measuring ranges of 1 mm, 2 mm, 3 mm and 6 mm. This measuring system is ideal for series applications.

Request for a quote

MICRO-EPSILON

Germany

The confocal chromatic confocalDT measuring system is used for fast distance and thickness measurements. Different sensor models and controller interfaces open versatile fields of application, e.g., in the semiconductor industry, glass industry, medical engineering and plastics production.

Request for a quoteResults for

Sensors - Import exportNumber of results

311 ProductsCompany type

Category

- Sensors (284)

- Measurement and regulation equipment and instruments - pressure (37)

- Temperature sensing devices (22)

- Inductive sensors (12)

- Measurement and control instruments (12)

- Measurement - Equipment & Instruments (4)

- Machine vision system (4)

- Measurement and regulation equipment and instruments - electricity and other energy (4)

- Potentiometers (2)

- Precision measuring instruments (1)

- Dosing pumps (1)

- Measurement equipment and instruments - position and distance (1)

- Shipbuilding (1)

- Surface inspection systems (1)