- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ring

Results for

Ring - Import export

BILLI DICHTUNGSTECHNIK GMBH

Germany

O - ring seal as flexible perfection To determine which O - ring can be used , only a few important operating parameters must be defined . The temperature , the pressure and the indication of the chemical resistance determines the selection of the correct O - ring at the right application. O - rings from Billi - seals are distinguished , depending on the material , by high thermal stability, good chemical resistance and good low temperature flexibility.

Request for a quote

FATH GMBH

Germany

LED ring lamp of energy efficiency class A++ with push button for stepless dimming color temperature neutral white 5000 K color rendering Ra >80 power consumption 15 W protection class IP20 For fatigue-free and ergonomic precision work without irritating shading Well-balanced jointed arm with adjustable friction and large swivel range, 360° vertically rotatable; head joint 270° horizontally pivotable Large field of vision thanks to plastic lens ⌀ 160 mm with 3.5 diopters for distortion-free magnification of 190%, a cover prevents scratches and damages caused by focused light 1 plug-in power supply protection class II 100-240V, 50/60 Hz with 3 m connecting cable #b 3 interchangeable adapter EU/UK/US Mounting with adapter Compatible side adapter or Compatible table clamp adapter on request

Request for a quote

SYSKOMP GMBH - EMICO

Germany

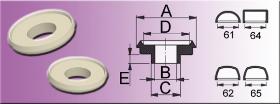

Washers for snap-on caps. These rings are applicable for cap type: 66 Material: PA Colours: natural Ring type 67 suitable for DIN 84, 85, 96, 439, 6912, 7971, 7981, 7984, 7996 ISO 1207, 1481, 1580, 4035. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Washers for snap-on caps. These rings are applicable for cap types: 61, 62, 64 and 65. Material: PA Colours: natural Ring type 60 suitable for DIN 84, 85, 96, 439, 555, 558, 571, 601, 912, 931, 934, 979, 6912, 7971, 7976, 7981, 7984, 7996 ISO 1207, 1481, 1580, 4014, 4016, 4018, 4032, 4034, 4035, 4762, 7049. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Washers for snap-on caps. These rings are applicable for cap type: 66 Material: PA Colours: natural Ring type 69 suitable for DIN 95, 97, 963, 964, 965, 7963, 7972, 7982, 7983, 7991, 7995 ISO 1482, 2009, 2010, 7046, 7047, 7050, 7051, 10642. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Washers for snap-on caps. These rings are applicable for cap type: 66 Material: PA Colours: natural Ring type 66 suitable for DIN 84, 85, 96, 439, 6912, 7971, 7981, 7984, 7996 ISO 1207, 1481, 1580, 4035. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Washers for snap-on caps. These rings are applicable for cap types: 61, 62, 64 and 65. Material: PA Colours: natural Ring type 65 suitable for DIN 84, 85, 96, 439, 555, 558, 571, 601, 912, 931, 934, 979, 6912, 7971, 7976, 7981, 7984, 7996 ISO 1207, 1481, 1580, 4014, 4016, 4018, 4032, 4034, 4035, 7049. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Washers for snap-on caps. These rings are applicable for cap types: 61, 62, 64 and 65. Material: PA Colours: natural Ring type 63 suitable for DIN 95, 97, 963, 964, 965, 966, 7963, 7972, 7982, 7983, 7991, 7995, 7997 ISO 1482, 2009, 2010, 7046, 7047, 7050, 7051, 10642. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

Washers for snap-on caps. These rings are applicable for cap types: 61, 62, 64 and 65. Material: PA Colours: natural Ring type 61 suitable for DIN 84, 85, 96, 439, 555, 558, 571, 601, 912, 931, 934, 979, 6912, 7971, 7976, 7981, 7984, 7996 ISO 1207, 1481, 1580, 4014, 4016, 4018, 4032, 4034, 4035, 4762, 7049. Dimension A has to match the dimension A of the snap-on caps.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

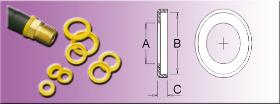

Washers with flange Wall thickness: 8.13 mm Material: LDPE Colour: yellow

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre-Loaded Packing Ring in Metal Casing Characteristics WDR-rings are ready-to-fit sealing elements for shafts and axles The wide sealing surface offers extra protection against early wear on the shaft and as well on the seal WDR rings are located in the housing with interference fit. The sealing effect is facilitated through the pre-loaded encapsulated packing. Different packing styles can be utilized depending on application Housing Standard: St 1403 galvanized Special: e.g. VA (1.4301) - CrNi Standard Insert P1P Budget to +200 °C Main application Crank and drive shafts Guiding shafts Axles, spindles and similar equipment Sealing against fluid leakage and dust penetration Protection for bearings and drive units Suitable for All Industries to seal against fluid loss or protect against dust and dirt ingress. Variant Special variantes: A 22 up to +450 °C for high temperature application S 7/G up to +250 °C for applications in abrasive environment etc. The packing insert...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Expanded natural Graphite in Purity 98 % – industrial grade or 99.85 % nuclear grade (chlorine content < 20 ppm) Temperature in steam Density min. 1.40 g/cm 3 Characteristics High cross section density Self lubrication and limited wear Dry running capability Coefficient of thermal expansion similar to steel Maintenance free and elastic, also under variable pressure Non ageing, high chemical resistance Attention! Precise tolerances and surfaces of application are requeste Operating range Pressure [p max]: 800 bar Temperature: t = -200… +550 °C pH: 0 - 14 Density: 1.80 g/cm³ Temperature in steam Density min. 1.40 g/cm 3 Main application Fittings Pumps (high temperature) Covers Valves Suitable for Valves and fittings of all Industries Approvals Oxygen BAM 200 °C/250 bar DVGW and KTW Variant Rings with integrated reinforcement or endcaps made from ANSI 316 Special quality TA Luft 300 with a leakage rate of 5.7 · 10 -3 mbar · l/(s·m) 300 °C Form of delivery ARF rings - endless,...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Safety hand-, head- and manhole seal made of biaxially expanded PTFE Characteristics Chemical universal resistance according to TRD 611 High adaptive FDA conform No hardening, does not stick to surfaces Technical parameters Temperature: t = +250 °C Pressure: p = 40 bar Main application For the application in hand-, head- and manhole opening at hotwater-, pressure and steam vessels of all kind. Suitable for Safety Gasket for Steam Boilers and Vessels As well suitable for cold pressure test Approvals TRD 401 / VdTÜV Dichtung 100 Klasse D

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Application specific ring sets Improved properties are: Extrusion resistance, if high pressures have to be sealed and/or bigger gaps than the normally recommended max of 25 of the packing size are found. Wiper function, if any micro scaling is found on the stem and at reciprocating movement with control valves Blow out safety, when sealing high compressed gases and fumes Pliability, with low gland forces as well good reset and adaptability for example in applications with temperature cycles. Ring Set 3335 For Control Valves up to 400 °C. Ring Set 6655 For Control Valves and staem applications up to 600 °C steam. All rings are delivered as standard in skive cut. Ring Set 6660 For Valves up to 650 °C steam. This ringset offers minimal volumeloss. The rings in the sealing zone are split as standard in 2 halves or as option delivered with a skive cut. Top and bottom ring are delivered with skive cut. Soot Blower Ring Set For soot blower applications with steam temperature up to...

Request for a quote

IBG HYDROTECH GMBH

Germany

With ABANO nozzle technology, approx. 15% less drive power is required. The power not required can additionally be used in the suction area. The cross-sectional area of the nozzle inserts is also reduced by approx. 15%, which creates an increased pressure size at the insert (low back pressure approx. 1 bar).

Request for a quote

KAPP NILES GMBH & CO. KG

Germany

Continuous gear honing is mainly used in the automotive industry as an alternative to generating grinding. This type of tool is also available as a set with DDG and integrated tip dressing roll. Diamond dressing gears produce the expected geometry precisely and fast and guarantee the demanded quality on the workpiece.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

This rugged and reliable liquid ring compressor expaned the NASH Vectra compressor range with a model that operates at up to 4 bar G (60 PSIG). The XM-150 comes in 681 and 682 compliant versions and is specifically designed for the higher pressures and performance requirements found in many process applications, including vapor recovery, flare gas recovery, biogas, corrosive gas handling (e.g. VCM and chlorine) and hydrogen compression. The NASH Vectra XM-150 liquid ring compressor provides the same quality and reliability you've come to expect from the existing Vectra series with these features: Single, conical port design; Between bearing rotor/shaft design; single pressure boundary sealing point; API-681 and API-682 category II/III compliance; increased bearing life; 316 stainless steel construction; and horizontal, self-draining inlet/discharge nozzles. The rugged construction and easy to service design of this liquid ring compressor reduces maintenance requirements and minimizes downtime for maintenance and repairs in even the most demanding applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

120 - 5300 CFM / 195 to 9,000 m³/h The NASH Vectra was designed around a modular platform using the most advanced computer aided design techniques, such as 3D solid modeling and finite element analysis (FEA). The modular platform offers the advantage of two versions with numerous common parts. The Vectra GL model, available from 120 to 830 CFM (200 to 1,500 m³/hr), is ideal for general industrial applications. It comes standard with internal mechanical seals and many Nash patented innovations including gas scavenging. The Vectra XL model was designed to meet the stringent requirements of many CPI applications. Whether operating as a vacuum pump or compressor, it features a 30 PSI (2 bar) differential capability. It is available in ductile iron or 316L stainless steel with a variety of shaft sealing options. Sizes range from 120 to 5,300 CFM (200 to 9,000 m³/hr). The NASH Vectra can be operated within a wide range of operating speeds, with numerous 50 and 60 HZ direct drive speeds. This increased turndown capability makes them ideal for varying load applications when driven by VFD's.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

1800 - 2600 CFM / 3,050 to 4,400 m³/h Found primarily in petroleum refineries and chemical plants, this rugged and reliable compressor handles highly toxic, explosive and corrosive gases in applications such as flare-gas, chlorine and Vinyl Chlorine Monomer (VCM) recovery. Together with the 14 new GARO models and other NASH liquid ring compressors, the NASH HP-9 compressor form the NASH core compressor product line, which provides compression greater than 200 psig (15 Bar abs). Low pressure compressors are available to 30 psig (3 Bar abs), and 20,000 CFM (34,000 m³/hr). As a result, NASH offers the widest pressure and capacity ranges of liquid ring compressors available worldwide.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

100 - 1800 CFM / 170 to 3,050 m³/h The GARO line of liquid ring compressors expands the capacity and pressure ranges of the Nash line to meet the ever growing requirements of our customers. Found primarily in petroleum refineries and chemical plants, these rugged and reliable compressors handle highly toxic, explosive and corrosive gases in applications such as flare-gas, chlorine and Vinyl Chlorine Monomer (VCM) recovery. The GARO line, available in single and two-stage designs, comes in: cast iron, stainless steel, carbon steel, spheroidal cast iron, 316 stainless steel, duplex stainless steel, and Hastelloy or Titanium on select models. Together with other NASH liquid ring compressors, including the HP-9, the 14 GARO models form the NASH core compressor product line, which provides compression greater than 200 psig (15 Bar abs). Low pressure compressors are available to 30 psig (3 Bar abs), and 20,000 CFM (34,000 m³/hr). As a result, NASH offers the widest pressure and capacity ranges of liquid ring compressors available worldwide.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

3000 - 16000 CFM / 5,100 to 27,200 m³/h The NASH 905 is a redesign and upgrade of the NASH 904. Capacities of the 904 pumps range upward from about 3,000 CFM at vacuum. These durable compressors can handle excess liquid carryover without any difficulty, even if it arrives as massive slugs. 904 compressors are found in many industries, including Paper, Chemical, and Mining. The 905 series has been designed to provide superior reliability and performance in harsh applications such as chemical processing or geothermal power generation. Constructed of 316L stainless steel, the 905 series offers excellent corrosion resistance and can be outfitted with a variety of mechanical seals. It also includes a patented gas scavenging feature.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Suction capacity 6,000 to 11,00 m³/h The NASH 2BQ1 590 has a unique performance range. It combines a high gas flow rate (6,000 to 11,000 m³/h) with a discharge pressure range of up to 3.75 bar abs. The standard 2BQ compressor model is equipped with a duplex steel shaft, ductile iron end shields, a massive stainless steel housing and o-rings to seal housing components. Higher quality materials are available on demand by using the modular 2BE3/4 design. The NASH 2BQ1 is certified for ATEX.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Suction capacity 125 to 1400 m³/h; Vacuum to 33 mbar abs.; Discharge pressure to 2.0 bar abs. The NASH 2BM1 magnetic drive pump series is capable of achieving volume flow rates of 125 to 1400 m³/h and vacuum of 33 mbar abs. Non-contact torque transmission is achieved by using a permanent magnetic drive system. The pump's inner working space is hermetically sealed from atmospheric conditions, eliminating any possibility of leakage. This seal is essential for demanding applications, such as processes that are required to meet the most stringent standards on environmental compatibility. ATEX applications are also possible, certifications are available.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

The NASH 2BE5 was developed from the proven NASH 2BE3 and 2BE4 compressors, whose reliable performance has been further improved. The development focused on optimizing performance, higher vacuum capabilities and ease of maintenance. NASH 2BE5 Benefits include: improved efficiency higher vacuum levels (to 100 mbar abs / 3" Hg abs) built-in ECO-FLO™ water saving technology with patent pending gas scavenging drop in replacement for 2BE3 and 2BE4 removable bearing brackets for easier maintenance elimination of tie rods, resulting in improved sealing due to bolted casing joints polyisoprene lining The footprint and connections to the NASH 2BE5 models are identical to its predecessors, the NASH 2BE3 and 2BE4. Therefore, exchanging or upgrading to the more efficient NASH 2BE5 requires no site modifications. The NASH 2BE5 model is available in cast iron, with stainless steel coming soon. The 2BE5 is perfect for use in mining, filter applications, paper mills, power plants, chemical plants, refineries and more.

Request for a quoteResults for

Ring - Import exportNumber of results

25 ProductsCompany type