- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pumps

Results for

Pumps - Import export

IFA TECHNOLOGY GMBH

Germany

The conveyance of highly viscous products is part of our technical expertise. Feed pumps must meet the requirements for a long useful life, low maintenance and wear-free operation. We at IFA Technology live up to this claim by installing the most suitable pump in each of our systems. We use all types of pumps, from centrifugal pumps to gear pumps and piston pumps. Depending on the type of medium and its application requirements, we can design and offer you the suitable shaft seal. This includes among others packing gland seals, mechanical seals or magnetic couplings.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

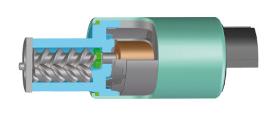

Technically superior FLEXCORE is a product innovation in the true sense of the word. Our new screw pump stands out from the crowd particularly through its easy-to-change insert which guarantees lasting peak performance. Modern design teamed with unique functionality provides flexibility during installation you have never experienced before. Made for demanding applications in the naval, energy, mechanical engineering, oil, and chemical sectors guarantee superior performance data and provide maximum operational reliability The first pump that is adaptable The FLEXCORE pump family is the next evolutionary stage in the pump sector. Thanks to the unique modularity of the housing and the patented pump insert, it can adapt flexibly to any installation position and standard. FLEXCORE provides a higher flow rate at a smaller size. Extremely robust, virtually wear-free, and uniquely easy to maintain.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

With the modular structure of our pump ranges, we are able to fulfill a wide range of different pumping tasks. Our pumps are two, three or five-spindle, single or double-volute, self-priming displacement pumps for the low / medium or high-pressure range. They are used to pump a wide variety of different fluids with various lubrication properties. In order to meet the high demands on wear protection, service life or flow rate, it requires a high vertical range of manufacture. We manufacture our spindles and housings (the core elements of Leistritz pumps) ourselves in Germany.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

Leistritz Multiphase pump systems are in operation worldwide. They are designed for running with high gas volume fractions (GVF) and gas bubbles with up to 100% gas content as well as for capacities of up to 5,000 m³/h and differential pressures of up to 150 bar. In comparison with traditional upstream installations, multiphase pumps need neither space-intensive separation devices at the borehole nor separate pumps, compressors or pipelines to transport gas and fluid to the central collection areas. Multiphase pumps are a cost-effective technology for the transportation of multiphase fluids using just a single pipeline - instead of separating the oil, water and gas at the collection areas and exporting the oil and gas to the central production facilities via separate pipelines. In general, multiphase pumps are a way to accelerate the unprocessed gas/fluid mixture.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

The fuel systems division specializes in the development and production of serial products. Two main products are produced and sold: fuel pumps which are used in vehicles and flow meters in fuel dispensers which work on the screw spindle principle. Both products meet the high requirements demanded by the automotive and tank facility industries with regard to performance, accuracy and quality. The high overall efficiency in comparison with other pump stages, the low noise emission and the pump's high dirt resistivity as well as the outstanding controllability of a displacement pump make our pumps a reliable and important module in the delivery unit.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

Leistritz Multiphase pump systems are in operation worldwide. They are designed for running with high gas volume fractions (GVF) and gas bubbles with up to 100% gas content as well as for capacities of up to 5,000 m³/h and differential pressures of up to 150 bar. In comparison with traditional upstream installations, multiphase pumps need neither space-intensive separation devices at the borehole nor separate pumps, compressors or pipelines to transport gas and fluid to the central collection areas. Multiphase pumps are a cost-effective technology for the transportation of multiphase fluids using just a single pipeline - instead of separating the oil, water and gas at the collection areas and exporting the oil and gas to the central production facilities via separate pipelines.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

Twin-screw flow meters for all standard fuels in fuel dispensers. Leistritz flow meters used by many service station operators as the measuring units in the fuel dispenser. They distinguish themselves with their high accuracy for low-viscosity media. The fuel measured by the flow meter flows in axially, causing spindles to rotate smoothly and evenly. The number of rotations caused by the volume of fuel flowing through is metered by an electronic pick-up, which transmits the pulses to a calculator for display. The principle ensures an extremely long service life for the product, reduced operating costs and longer maintenance intervals for our customers.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

Twin-screw pump as a fuel pump for the automotive industry. Leistritz pumps are used in a wide range of vehicles and pump modules. The high overall efficiency in comparison with other pump stages, the low noise emission and the pump's high dirt resistivity as well as the outstanding controllability of a displacement pump make our pumps a reliable and important module in the delivery unit. These are major advantages, particularly in view of the ever higher and stricter requirements for exhaust standards.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

Multiphase pumps are successfully used for onshore applications around the world. The technology has become firmly established among the global oil and gas producers since it allows production to be maintained on small oil fields with declining production as well as making the reduction of the flaring of petroleum gas possible as a contribution to a clean environment.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

ViscoTec Dispenser 3VMP18 as a volumetric dosing pump for larger volumes ensures an even and reliable product supply of viscous, structure-sensitive and solids-laden products - with a repeatability of +/- 1 %! Absolutely precise, uniform and reliable dosing of various media and handling of larger volumes. Alternating opening chambers ensure gentle product transport and pulsation-free output. Your advantages: - no dripping or thread pulling due to programmable retraction - direct linearity between spread rate and speed - constant dosing volume even with fluctuations in density, viscosity and temperature - reliable dosing without heating the medium - drive with servo or three-phase motor - easy programming of quantity and speed - low maintenance, quick disassembly - free inlet possible, as self-priming operation

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-L 3 / 18 barrel emptying system offers a modern way of emptying containers.The connection with the ViscoTec VMP dispenser series for the removal of the medium offers the following advantages: - container sizes from approx. 50 l to 300 l - viscosities of approx. 80,000 - 2,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - removal of materials loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: Removal of materials directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

2-component dosing solution with optimum installation space design cascadable multiple dosing system with small dosing head distances minimum space requirement in automation systems. The ViscoDuo-P 4/4 2-component dispenser is a valveless, static, space-saving mixing head with dispensers arranged directly in front of the mixer. The EC version dispensers have been specially designed for easy cleaning (Easy-Clean) and checking of the pump interior. No valves are required in the mixing head. The components to be mixed are metered into the static mixing tube purely volumetrically via the dispenser without dead space. Your advantages: - Processing of viscous materials, unfilled as well as very highly filled supply of the medium with only low inlet pressure - Setting the desired mixing ratio by adjusting the speed ratio of the two dispensers - sensors integrated without dead space in each component for online process monitoring - Withdrawal possible

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

Additive manufacturing processes are a great alternative to classical processing techniques and aim at a constructionally optimized and cost-effective production of components. 3D printing now includes a variety of technologies that can be used in different 3D printer versions. ViscoTec uses established dosing systems with the endless piston principle specifically for 3D printing of viscous fluids and pastes. And it creates new possibilities for printing 1-component viscous fluids and pastes.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

Now also available from stock: High-quality"½" standard dosing needles, as well as conical and conical black dosing needles for UV applications. In addition to the existing range of mixers and super precision needles, preeflow now also offers"½" dosing needles in various designs. The quality makes the difference: This applies to the dosing systems as well as to the required consumables such as needles and mixers. The years of experience of ViscoTec and the needle manufacturer led to the use and production of premium dosing needles. The processing and design of the dosing needles and the mixer optimizes the application and dosing accuracy of the dispenser. The high-quality needles reduce material losses and improve production performance better than comparable competing models through fast, uncomplicated changeovers and high-precision outputs.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The endless piston principle convinces in handling abrasive ingredients: Fillings and dosages in the cosmetics industry are subject to strict guidelines. In addition to the statutory and market standards, there are those required by the product itself. In this case, these are gels with microparticles which push some dosing systems to their limits in the manufacturing process. The contained microparticles, such as ground stone fruit seeds or alumina or plastic particles are very abrasive, but peeling pastes and body scrubs can no longer be imagined without them. Exactly this effect is desired by the consumer in order to remove surface layers of the skin. However, the handling of these highly abrasive pastes is often difficult or damages pumps and other processing machines and increases the wear of the systems extremely ̶ and thus also the running costs.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The preeflow® controllers simplify every dispensing process. They are perfectly matched for all dispensers within the eco-PEN, eco-DUO and eco-SPRAY series. The eco-CONTROL EC200 2.0 serves primarily to control and parameterize the preeflow® dispensers. In addition, pressure monitoring is carried out by the controller for a reliable process with precise dispensing results. The control unit can be easily integrated into fully automatic systems and meets all requirements of modern dispensing processes. The eco-CONTROL EC200 2.0 offers a compact solution with an integrated power supply unit. The control unit also offers options for pressure and temperature monitoring, 100 program memory locations and enables fast and clean storage of programs. The control unit can also be integrated with PLC systems.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Continuous volumetric and pulsation-free dosing regardless of viscosity ▪ For low viscosity and self-levelling materials (e.g. trickle resins) ▪ Low wear solution due to avoidance of material contact at shaft seal ▪ Uninterrupted production thanks to material reservoir with up to 350 ml usable volume ▪ Pressure and temperature sensor including sensor holder at pump outlet ▪ Level programmable using analog level sensor ▪ Filling under atmospheric pressure ▪ Optional connection for process gas (max. 0.2 bar pressure) ▪ Dispenser holder for easy and stable installation ▪ Increased process reliability due to integrated safety device ▪ Dividable rotor assembly for easy & fast replacement and low spare part costs

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

ViscoTec 1C dispenser vipro-PUMP ▪ Volumetric dispensing, regardless of viscosity ▪ For low to high viscosity materials ▪ Particularly suitable for highly abrasive, filled or shear sensitive materials ▪ Modular scalability of volume flow within the model range ▪ Programmable suck-back prevents dripping or stringing of product ▪ Material entry with Tri-Clamp DN 20 connection for optimized material flow and fast coupling of material supply ▪ Locking ring for easy and fast disassembling of drive unit ▪ Drive unit connection with optimized power transmission free from clearance ▪ Optimized dispenser bracket for easy adjustable mounting ▪ Long lifetime due to low wear ▪ Different rotor and stator materials available ▪ Continuous dosing, pulsation free ▪ Interior non-stick coated ▪ Dividable rotor assembly for easy & fast replacement and low spare part costs ▪ Easy cleaning and maintenance due to quick assembly and disassembly options

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

In order to avoid chemical reactions such as curing or crystallization during the dosing process, any contact with metal in the area in contact with the material in the dispenser was avoided. The materials used have been carefully selected: On the one hand with regard to chemical resistance to adhesives and other fluids and on the other hand with regard to highest resistance to physical wear by abrasive media. Highly reactive materials such as sulfuric acid, anaerobic UV curing acrylates and electrolytes require special treatment. They can be dosed with highest accuracy and best repeatability. The new metal-free dispenser can be easily installed on existing ViscoTec drive technologies and offers the same advantages as other proven dispensers from the portfolio of the dosing technology specialist. The metal-free dispenser is available in many sizes.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The eco-PEN330 precision volume dispenser made by ViscoTec enables many applications in the low to high viscosity dispensing range. The preeflow® eco-PEN is a rotating, absolutely pressure-tight displacement system consisting of a self-sealing rotor and stator. The controlled rotary movement of the rotor generates the flow by displacing the medium in the stator. Pumping without changing the medium is guaranteed. As the material can also be conveyed backwards, preeflow® guarantees a clean, controlled material or medium tear-off without dripping. - True volumetric dosing - Retreat effect - Viscosity-independent dosing - Easy cleaning - dosing independent of inlet pressure - Adjustable dosing flow - Pressure-tight without valve - Dosing pressures from 16 to 20 bar

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

Examples of materials for dosing: 1- and 2-component epoxy, UV / light-curing / thermosetting adhesives, highly filled materials, anaerobic adhesives, shear-sensitive adhesives, heat-conducting paste, sealants, flavourings, silver conductive paste, flux, perfume, isopropanol, industrial oils, silicone, alcohol, grease, paint and ink, MEK, braze paste, PU, acetone, petrol and many others. The preeflow® eco-DUO is a rotating, absolutely pressure-tight displacement system consisting of a self-sealing rotor and stator. The controlled rotary movement of the rotor generates the flow by displacing the medium in the stator. Pumping without changing the medium is guaranteed. As the material can also be conveyed backwards, preeflow® guarantees a clean, controlled material or medium tear-off without dripping. Application: - point dosing, with highest volumetric accuracy - bead application with application speed adjustable to the web speed - Potting technology

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

Precise atomisation and spraying can be continuous or selective. The revolutionary combination of continuous flask and low-flow spray chamber guarantees perfect spraying of low to highly viscous media with high edge sharpness and minimum overspray. Fields of activity: - Dosing - Coating - Microsputtering - Lubrication - Marking and much more. Materials: - Fats/oils - Colours - Activators/primers - Abrasive materials - Adhesives - Silicones - Solid-laden materials and much more. Advantages: - Constant quantity/area - Uniform spray pattern - Uniform coating - Little overspray/high edge sharpness - Defined volume per revolution - High chemical resistance - High spread - Adjustable round jet - From dot spraying to continuous spraying - Low-maintenance system - flow rate of the medium and atomising air can be regulated independently - High application efficiency

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

ViscoTec Dispenser 3VMP22 as a volumetric dosing pump for larger volumes ensures an even and reliable product supply of viscous, structure-sensitive and solids-laden products - with a repeatability of +/- 1 %! Absolutely precise, uniform and reliable dosing of various media and handling of larger volumes. Alternating opening chambers ensure gentle product transport and pulsation-free output. Your advantages: - no dripping or thread pulling due to programmable retraction - direct linearity between spread rate and speed - constant dosing volume even with fluctuations in density, viscosity and temperature - reliable dosing without heating the medium - drive with servo or three-phase motor - easy programming of quantity and speed - low maintenance, quick disassembly - free inlet possible, as self-priming mode of operation

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XS hobbock emptying system offers a modern way of emptying containers.The following advantages result from the use of eccentric screw pumps for the removal of the medium: - container sizes from approx. 5 l to 50 l - viscosities of approx. 80,000 - 2,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: - Removal of media directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers - direct dosing as pulsation-free flow rate

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XL drum emptying system offers a modern way of emptying containers. The following advantages result from the use of eccentric screw pumps for the removal of the medium: - container sizes from 50 l - viscosities of approx. 80,000 - 2,000,000 mPas - Bridge frame can be driven underneath with drums on pallets - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: - Removal of media directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The compact 3RD4-EC dispenser from ViscoTec ensures an even and reliable product supply of viscous, structure-sensitive and solids-laden products. Absolutely precise, uniform and reliable dosing of various media, such as adhesive dosing or sealant dosing, thanks to the special rotor-stator geometry. Alternating opening chambers ensure gentle product transport and pulsation-free output. Your advantages: - interior non-stick coated - no dripping or thread pulling due to programmable retraction - direct linearity between spread rate and speed - constant dosing volume even with fluctuations in density, viscosity and temperature - reliable dosing without heating the medium - long service life due to media-specific component selection - easy cleaning and condition check of the pump interior - quick disassembly

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

ViscoTec Dispenser 3VMP36 is a volumetric dosing pump of larger volumes for an even and reliable product supply of viscous, structure-sensitive and solids-laden products - with a repeatability of +/- 1 %! Absolutely precise, uniform and reliable dosing of various media and handling of larger volumes. Alternating opening chambers ensure gentle product transport and pulsation-free output. Your advantages: - no dripping or thread pulling due to programmable retraction - direct linearity between spread rate and speed - constant dosing volume even with fluctuations in density, viscosity and temperature - reliable dosing without heating the medium - Drive with spur gear motor and optional forced cooling fan - easy programming of quantity and speed - low maintenance, quick disassembly - free inlet possible, as self-priming operation

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoTreat-R preparation and feeding system ensures an even and reliable product supply. At the same time, the medium is optimally prepared for the production process by stirring and circulating. The use of the VRP dispenser series for the further transport of the medium offers the following advantages: optimal processing of viscosities up to 50,000 mPas very low shear stress of the medium very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - no air supply necessary - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - Stator material is adapted to the medium to be pumped Application: - Feeding and processing of medium to highly sensitive media, e.g.: Silicones, adhesives, resins, greases, colour pastes, metal-filled pastes

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

Application: Point dosing with highest volumetric accuracy - bead application with application speed adjustable to the web speed - encapsulation technology Areas of responsibility: - Electronic components - Semiconductor production - LCD/LED/OLED - Photovoltaics - Medical technology - Biochemistry - Laboratory - Optics and Photonics - SMD/SMT Technical Data: - True volumetric dosing - Retraction effect - Viscosity independent dosing - Easy cleaning - Inlet pressure independent dosing - Adjustable dosing flow - Pressure tight without valve - Dosing pressures up to 40 bar

Request for a quoteResults for

Pumps - Import exportNumber of results

61 ProductsCompany type

Category

- Pumps (48)

- Dosing pumps (38)

- Pumps, hydraulic (6)

- Dosing - machines and equipment (6)

- Plastic packaging (6)

- Bottling and filling - machinery and equipment (2)

- Applicators for adhesives and glues (2)

- Chemicals and pharmaceuticals - packaging machinery (1)

- Cosmetics industry - machinery and equipment (1)

- Gas and oil - exploitation (1)

- Goods handling systems, continuous (1)

- Industrial piping (1)

- Mixers (1)