- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- process automation

Results for

Process automation - Import export

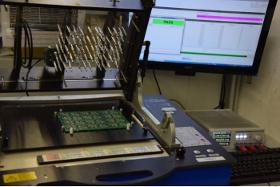

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Placement tests, checking the electrical and software functionality, launch tests – depending on your individual requirements and your component, we will develop a test strategy and tune the tests to fit with each other. Our comprehensive test development methodology accelerates processes running all the way to the delivery of your product and reduced testing costs.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. When planning tests, we work to your test specifications or develop a cost-optimised, efficient concept. In our tests, we simulate real usage conditions. In this way, we make sure that devices, systems or components will function correctly. Quality management at PRUFREX also includes developing efficient testing strategies.

Request for a quote

TRIBO-CHEMIE GMBH

Germany

Aqueous forging lubricant for hot- und warm die forging and extrusion Properties and Advantages • universal product for a wide range of application, especially deep cavity forging • film withstands several strokes from the hammer (up to 3) • replacement for saw dust thus improved die life, no smoke and increasing process reliability • automation possible = improved work environment • above average release property (effective expulsion) during the metal forming process • improved tool life (reduced wear) due to immediate formation of a heat-resistant and a protective film • excellent metal flow • perfect accuracy of the components produced, no build-up of inorganic residues • economical in use

Request for a quote

MICRO-EPSILON

Germany

mainSENSOR is based on an innovative measuring principle, which has been developed by Micro-Epsilon in order to combine the advantages of both inductive and magnetic sensors. Magneto-inductive sensors are frequently used as alternative to inductive sensors and proximity sensors in process automation, the packaging industry and in machine monitoring. Measuring the distance to a magnet which is fixed at the measurement object, the sensor outputs a continuous, linear signal. As different strength magnets are applied, measuring ranges of between 20 mm and 55 mm can be achieved. However, in order to adapt the measuring range, it is only necessary to change the magnet.

Request for a quote

MICRO-EPSILON

Germany

Micro-Epsilon offers a large range of inductive sensors for displacement and position measurement from conventional LVDT sensors and inductive sensors with integrated controller to customer-specific high-volume versions. The induSENSOR displacement sensors from Micro-Epsilon are used in automated processes, quality assurance, test rigs, hydraulics, pneumatic cylinders and automotive engineering.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DIETZ GMBH

Germany

Bent wire parts represent a separate part of our production range. Bent parts differ from springs such as extension springs, compression springs and wave springs in terms of how they are produced. This type of spring is not only processed with automated machinery, but also involves a considerable amount of special handling, which we perform using our range of state-of-the-art equipment. Precision production with our high-tech machinery: Our range of machinery with an in-house toolmaking workshop enables three-dimensional bent parts to be produced with a wide variety of forms and with specialised finishes applied to the ends. Our range of machining processes includes: Bevelling, embossing, thread cutting, thread rolling, turning and milling. For bent wire parts, both CNC bending and mould-based bending are possible as production solutions.We process wire thicknesses of 0.20 to 8.00mm.Tool-based: 0.50 to 8.00 mm. Coating of part surfaces: Oiling, Vibratory finishing, Galvanisation.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). To manufacture self-supporting coils, we use self-bonding wire. During winding, the surface of the wire is bonded using hot air. To ensure the coil connections can be soldered, they are then stripped of insulating enamel using a fully automated milling process. PRUFREX is able to make air core coils with wire thicknesses from 0.045 to 1.6 millimetres.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

This special Metzner development is able to process cable wires with a diameter of up to 28 mm. The cycle time for this is 2000 mm / 35 seconds. The processing steps include long slitting, sawing, circumferential cutting, stripping, brushing and depositing. An integrated ink jet printer labels the cable wires with information or markings. As the heart of the processing method, Metzner uses a newly developed stripping head that combines a rotary cut with a powerful clamping and simultaneous rotation of the material. This enables a high-precision, multi-stage radial cut through the various layers of material. Microscopic quality inspection confirms that the processing is flawless with no scratches, pressure or abrasion marks. In addition to the high machining quality, the machinery also offers special precision: both the overall length and the machining position are maintained with an accuracy of 0.2 mm. The machine can process cable wires with diameters up to 28 mm.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has a clear understanding of the future and transforms existing processes into fully automated system solutions. Workstations that were previously operated separately are now combined into fully automatic production lines. The starting point of an automatic processing line is the cable that is wound on a reel. The end result is a finished cable with a completely assembled plug system

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The AM 3000 range of cable processing machines are distinguished by cutting and haul-off power and their convincing modular, robust and long-life construction for continuous industrial working. There are different models with different cutting powers and specifications. To match the processing requirements, numerous knife contours and technologies are available: The patented „ double-knife system“ facilitates different processing in a single working pass, the circumferential rotary technology offers exact circular cutting for cables with very thin or rigid outer insulation cover and for co-axial cables. Every model is equipped as standard with a full set of interfaces for peripheral equipment and IT integration. The machines can easily be converted into complete production lines, thus further increasing the process automation.

Request for a quote

LEONI DRAHT GMBH

Germany

Compacted material terminals made from Cu-ETP1 and Cu-OF1, in bare and tin-plated, nickel-plated and silver-plated upon request, in hard or soft annealed. Cross-section ranging from 1 mm² to 95 mm² depending on welding area. Compact welded terminals of different copper strands can be automated processed. A production of individual parts is possible as well as large-scale production. Resistance welded strands by LEONI are particularly suitable for high-voltage battery connectors, for high power connectors, for switch contacts and for special applications.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

A CMMS is a software solution that centralizes maintenance information, facilitates processes, and automates some tasks to improve efficiency. Computerized maintenance management system software optimizes the use, availability, and life span of equipment, machinery, fleets, infrastructures, facilities, or operations.

Request for a quoteResults for

Process automation - Import exportNumber of results

13 ProductsCompany type