- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high line

Results for

High line - Import export

TRIBO-CHEMIE GMBH

Germany

Properties and Advantages • improved metal flow, superior die filling, lower die pressures • spontaneous formation of a thin, uniform lubricating film; in that way a perfectly sprayed film without blank spots is achieved • protection of die steel from erosion • no build-up inside the die cavity • improved die life • shorter spraying cycle • no blocking of spray nozzles and maintenance/problem-free production, even under most severe forging conditions • cost-efficient

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. So you want to achieve compact shapes for complex components? Our test and programming service is there for you. The system we use keeps line contact high, offers perfect access and ensures precise bonding. The advantages for you: flexible program selection until shortly before the start of production, no extra expenditure for external programming.

Request for a quote

GRONBACH

Germany

Gronbach develops downdraft extraction systems and cooking hobs for all types of cooking styles, both as ordered by customers and on our own initiative. Based on our network of ceramics and electronics suppliers, and with a modern production line with a high degree of automation, our site in Niederndorf produces cost-efficient, large-scale production models as well as exclusive models with sophisticated original materials.

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

The 32 valve printhead is ideal for large character, high-speed production line marking and coding, available with mini, midi, and maxi nozzle options.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The travelling circular knife machine CCM 6 cuts rigid profiles and tubes accurately to length. The CCM 6 achieves very long processing times of several seconds for excellent "final trim quality" thanks to a standard servo linear drive for the tool carrier, and at the same time extremely short cycle times of less than one second for machining short parts at high line speeds. Added to this is the servo linear drive for circular knife feed with different feed speeds for different material sections, e.g. a gentle material penetration or knife exit with low feed to reduce burr formation. High speed ranges As far as the knife speed is concerned, we offer you outstanding possibilities of alternatively 2,000 – 6,000 rpm or 4,000 – 12,000 rpm. This means that there are no limits to the use of various types of circular knives, including clamping and grinding in continuous operation. Our product videos will give you an insight into the machining process.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

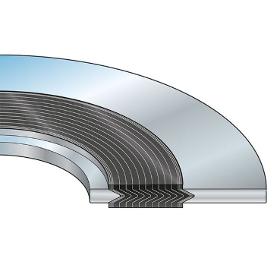

Spiral wound gasket made of crimped metal tape with sealing wraps of non asbestos gasket material. Optional: inner and/or outer metal ring. Characteristics For flange connections in high pressure pipe line construction and fittings Extremely low leakage with PTFE spiral. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance to 550 °C with graphite spiral Media resistance: pH 0 - 14 Max. pressure load: p = 400 bar Temperature range: t = -200 to +550 °C Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C Pressure: p = 400 bar Main application High temperature and high pressure flanges Piping Pressure vessels Heat exchangers Fittings Suitable for Power plants Petrochemical plants Chemical industry Material Centerring ring OD: Carbon Steel galvanized Spiral: 316L Centerring ring ID: Carbon Steel galvanized Other material combinations on request Product Types SF 11 Spiral wound gasket without any center ring for flanges with tongue and groove connection SF...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

High line - Import exportNumber of results

6 ProductsCountries

Company type