- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- goods handling

Results for

Goods handling - Import export

MIAS MASCHINENBAU, INDUSTRIEANLAGEN & SERVICE GMBH

Germany

Load handling devices for containers and cartons As units that need separating and handling become smaller and smaller, automatic small components warehouses are increasingly gaining ground in intralogistics. No fast and efficient logistics system can do without them. With its systems and load handling devices, MIAS has been ensuring the fast and reliable storage and retrieval of cartons and containers for decades. Many containers are now divided into compartments to further increase their capacity. This means they have to be accessed more frequently. Here, performance and reliability are essential.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers the complete range of conveying systems, storage systems and handling systems in mechanical engineering. Our plants and systems can be integrated into your own conveyor line or designed as completely automated systems. External plant components can also be integrated into our superordinate control system. Our plants and systems are mainly used for bagging or bottling or batch loading systems. Application of conveying, storage and handling systems: Dosing and application of liquids in the plant process Dosing and mixing of powders, fibres and liquids Bagging and bottling systems integrated into a production line Silo systems and tank systems with conveying paths and mixing systems Pipe shell plants

Request for a quote

IFA TECHNOLOGY GMBH

Germany

In the plastics industry, the mixing and dosing of liquids and solids finds further areas of application. IFA Technology develops customised special plants for the plastics industry. Particularly in the plastics industry, you benefit from our special know-how in temperature control of complete production plants. Application of plants and systems for the plastics industry: Storage, mixing and dosing of liquids such as liquid plastics with high working temperatures (polyamides such as Caprolactam and Laurolactam), binders and additives

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology GmbH has been working for the wood-based materials and panels industry for more than 35 years. Our liquid dosing and solids dosing systems offer various applications for optimising your processes. IFA Technology has made a name for itself in the wood-based materials industry and is known worldwide. Application of plants and systems for the wood-based materials industry: Storage, mixing and dosing of liquids such as impregnating resins, adhesives, glues, flame retardants and biocides Reactor systems for the production of glues and phenolic resins, urea resins or melamine resins

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers tailor-made plants and systems for the animal feed industry. Our mixing and dosing systems process both liquid and solid components, which are used for the production of animal feed, mineral feed and supplementary feed. To supplement our plant systems, we also offer adapted silo systems and tank systems as well as multifunctional filling systems and bagging or bottling systems for all types of containers. Our animal feed plants and systems are made of high-quality stainless steel and use food-grade materials and FDA-approved (Food and Drug Administration) components. Our focus is on hygiene and the diligence of the respective plant processes. The latest plant technologies guarantee the required degree of accuracy, economy and process reliability.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology considers your individual requirements and builds customised plants and systems for the paint industry and the varnish industry. Our plants and systems for dosing liquids and solids in the paint and varnish industry offer high dosing accuracy and perfect reproducibility. We meet the high demands of our customers through the use of high-quality materials and precise workmanship. Application of plants and systems for the paint industry and the varnish industry: Storage, mixing, dosing and application of paints and varnishes Special dosing valves and dosing pumps for paints and varnishes

Request for a quote

IFA TECHNOLOGY GMBH

Germany

In the insulation material industry IFA Technology has established itself internationally as a reliable partner in many important production and processing steps. In close cooperation with our customers, we always develop economical solutions to meet the constantly changing requirements of the market. We consider your individual requirements and build customised plants and systems for the insulation materials industry. In the field of mineral wool insulating materials, we specialise in manufacturing binder mixing systems and process water treatment plants. In this segment in particular, the properties of insulating materials are constantly changing. Together with our customers we continuously develop new systems to meet the requirements of the market. Thanks to many years of know-how, we are always able to implement the most economical solution from the customer's point of view.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

We consider your individual requirements and build customised chemical plants and reaction systems for you. Plants for processing liquid and solid chemical substances require a high degree of precision, safety and reliability. IFA Technology has an extensive portfolio of gravimetric and volumetric mixing and dosing systems. Our systems meet all country- and customer-specific requirements for explosion, emission and environmental protection as well as for material resistance and product compatibility. Furthermore, our mixing and dosing systems, especially in batch operation, offer a high degree of production reliability, which is guaranteed by minimisation of material contamination, reproducibility and detailed documentation.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

In the building materials industry and building materials chemistry, the demands placed on individual process sequences are constantly increasing. Higher product qualities and product demands require an optimal interaction of the different systems within the production plant. With our special know-how in the areas of storage, conveying, dosing, weighing and mixing of liquids and solids, we can create a customer-specific solution concept for you. We consider your individual requirements and build customised plants and systems for base materials and building materials.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA shows you different ways to reduce product rejects: Increase the automation level: If the level of automation gets increased, human errors are reduced, thus avoiding rejects (e.g. digital order processing, automated quality control, immediate error messages by email, SMS, etc.). Analyse production processes: Rethink your production processes in order to increase the product usability (e.g. hardener dosing directly at the consumer). Remove contaminants: Eliminate contamination from the use of the final products.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

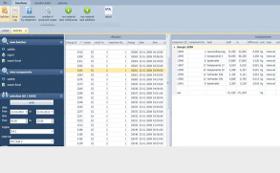

The aspects of data acquisition, tracing and data processing also play an increasingly important role in industrial plants. In the age of Industrie 4.0, we have been offering "big data" for years. In our plants and systems, we use database systems that perform several tasks simultaneously. Modern databases, such as MS SQL or Oracle, offer flexible interfaces which supply the plant with order data from the ERP system and enable the transmission of consumption data from the plant to the ERP system. IFA Technology has developed the GraviSoft software for archiving and recording data and errors in an SQL database. In addition to the usual features, the GraviSoft 3.0 version also offers new, future-oriented highlights, for instance

Request for a quote

IFA TECHNOLOGY GMBH

Germany

Product formulas are mostly complex in nature. Therefore you can create and save up to 200 recipes with 25 steps each with the IFA standard recipe control. If you need more functions or steps, you can extend the recipe control with a database system according to your requirements. We work with standard programs like "Siemens-Batch" or "In-Batch". A user-friendly editor allows you to easily copy and paste recipes and add or remove individual components.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

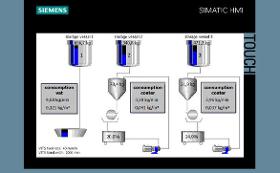

What you can see is easier to understand. Therefore we visualise IFA Technology plants and systems with "WinCC", "WinCC Flexible", "WinCC TIA", "InTouch" or "Panelview". Special programs are also possible. These tools provide a reliable interface between the user and the machine (user interface) and allow a quick overview of the most important control parameters of the plant or system. The integrated error reporting system facilitates troubleshooting and reduces the time required for this to a minimum. Language toggling allows the operator to choose between different languages for the user interface.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

The control or PLC programming of your plant or system can be set up centrally or peripherally and thus adapted to your requirements. This enables maximum performance at the lowest possible cost. With the Siemens Simatic S7 series and the Allen Breadly PLCs such as Control Logix and Compact Logix, IFA Technology offers a long-term compatible system control that is scaled to your needs. Our experienced programmers develop structured and reproducible PLC programs that guarantee fast troubleshooting and reduce machine downtimes to a minimum. Plant modifications or extensions are also possible at any time due to the components used and the control structure. With the help of modern interfaces, all plant components can be networked, so that the plant or system can be integrated into your company network as desired.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

We attach great importance to ease of operation and versatile plant functions. The control technology of our plants and the regulation technology for fully automated systems is always executed with the highest degree of accuracy and care. The communication between the plants and systems (PLC/PC/panels) can be implemented with various interfaces such as Profinet, Profibus, ASi-bus, Ethernet network, etc. Remote maintenance or connection to an ERP system via the Internet are also possible.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

Careful planning and many years of experience are necessary to build functional and reliable switchgear in the long term. We take over the entire conceptual design of control cabinets: from electrical planning with EPLAN P8 through the complete procurement of high-quality components to assembly. IFA Technology generally works according to EN/DIN/VDE standards and with the latest electrical components. We are UL and UL-NRBX certified for plants and systems located in North America. We create an E-P&ID diagram for each plant or system. This makes the relationship between electrical and mechanical components transparent and simplifies maintenance and troubleshooting. Our circuit diagrams are drawn up in accordance with the VDE0113/EN-60204-1 directives or - for the North American market - in accordance with the NFPA79 and UL508A directives. The electrical documentation is available in all common foreign languages.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

We consider your individual requirements on process automation and build customised plants and systems for you. For us, process automation means completely mapping all process states, recording all alarm messages and securing access via passwords. By means of process visualisation, the monitoring of your plant or system takes place directly on site and/or from your control room. The plants and systems from IFA Technology enable you to optimally compose your mixtures by means of recipe control. In addition to the dosing quantities, other parameters such as stirring times can also be defined. Comprehensive recording of all batch data in a database makes it possible to output automatic order data in conjunction with your merchandise management system.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers you customised solutions for water treatment using mineral wool wash water plants. Benefit from our extensive experience in the field of insulating materials. Functions of mineral wool wash water plants: Planning, design, construction, assembly and commissioning of systems for the collection and treatment of waste water from the production process Multi-stage filtration and purification of the water using settling tanks with agitators, screening machines, drum filters and hydrocyclones

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology considers your individual requirements on resin synthesis and builds customised condensation plants for you. The manufacture or production of resins and glues, also known as resin synthesis or resin polymerisation, is a lengthy and complex process. Based on melamine, urea or phenol, we enable the production of your raw resins with a condensation process at boiling point, including the necessary technologies and recipes as well as product optimisation by our partners. IFA Technology offers you a complete condensation plant for resin synthesis, including raw material storage and raw material dosing, heating and cooling systems, reactors with condensers and a tank farm. Integrated is the adjustment of the pH value as well as a viscosity control, which takes place fully automatically if desired. For this purpose we offer an intelligent process control system for a safe reaction sequence.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology considers your individual requirements on waste water treatment and builds customised flocculent systems for you. Flocculent systems for waste water treatment can be used for various fields of application - from the dosing of additives to the filtration of the flocculent. Such a flocculent system can, for instance, be used as a fully automated three-chamber system to produce a solution from dry polyelectrolytes. Flocculent systems from IFA Technology are always implemented according to your individual wishes. In addition to stationary systems, container solutions are also possible.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology considers your individual requirements on process and quality monitoring and builds customised viscosity control systems for you. Viscosity control systems are mainly used for monitoring and optimising processes and product quality. In accordance with your needs IFA Technology implements complete plants which are equipped with mixing tanks, dosing units and consumption data acquisition. The viscosity sensors are used as rotation sensors, inline sensors or resonance frequency sensors, depending on the area of application. The connected controller is freely parameterisable and can be connected directly to higher-level control systems via an interface.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology considers your individual requirements and builds customised mixing systems for you. Powder dispersion units are used for agglomerate-free wetting of powdery substances with liquid substances. Our mixing systems are adapted to your needs and generate a vacuum using a rotor-stator principle. This sucks in the powder and mixes it directly in the liquid flow in the mixing unit. Even difficult materials can be processed without any problems thanks to the dust-free suction with the aid of guide jet mixers or rotor-stator mixing units. In addition to the automated feeding of liquid and powdery materials, the complete system from IFA Technology includes a dispersion unit with mixing tank and purification system. The dispersion system can be implemented in batch operation (as homogeneous as possible mixing of the components) or inline (fully continuous mixing of the components). Variants directly in the mixing tank are alternatives to conventional agitators.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

The microdosing technology of IFA Technology guarantees that raw material dosing happens according to a fixed sequence with highest dosing accuracy. We consider your individual requirements and the local conditions in order to develop customised dosing systems for you. Our dosing systems can also be integrated into existing production plants. The adjustable dosing parameters enable optimum dosing results to be achieved for the various raw materials. Do you have any questions on microdosing technology? If you are interested in our technology, please do not hesitate to contact us! We look forward to hearing from you

Request for a quote

IFA TECHNOLOGY GMBH

Germany

Our experience in agitator technology offers you a professional layout of agitators in order to prepare your products according to your requirements. We consider your individual requirements and build customised agitators for you – for homogenising, emulsifying, aerating, grinding, suspending, dispersing or mixing and dissolving your solids and liquids. Do you have any questions on agitator technology? If you are interested in our technology, please do not hesitate to contact us! We look forward to hearing from you

Request for a quote

IFA TECHNOLOGY GMBH

Germany

Energy systems for industrial plants can sometimes be expensive to maintain. This is why we already pay attention to economic solutions during the planning and conception of your plant. Our heating and cooling systems are needs-based, individual solutions for seasonal and user-related requirements. Heat transfer media such as water, air or oils are heated by means of large-capacity water boilers, high-speed steam generators or thermal oil systems. In the heating systems from IFA Technology, the subsequent heat transfer takes place through half-tube coils welded onto the jacket, heat exchangers, heat transfer plates (thermoplates) or electrical heating cables.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

Customer-specific requirements require customised solutions. We would be pleased to advise you personally and develop together with you a customised plant or system for your special requirements. In addition to prototypes and standard plants and systems, we also implement mobile mixing systems. We deliver space-saving, transportable plants and systems according to your wishes. Do you have any questions on customer-specific solutions? If you are interested in our systems, please do not hesitate to contact us! We look forward to hearing from you

Request for a quote

IFA TECHNOLOGY GMBH

Germany

We consider your individual requirements and build customised batching plants for you. Batching plants are an important component in the system processes for the delivery, storage, dosing and mixing of raw materials and form the basis for a high-quality end product. In addition to the storage of raw materials, this also includes the processing of individual components or the finished product. IFA Technology offers you turnkey and customised complete plants in various designs, which are specially manufactured for the chemical and building materials industries. We design batch plants as tower plants that make predominant use of gravity transport or as series plants with belt transport.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

Reaction systems from IFA Technology are designed and built to customer specifications and can be tailored to your individual requirements and wishes. For example, the required individual components in the reaction vessel (reactor) can be added manually or automatically. The gravimetric or volumetric measurement ensures that the components correspond at all times to the product recipe stored in the programmable logic controller (PLC). This ensures a high level of safety with regard to product quality and reproducibility in batch operation. The reactions taking place in the reaction system are also always associated with considerable temperature and pressure fluctuations (exothermic or endothermic reactions). In the development and construction of system that operate with positive pressure or vacuum, we draw on our many years of experience. We offer manual or fully automated reactors, pH measuring systems and viscosity control systems.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology considers your individual requirements and builds customised explosion-proof systems for you. Our explosion-proof systems are in use all over the world. As a supplier of equipment for processing explosive liquids and solids (dusts), we work in accordance with the official explosion protection regulations. These include, among others, the ATEX Directive 2014/34/EU of the European Union. If necessary, systems are subjected to an individual acceptance test by a notified body. We attach particular importance to primary and secondary explosion protection, so that measures of tertiary explosion protection can be largely dispensed with. Do you have any questions on explosion-proof-systems? If you are interested in our systems, please do not hesitate to contact us! We look forward to hearing from you

Request for a quoteResults for

Goods handling - Import exportNumber of results

65 ProductsCompany type