- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- composites

Results for

Composites - Import export

GLT BEARINGS GMBH

Germany

Rolled composite plain bearing | Maintenance-free | Steel / graphite bronze | With embedded solid lubricants GAP-MET®/S is a maintenance-free composite plain bearing. However, oil or grease lubrication is possible. High load capacity and strength, for all slow movement types, suitable for contaminated environments, no moisture absorption, good chemical resistance. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing with lubrication pockets/ copper-plated steel & CuSn10Pb10 & graphite | maintenance-free | DIN 1494 / ISO 3547 BIV-LUB® is a maintenance-free composite plain bearing with solid lubricant depots. Initial lubrication is necessary! High load capacity with low wear, very suitable for low sliding speeds and oscillating movements. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing with lubrication pockets/ copper-plated steel & AlSn20Cu | Low-maintenance | DIN 1494 / ISO 3547 For high sliding speeds, optimum sliding behaviour with good lubricant supply. BIV-MET®/A is a composite sliding bearing requiring maintenance; oil or grease lubrication is needed. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing with lubrication pockets/ copper-plated steel & CuSn10Pb10 | Low-maintenance | DIN 1494 / ISO 3547 BIV-MET® is a low-maintenance bronze plain bearing. However, initial lubrication is required—both oil and grease lubrication are possible. Due to the lubricant depots, the relubrication intervals are greatly reduced! For high loads and oscillating movements as well as for rough operation and temperature load. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing with lubrication pockets/ CuSn8P & graphite | maintenance-free | DIN 1494 / ISO 3547 BRO-LUB is a maintenance-free bronze plain bearing with solid lubricant depots. Initial lubrication is necessary! High load capacity with low wear, very suitable for low sliding speeds and oscillating movements. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing steel / POM | low-maintenance | With lubrication pockets | DIN 1494 / ISO 3547 POM-MET® is a low-maintenance composite sliding bearing with a POM coating. Initial lubrication is required. Both oil or grease lubrication are possible. Due to the lubricant pockets, relubrication intervals are significantly reduced! Suitable for all sliding movements, good load capacity, robust and resistant to dirt. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Rolled composite plain bearing steel / PTFE coated | Maintenance-free dry plain bearing | DIN 1494 / ISO 3547 TEF-MET/B is a versatile, corrosion-resistant dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, additional lubrication is possible in principle! For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Rolled composite plain bearing steel / PTFE coated | Maintenance-free dry plain bearing | DIN 1494 / ISO 3547 TEF-MET is a versatile dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, additional lubrication is possible in principle! For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

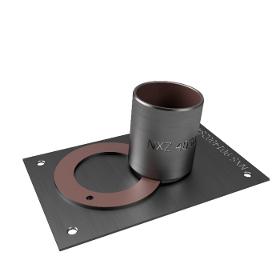

Filament-wound composite bearing with self-lubricating inner | Surface backed with a high-strength | Maintenance-free | With a sliding layer of PTFE with lubricant additives COM-KU®/M is a self-lubricating and maintenance-free plastic plain bearing. Using a heavy-duty glass fibre fabric combined with a selected binder resin helps to increase the mechanical properties, pressure further and wear resistance of this bearing type. The special lubricant additives and the PTFE in the sliding layer reduce the friction coefficient, optimising the wear behaviour and thus the material's service life as a dry sliding bearing. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing Stainless steel / PTFE coated | Maintenance-free dry sliding bearing | Corrosion resistance | Chemical resistance | DIN 1494 / ISO 3547 NOX-MET® is a versatile, corrosion-resistant dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, additional lubrication is possible in principle! For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing steel / Special PTFE coated Maintenance-free dry sliding bearing | DIN 1494 / ISO 3547 TEF-MET/P is a versatile dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, it is very well suited for lubricated applications (e.g. hydraulic oil lubrication). For technical details, please visit the product page on our website!

Request for a quote

SGL TECHNOLOGIES GMBH

Germany

In our weaving facility, we produce a wide range of SIGRATEX woven fabrics and tapes. We use 1k, 3k, 6k, 12k, and 24k carbon fiber tows as the material basis. In hybrid woven fabrics, we also process glass and aramid fibers.

Request for a quote

ALLVAC FOLIEN GMBH

Germany

The AVB is a special top film characterised by its excellent flatness, high degree of transparency, outstanding puncture resistance and seal strength in the hot tack state. The AVB can be processed both as top film and bottom film on flow pack machines and is also suitable for pasteurisation, due to its high level of temperature tolerance. It has a wide range of application. In addition to vacuum or MAP packaging in the food or non-food sector, they are also used as tray top films with antifogging properties. They also serve as ripening packs for cheese maturation as well as for cooking processes and microwave heating. Features of AVB: High quality Medium and high barrier against oxygen and water vapour Highly transparent Excellent sealing properties Hot Tack Increased puncture resistance AVB-FAMILY STRUCTURE STANDARD THICKNESSES AVB 9 – 18 Layer PA/PE Blown film 50 - 180my AVBE 9 - 18 Layer PA/PE Blown film with EVOH High barrier 50 - 220my AVBEF 9 Layer PA/PE Blown film

Request for a quote

ALLVAC FOLIEN GMBH

Germany

The AV is the classic of our variety of composite films featuring a wide range of applications. With its 5-7 PA/PE layers, available in thicknesses from 70 to 300my, it runs perfectly as a bottom film on thermoforming packaging machines, due to its excellent formability. This standard film offers a medium barrier against oxygen and water vapour. Its high degree of transparency and gloss make the products stand out at the point of sale, while its excellent sealing properties, puncture resistance and exceptional mechanical strength are equally impressive. The AV tolerates temperatures of up to 70°C for up to 2 hours and is therefore also suitable for pasteurisation. Features of AV: Medium barrier against oxygen and water vapour Highly transparent Very glossy Excellent sealing properties Increased puncture resistance

Request for a quote

ALLVAC FOLIEN GMBH

Germany

Our flexible PA/PE medium barrier multilayer bag films have been specially developed for bag production. Multilayer barrier films are manufactured from polyamide and polyethylene in tandem- as well as in coextrusion processes. The films’ high stiffness values increase the output in the bag production and thus offer an impressive economic advantage. Specially equipped and lightly powdered sealing layers facilitate the opening of the bag by the consumer thus making them a very popular product. A versatile assortment Our extensive range of PA/PE medium barrier multilayer bag films offers the right variant for every desired application – no matter whether fresh food needs to be packaged hygienically and safely for transport or for cheese maturation. In addition to the high quality, you benefit from fast order processing, short delivery times and maximum security of supply. Innovation, experience and competence in one film

Request for a quote

ALLVAC FOLIEN GMBH

Germany

The AVBHT is a flexible PP/PA/PE medium barrier high temperature blown film by ALLVAC characterized by its layers. This type of film is perfectly suitable for cooking, pasteurising, sterilising and microwave heating as well as for temperature applications of longer duration, such as Sous-Vide cooking. Classic applications include the packaging of Tofu, potatoes and ready meals. AVBHT films tolerate temperatures from -40°C to +121°C without delamination, loss of tightness or leakage. Features of AVBHT: Medium barrier Additional polypropylene layer Temperature tolerance from -40°C to +121°C AVB-FAMILY STRUCTURE STANDARD THICKNESSES AVBHT (C) 9-Layer PP/PA/PE Blown film, sterilisation up to 121°C (tinted) 80-170my

Request for a quote

ALLVAC FOLIEN GMBH

Germany

The flexible, coextruded PA/PP medium barrier high temperature composite films by ALLVAC distinguish themselves by integrated polypropylene layers. The resulting highly transparent film is ideal for temperature applications such as cooking, pasteurising, sterilising and microwave heating. It is convincing even after thermoforming processes due to its very high puncture resistance as well as suitable for temperature applications of longer duration, such as Sous-Vide cooking. Classic applications of this type of film are the packaging of Tofu, beetroot, potatoes and ready meals. PA/PP medium barrier high temperature composite films tolerate 121°C Due to their versatility under heat, our PA/PP medium barrier high temperature composite films have established their traditional place in canteen kitchens but increasingly also in private households. Pre-prepared food and ready meals receive their ideal packaging. Their advantages have led to an undreamt-of spread: they are quickly...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALLVAC FOLIEN GMBH

Germany

Flexible, coextruded PA/PE (EVOH) high barrier composite films from ALLVAC ensure long shelf life and perfect aroma protection. Polyamide and polyethylene as film base guarantee high puncture resistance while protecting the packaged goods from moisture as well as from any loss of product fluids. EVOH (ethyl vinyl alcohol) is a PE-based aroma barrier which guarantees the preservation of the packaged product’s taste. Baked rolls or tasty fresh pasta receive reliable protection from moisture and oxygen. Our composite films are the solution to provide your products with a long shelf life, aroma preservation and, at the same time, a sales-promoting appearance at the point of sale. PA/PE (EVOH) High barrier composite films not only for small baked rolls We recommend our PA/PE (EVOH) high barrier composite films not only for the packaging of bread and bakery products. Packaging for sausage products in modified atmosphere (MAP) also benefits from our high barrier composite films, as...

Request for a quote

ALLVAC FOLIEN GMBH

Germany

The AV is the classic of our variety of composite films featuring a wide range of applications. With its 5-7 PA/PE layers, available in thicknesses from 70 to 300my, it runs perfectly as a bottom film on thermoforming packaging machines, due to its excellent formability. This standard film offers a medium barrier against oxygen and water vapour. Its high degree of transparency and gloss make the products stand out at the point of sale, while its excellent sealing properties, puncture resistance and exceptional mechanical strength are equally impressive. The AV tolerates temperatures of up to 70°C for up to 2 hours and is therefore also suitable for pasteurisation. Features of AV: Medium barrier against oxygen and water vapour Highly transparent Very glossy Excellent sealing properties Increased puncture resistance

Request for a quote

ALLVAC FOLIEN GMBH

Germany

The AVGT is a special bottom film which is particularly used for box-shaped forms in thermoformed packaging. It is suitable for all products with a defined volume and offers an increased level of puncture resistance. Its high transparency makes it ideal for product presentation at the point of sale, as it is applied in thermoforming high-quality special packaging. The AVGT can also be used to package food or non-food products under vacuum or MAP. Its excellent sealing properties, even with contaminated sealing surfaces, should also be emphasised. Features of AVGT Medium barrier against oxygen and water vapour Very high degree of transparency Excellent sealing properties Hot tack High mechanical strength Increased puncture resistance Optimum thermoforming properties AVGT-FAMILIY STRUCTURE STANDARD THICKNESSES AVGT 7 Layer PA Special / PE Special film 120 - 300my

Request for a quote

ALLVAC FOLIEN GMBH

Germany

The flexible PA/PE medium barrier composite films are suitable for classic applications such as thermoforming. Each layer performs an important function: The PA layer is the crucial factor for the mechanical strength of the packaging. Working as a barrier layer, it seals in the aroma and prevents the penetration of oxygen, thereby extending the shelf life of your product. The PE layer on the inside of the packaging functions as a sealing medium and is decisive for providing airtight seams and a proper skin sealing. It serves as a moisture barrier and, although it protects your product from drying out, it also prevents the uncontrolled absorption of moisture. The tie layer between the PA and PE layers has the task of reliably tying them together so as to prevent delamination, even at high or varying temperatures. Excellent puncture resistance and wide sealing range Co-extruded composite films by ALLVAC consist of up to 11 layers of polyamide and polyethylene

Request for a quote

ALLVAC FOLIEN GMBH

Germany

Allflex B is a member of the product family of flexible PA/PE medium barrier multilayer bag films produced by means of coextrusion. The polyamide and polyethylene multilayer barrier film offers excellent stiffness values which have a positive effect on the output during bag production. The film is powdered lightly, making it thus easier for the consumer to open the bag. The allflex B 11-layer film is available in thicknesses from 65my to 85my and scores well in packaging processes under vacuum or MAP in both the food and non-food sectors. Due to its temperature tolerance it is also ideal for pasteurisation and microwave applications. Features of allflex B: Medium barrier against oxygen and water vapour High degree of transparency Excellent sealing properties Increased puncture resistance

Request for a quote

ALLVAC FOLIEN GMBH

Germany

The allflex UHT is an 11-layer PA/PP cast coextrusion film suitable for sterilising sweet corn or beetroot, due to its temperature tolerance of up to 121°C. The vegetables can be treated at this heat for up to one hour. The film’s good transparency and increased puncture resistance ensure the products an appetising appearance on retail shelves. Advantages of allflex UHT in an overview: Suitable for sterilising at 121°C for 1 hour Increased puncture resistance Good transparency

Request for a quote

ALLVAC FOLIEN GMBH

Germany

The allflex UHG is an Ultra-High-Gloss 11-layer PET/PA/PE Cast Coextrusion film and available in thicknesses of 200my, 250my, 300my and 350my. It is characterized by its extremely high level of transparency and an exceptional gloss. It is therefore the perfect packaging solution for spareribs. Its increased puncture resistance, unsurpassed formability and excellent sealing properties are particularly appreciated among our customers. Advantages of allflex UHG in an overview: Extremely high level of transparency and gloss Improved formability Increased puncture resistance Excellent sealing properties

Request for a quote

ALLVAC FOLIEN GMBH

Germany

The allflex UHR is a Special Ultra-High-Resistance 11-layer PA/PP/PA/PE cast coextrusion film available in thicknesses of 250my, 300my and 350my. This particularly robust, highly transparent and optimally formable film is ideal for packaging Tyrolean Speck attractively. The packaging result makes your products irresistible at the point of sale. The advantages of allflex UHR at a glance: Extremely high transparency Improved formability Increased puncture resistance Excellent sealing properties

Request for a quote

ALLVAC FOLIEN GMBH

Germany

High levels of transparency and puncture resistance are the most important features of ALLVAC’s flexible, coextruded PA/PP/PA/PE medium barrier composite films. This type of film is composed of polyamide, polyethylene and, additionally, polypropylene (PP). It is a thermoplastic, semi-crystalline and non-polar plastic with similar properties to polyethylene, but is harder and more heat-resistant. Films containing this additive are ideal for extreme thermoforming applications and offer reliable product protection. They are primarily used for packaging smoked or air-dried hams such as Black Forest ham, Prosciutto Crudo, Parma ham, Jamon Iberico or Serrano ham but also for classic applications such as packaging spareribs or bones. Even products that are deep-frozen retain their appetising appearance at the point of sale while the packaging is a reliable protection. BRCGS certified and free from plasticizers From development to extrusion and up to confectioning, the entire process...

Request for a quote

ALLVAC FOLIEN GMBH

Germany

The AVGTS is a special bottom film with best sealing properties and excellent meat adhesion, which is owed to integrated ionomers composed of ethylene methacrylic acid copolymers. The resulting ionic crosslinks are reversible as they dissolve at usual processing temperatures and form again during the cooling phase. The excellent recovery properties and optimal meat adhesion of the AVGTS are particularly beneficial for the production of cooked ham, but also very much in demand for packaging fresh meat. This innovative film with a heat tolerance of maximum 76°C allows gentle cooking of products for up to 12 hours and convinces with minimal jelly or juice separation as well as very good recovery properties. The AVGT is perfectly suitable for products with a defined volume requiring box-shaped forms.

Request for a quote

ALLVAC FOLIEN GMBH

Germany

The AVS is a 5-7 layer PA/PE/SURLYN® film used on thermoforming packaging machines as both top and bottom film. Integrated ionomers ensure excellent meat adhesion and optimum sealing properties, even if the sealing surface has been contaminated with water, blood, fat or product juices. The ionic crosslinks are reversible as they dissolve at usual processing temperatures and form again during the cooling phase. This type of film features both excellent recovery properties and meat adhesion and is therefore ideal for the production of cooked ham. Its temperature tolerance allows cooking processes above 76°C – even for up to 12 hours. Features of AVS: Excellent meat adhesion Reduced jelly separation during cooking Medium barrier against oxygen and water vapour Extremely high transparency Outstanding sealing properties, even with contaminated sealing surfaces IONOMER-FAMILY STRUCTURE STANDARD THICKNESSES AVGTS 7 Layer PA Special/PE/SURLYN® film 230my AVS 5 - 7 Layer PA/PE/SURLYN® film

Request for a quote

ALLVAC FOLIEN GMBH

Germany

Allflex ION is a special IONOMER 11-layer PA/PE/SURLYN® cast coextrusion film. It is ideal for producing cooked ham. Its main characteristic is excellent meat adhesion during the cooking process. Allflex ION is particularly popular as it prevents practically any jelly from forming on the product surface. Advantages of allflex ION at a glance: Excellent meat adhesion during cooking process Reduction of jelly formation High transparency Improved sealing properties

Request for a quoteResults for

Composites - Import exportNumber of results

34 ProductsCompany type